A continuous lead device

A technology of continuous leads and guide parts, applied in the direction of electrical components, circuits, cables/conductors, etc., can solve the problems of cable or wire damage, inaccurate leads, large tension, etc., and achieve low manufacturing cost, simple structure, Avoid the effect of breaking the lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

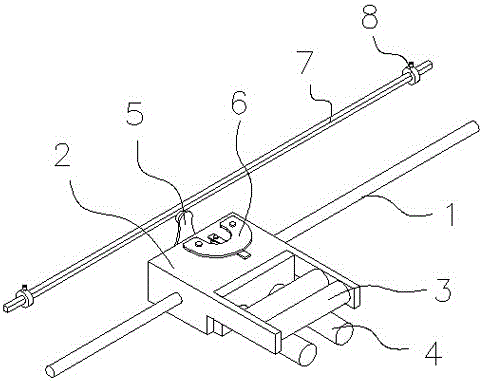

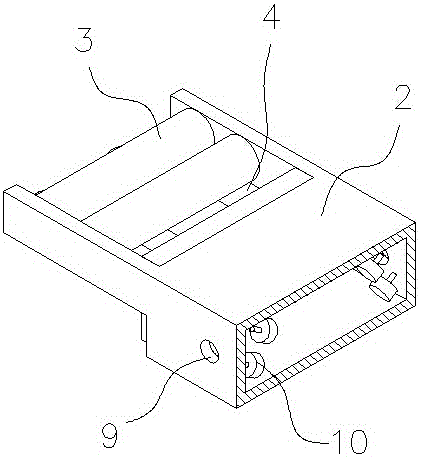

[0025] A continuous wire lead device, comprising a driving rod 1, on which a main driving block 2 that can move continuously on the driving rod 1 is arranged, and a driving mechanism is obliquely arranged at the joint between the main driving block 2 and the driving rod 1, and the main driving There is a driving cavity in the block 2, and two sets of driving wheels 10 are arranged in the driving cavity, which are axially inclined to the axial direction of the driving rod 1. A bearing hole 9 for passing the driving rod 1 is arranged in the middle of the main driving block 2, and the driving rod 1 passes through The bearing hole 9 runs through the drive cavity. The driving wheels 10 are respectively a left driving wheel and a right driving wheel, and only one group of driving wheels 10 is at most abutting against the surface of the driving rod 1 at any moment. The left driving wheel and the right driving wheel both include an upper upper guide wheel and a lower lower guide wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com