Rotary type safety power strip

A rotary and plug-in technology, applied in the field of plug-in, can solve problems such as loose contact of copper card slots, electric shock casualties, poor contact, etc., and achieve the effects of reducing the risk of electric shock, saving power, and reducing the number of times of plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

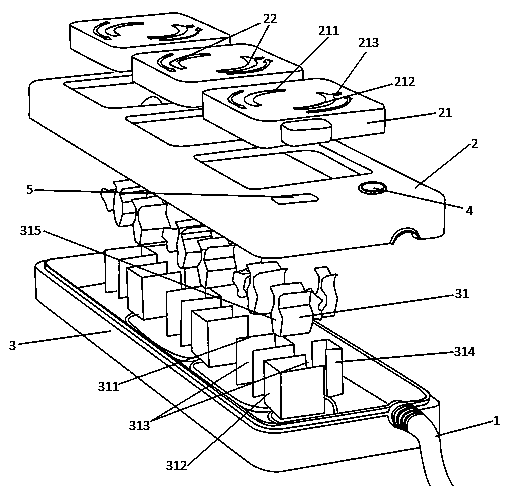

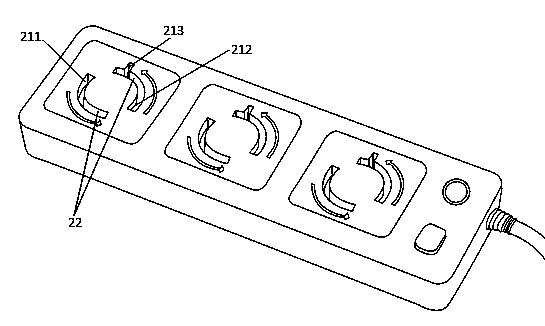

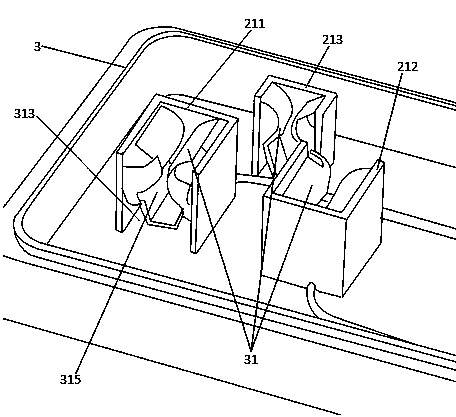

[0015] figure 1 It is a split diagram of a rotating safety plug-in strip; figure 2 It is a usage diagram of a rotary safety plug-in strip; image 3 It is a structural diagram of a rotary safety plug-in card slot. As shown in the figure, a rotary safety plug-in strip includes a wire 1, a top cover 2 and a bottom cover 3, the top cover 2 is provided with a panel 21, and the panel 21 is provided with a There are zero line socket 211 and live line socket 212, and the lower cover 3 of the plug-in row is respectively provided with a neutral line card slot 311 and a live line card slot 312 with a conductive copper sheet 31 which are symmetrical to the neutral line socket 211 and the live line socket 212. One side of the neutral wire socket 211 and the live wire socket 212 respectively extend in opposite directions to form a 30-90° arc-shaped groove 22, the arc-shaped groove 22 of the neutral wire socket and the arc-shaped groove 22 of the live wire socket share a circle center, an...

specific Embodiment 2

[0017] figure 1 It is a split diagram of a rotating safety plug-in strip; figure 2 It is a usage diagram of a rotary safety plug-in strip; image 3 It is a structural diagram of a rotary safety plug-in card slot. As shown in the figure, a rotary safety plug-in strip includes a wire 1, a top cover 2 and a bottom cover 3, the top cover 2 is provided with a panel 21, and the panel 21 is provided with a There are zero line socket 211 and live line socket 212, and the lower cover 3 of the plug-in row is respectively provided with a neutral line card slot 311 and a live line card slot 312 with a conductive copper sheet 31 which are symmetrical to the neutral line socket 211 and the live line socket 212. One side of the neutral wire socket 211 and the live wire socket 212 respectively extend in opposite directions to form a 30-90° arc-shaped groove 22, the arc-shaped groove 22 of the neutral wire socket and the arc-shaped groove 22 of the live wire socket share a circle center, an...

specific Embodiment 3

[0020] figure 1 It is a split diagram of a rotating safety plug-in strip; figure 2 It is a usage diagram of a rotary safety plug-in strip; image 3 It is a structural diagram of a rotary safety plug-in card slot. As shown in the figure, a rotary safety plug-in strip includes a wire 1, a top cover 2 and a bottom cover 3, the top cover 2 is provided with a panel 21, and the panel 21 is provided with a There are zero line socket 211 and live line socket 212, and the lower cover 3 of the plug-in row is respectively provided with a neutral line card slot 311 and a live line card slot 312 with a conductive copper sheet 31 which are symmetrical to the neutral line socket 211 and the live line socket 212. One side of the neutral wire socket 211 and the live wire socket 212 respectively extend in opposite directions to form a 30-90° arc-shaped groove 22, the arc-shaped groove 22 of the neutral wire socket and the arc-shaped groove 22 of the live wire socket share a circle center, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com