Environment-friendly PU leather

An environmentally friendly, water-based polyurethane technology, applied in the field of PU leather, can solve problems such as harming the human body, harming the human body, polluting the environment, etc., achieving good moisture permeability and air permeability, and improving the effect of firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

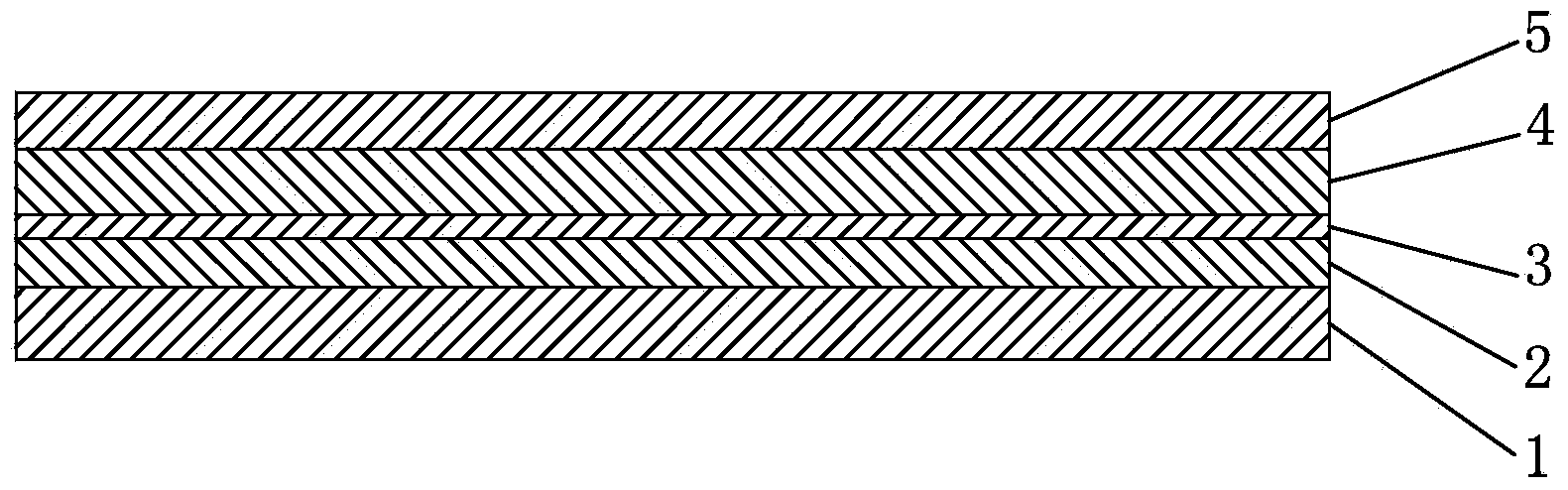

[0013] like figure 1 As shown, the present invention includes a base fabric layer 1 on which a primer layer 2 composed of cationic water-based polyurethane is compounded, and the primer layer is coated with an adhesive layer composed of anionic water-based polyurethane. Layer 3, a middle coating layer 4 composed of cationic water-based polyurethane is compositely arranged on the adhesive layer, and a water-based polyurethane surface layer 5 is compositely arranged on the middle coating layer. The cationic waterborne polyurethane is a hydroxyl silicone oil-modified cationic waterborne polyurethane, and the cationic waterborne polyurethane contains polydimethylsiloxane toluene carbamate. The base fabric layer 1 is made of sea-island nylon superfine fibers with a fineness of 5-7 denier and impregnated with polyurethane slurry. The anionic wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap