A heating fixture

A technology of fixing machine and heating head, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of unsightly products and the weak structure of the spirally pasted sponge on the side wall of the cylinder, so as to achieve tight fit and not easy to fall off. , The effect of product fit and tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

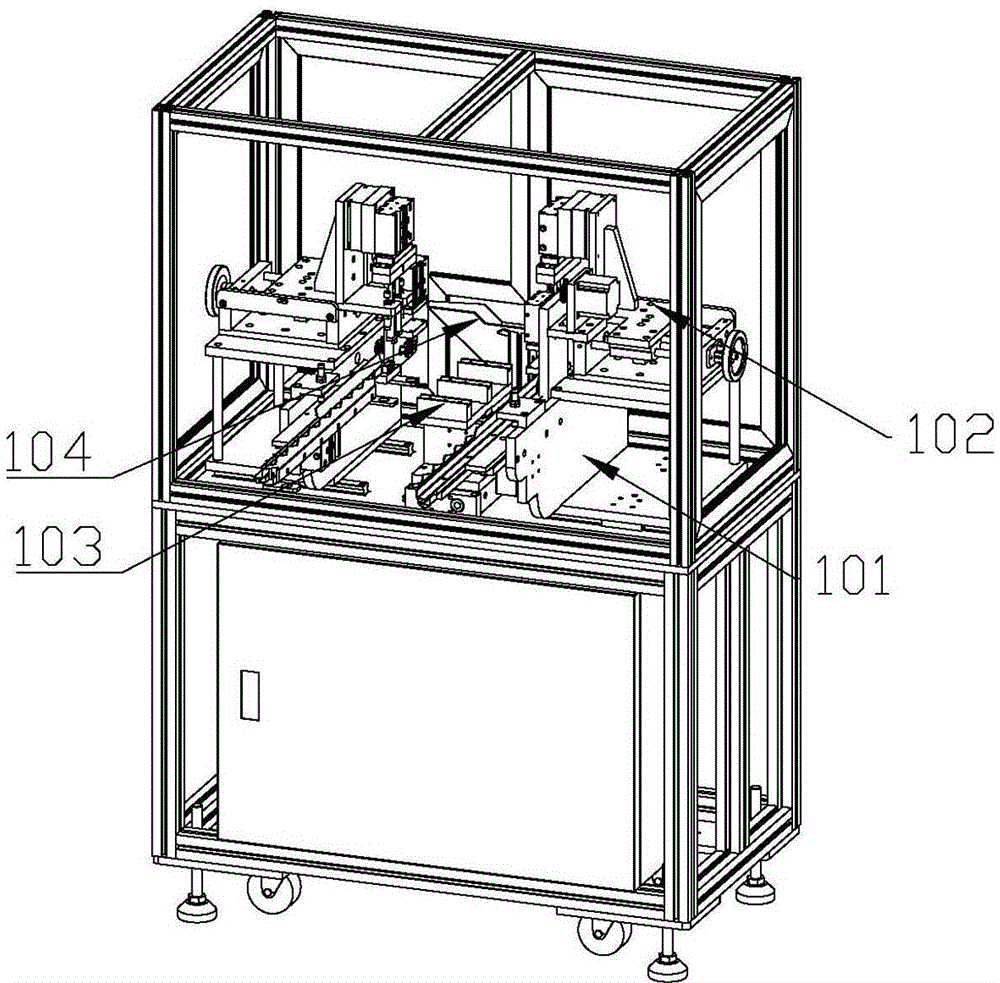

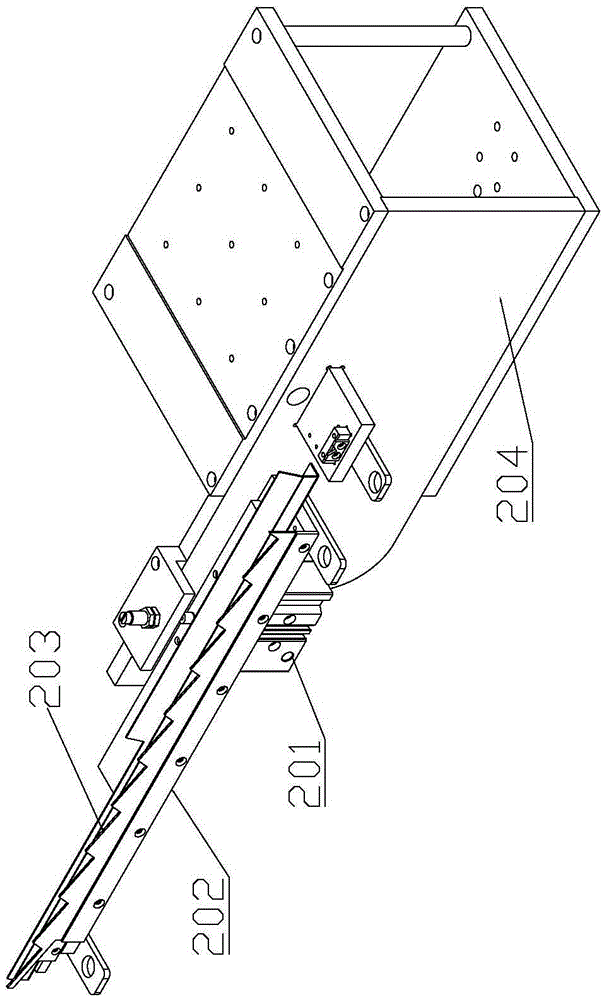

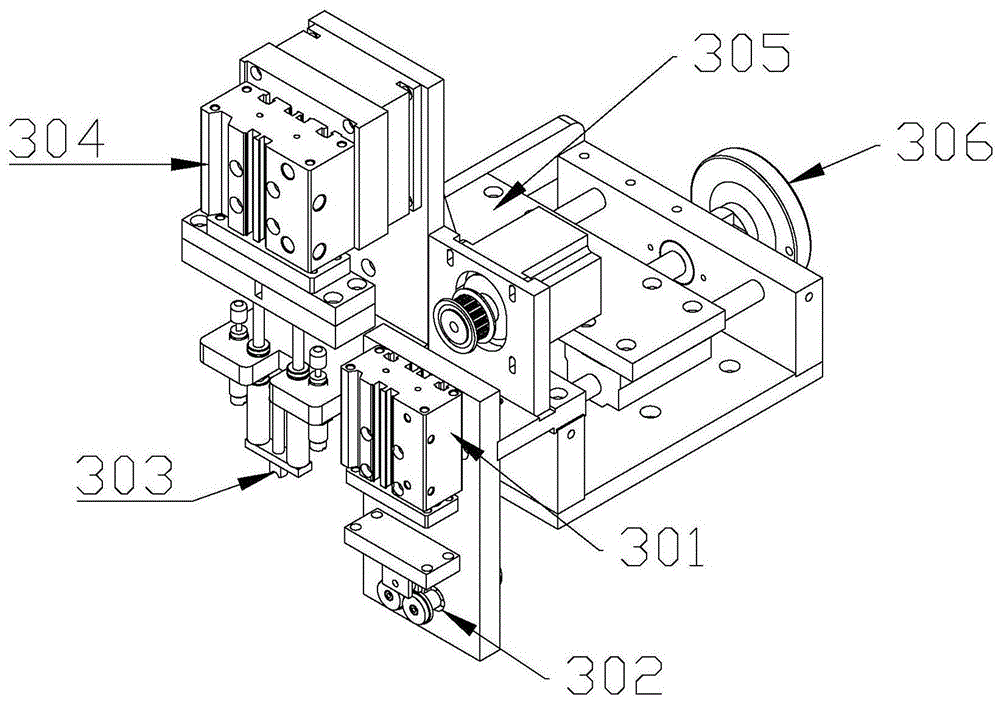

[0021] like figure 1 , 3 As shown, the technical solution adopted in the present invention is as follows: a heating and fixing machine, characterized in that: it includes a heating and fixing device 102, and the heating and fixing device 102 includes two oppositely arranged unilateral heating and fixing assemblies, and the unilateral heating and fixing assembly includes a heating head 303 and the rotating positioning roller 302; the heating head 303 and the rotating positioning roller 303 are arranged front and back along the material conveying direction, and the material is a rod wound around the sponge, and the heating head 303 heats one end of the sponge to fasten it with the rod; The first lifting device 304 is arranged on the head 303, and the first lifting device 304 drives the heating head 303 to move up and down; the rotating positioning roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com