Lead-acid storage battery housing structure

A technology of lead-acid battery and shell structure, which is applied in the direction of structural parts, battery cover/end cover, battery pack parts, etc., which can solve the problems of wasting materials and manpower, increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments and positive effects of the present invention will be further described below.

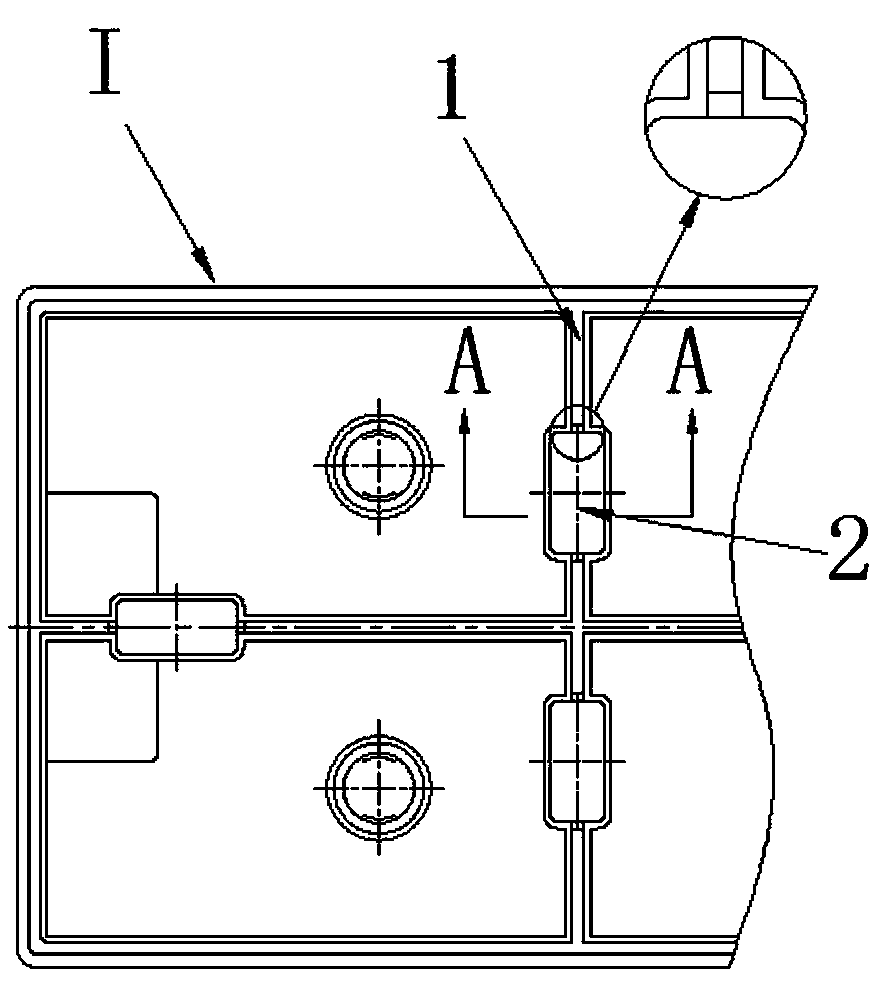

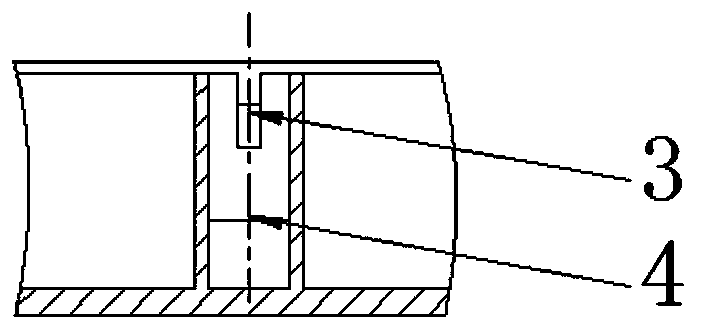

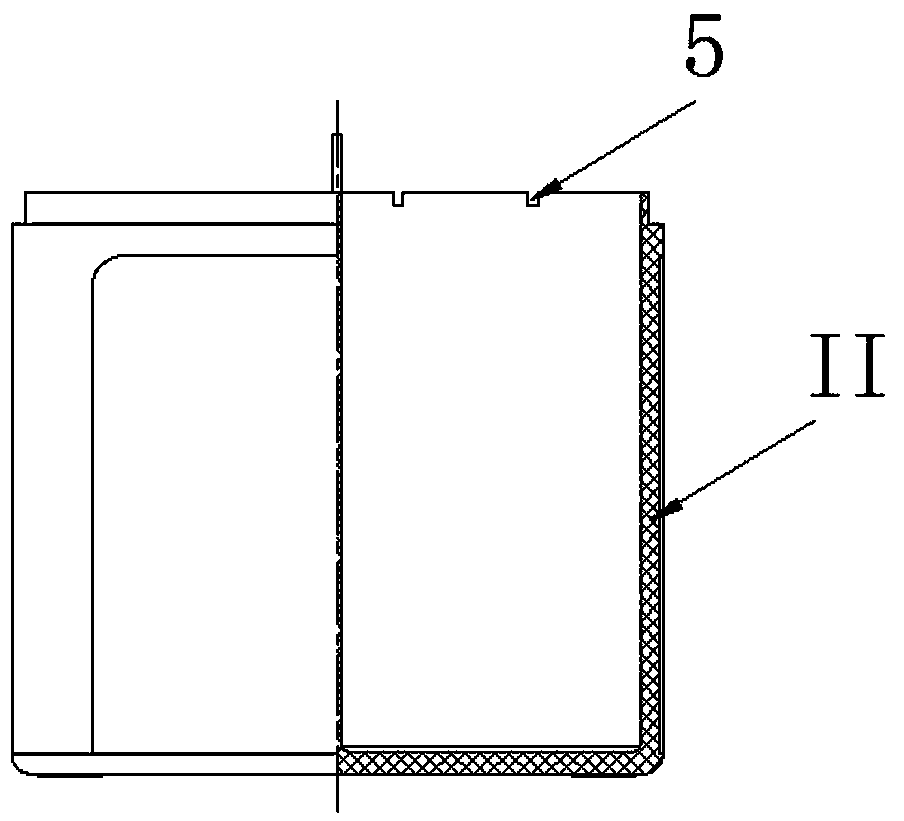

[0013] As shown in the figure, a boss 3 is added in the U-shaped groove at the joint between the groove 2 on the back of the upper cover 1 and the U-shaped groove 1, and there is a boss 3 on both sides of each groove 2, and the height of the boss is U-shaped. About half of the depth of the groove; a gap 5 is opened at the barrel body II corresponding to the barrel wall, the width is slightly greater than the thickness of the boss 3, and the depth is consistent with the height of the boss, so as to ensure that the cooperation between the barrel and the upper cover is not affected.

[0014] When sealing with glue, first pour the glue into the U-shaped groove 1 of the upper cover, the height of the boss is the height of the poured glue, and the excess glue will flow into the groove 2 to ensure that the amount of glue is not excessive. Then pour the glue into the groove 2, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com