A pile bearing variable stiffness reinforced cushion composite foundation and its construction method

A technology of reinforced cushion and composite foundation, which is applied in foundation structure engineering, sheet pile wall, building, etc., can solve the problems of insufficient soil bearing capacity between piles, difficult to control settlement, limited height of embankment, etc. The quality of the piles is guaranteed and the effect of reducing the differential settlement of the pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

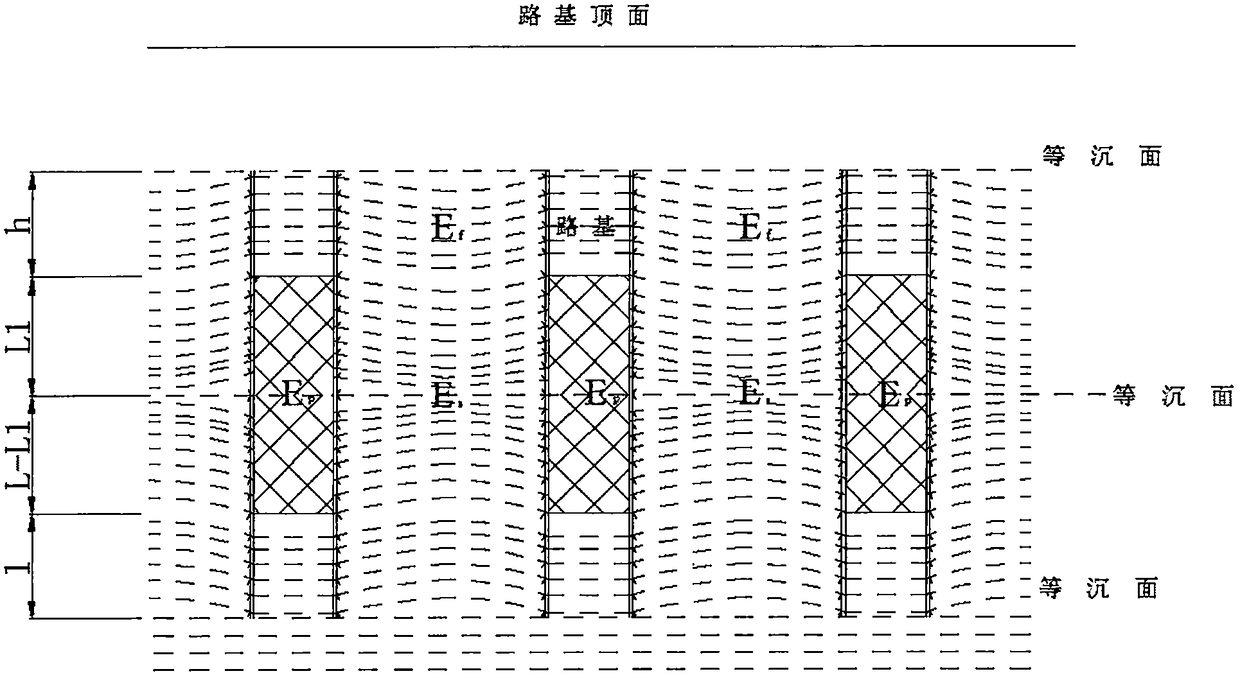

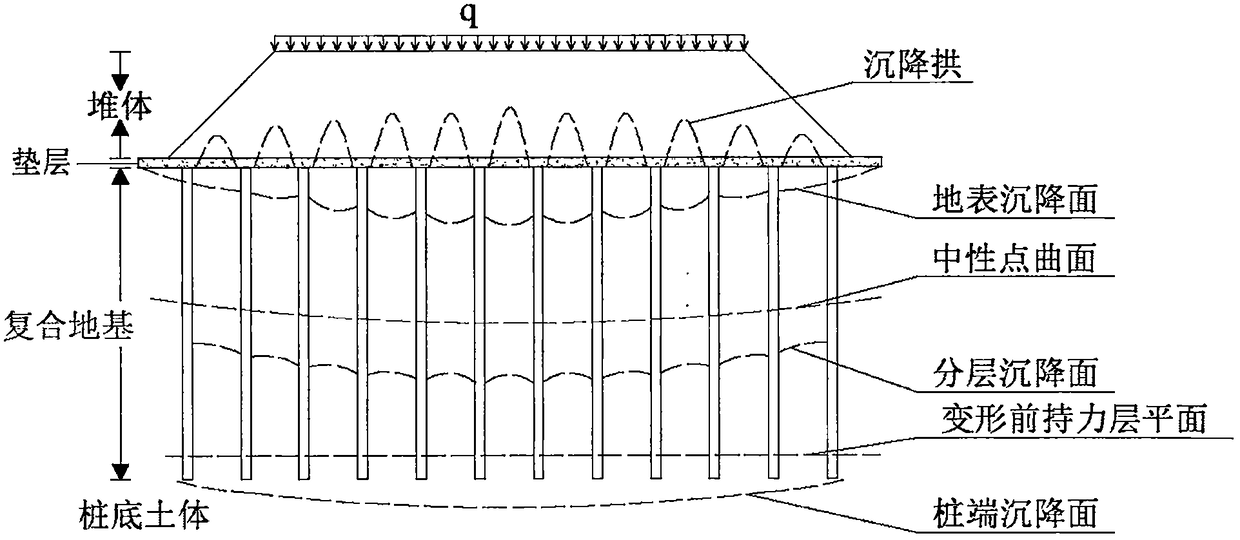

[0057] The thickness of the soft soil on a site is 11m, including silt, fine silt sand, and clay layers. The designed pile length of the invention is 16m and prestressed pipe piles are used. The pile diameter is 400mm and the spacing is 2.5m. The pipe piles penetrate the soft soil layer and enter the lower lying area. Sandy clay layer 5m, 200mm thick sand and gravel layer 2 is laid after leveling the site; the first layer of geogrid 31 is laid after leveling and compaction; 150mm thick gravel layer 32 is laid on the first layer of geogrid 31; After solidification, the second layer of geogrid 33 is laid, and 150mm thick cement stabilized gravel layer 4 is spread on the second layer of geogrid 33, and compacted; after forming a pile-bearing variable stiffness reinforced cushion composite foundation, set it on top Fill the soil layer or directly set the surface layer to build grain depots, storage yards, etc., which meet the design functional requirements.

[0058] In the formation ...

Embodiment 2

[0060] It is proposed to build a high-grade road of 100km in soft soil area with a base width of 20m. Assuming the deep mixing pile method is used for foundation treatment, and the pile spacing is the usual 1.2m, 1.4 million piles are needed, and 700 million piles are required to be invested. Yuan Renminbi; however, if designed according to the results of the present invention, the pile spacing is appropriately increased while ensuring driving safety, the foundation treatment costs can be greatly reduced. According to calculations, adjusting the pile spacing to 2.5-3.0m can reduce the investment rate by 30%-40%, and the pile construction quality is also guaranteed.

Embodiment 3

[0062] The test section of an expressway, with a total length of 148.5m, is divided into four bid sections. The four sections have different treatment methods. Each section has a key section and embedded monitoring instruments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com