Preparation method for regulating and controlling K2Ti4O9 band gap by using transition metal ions and photocatalytic application

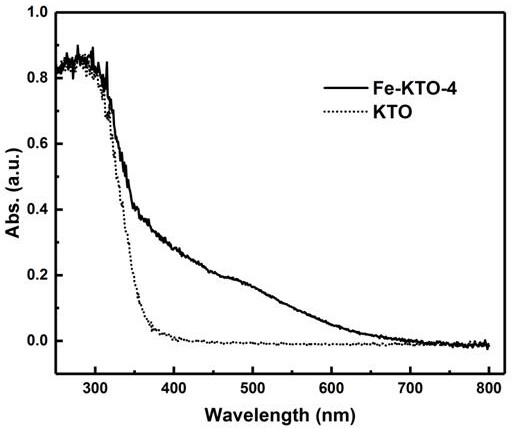

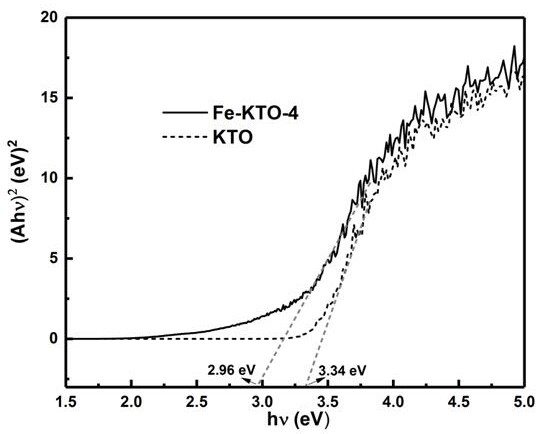

A technology of transition metal ions and ions is applied in the field of photocatalytic degradation, which can solve the problems of low utilization rate of visible light, and achieve the effects of improving photocatalytic efficiency, simple method, and efficient charge-hole separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Weigh titanium dioxide and potassium carbonate according to the ratio of Ti:K=2:1, mix and ball mill for 12 hours, heat in an air atmosphere at 1000°C for 1 hour, then disperse the product in dilute hydrochloric acid, wash and dry to obtain K 2 Ti 4 o 9 powder;

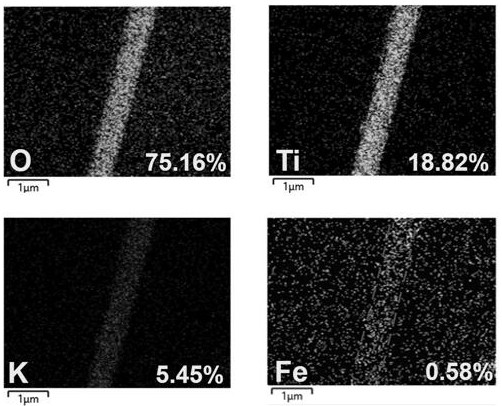

[0022] (2) Weigh 0.162g iron nitrate nonahydrate (Fe(NO) 3 9H 2 O) be dissolved in 20ml deionized water and be configured to contain 0.02mol / L Fe 3+ ion solution, and add step (1) gained K 2 Ti 4 o 9 Powder 1g, stirred for 24h, filtered and dried to obtain Fe-KTO material A;

[0023] (3) Take 0.1 g of the Fe-KTO material A obtained in step (2) and disperse it in 20 ml of methylene blue solution with a concentration of 20 mg / L, and then place the mixture under direct sunlight at 13-16 in fine weather for photocatalysis reaction.

Embodiment 2

[0025] This embodiment includes the following steps:

[0026] (1) Weigh titanium dioxide and potassium carbonate according to the ratio of Ti:K=2:1, mix and ball mill for 12 hours, heat in an air atmosphere at 1000°C for 1 hour, then disperse the product in dilute hydrochloric acid, wash and dry to obtain K 2 Ti 4 o 9 powder;

[0027] (2) Take 0.1g copper sulfate pentahydrate (CuSO 4 ·5H 2 O) be dissolved in 20ml deionized water and be configured to contain 0.02mol / L Cu 2+ ion solution, and add step (1) gained K 2 Ti 4 o 9 Powder 1g, stirred for 24h, filtered and dried to obtain Cu-KTO material B;

[0028] (3) Take 0.1g of the Cu-KTO material B obtained in step (2) and disperse it in 20ml of methylene blue solution with a concentration of 20mg / L, and then place the mixture under the direct sunlight of 13-16 in fine weather for photocatalysis reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com