Wheeled propeller

A propeller and propeller shaft technology, applied to propellers, wheels, vehicle parts, etc., can solve the problems of poor ground driving ability, poor passing performance, unsightly appearance, etc., and achieve the effect of protecting land resources and improving product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

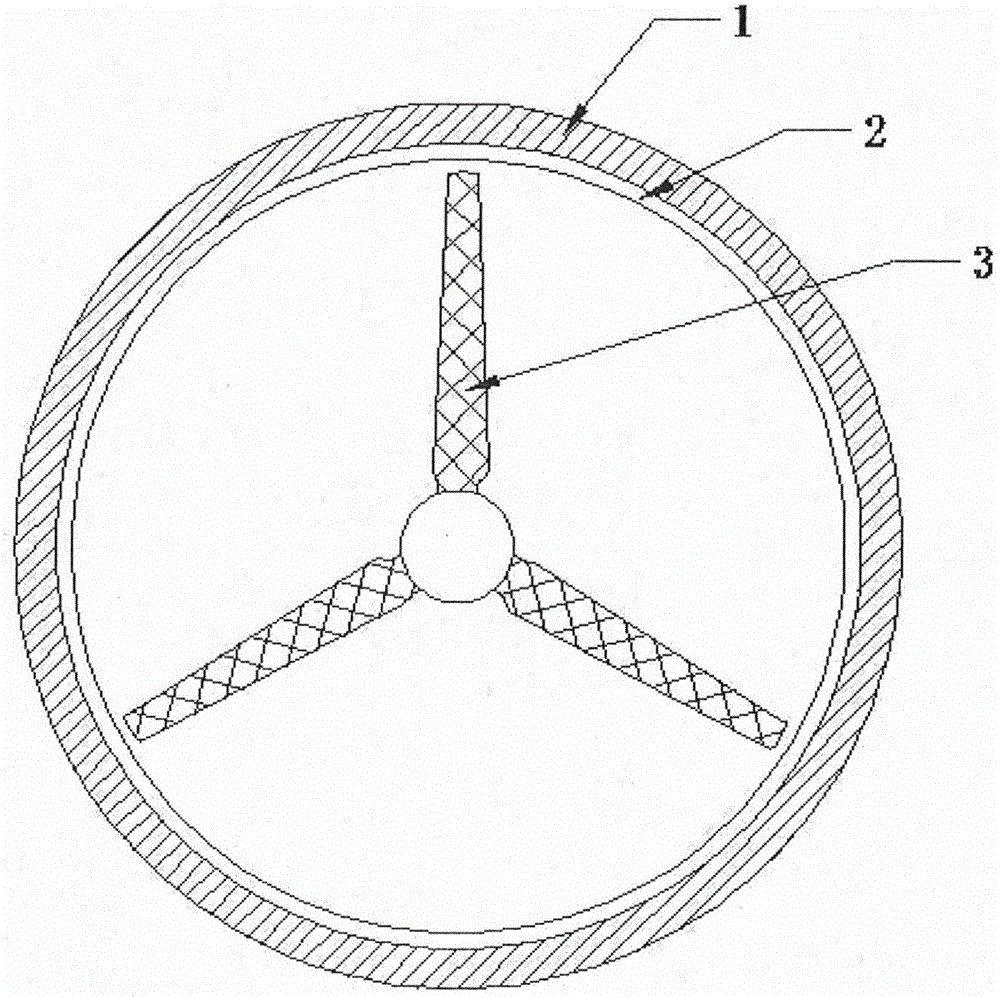

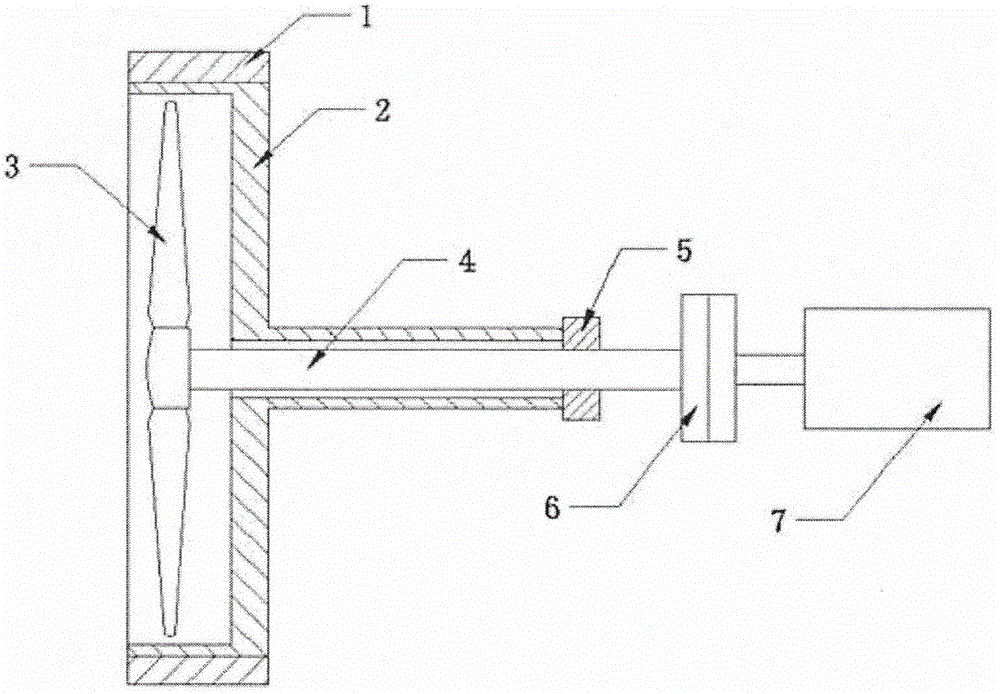

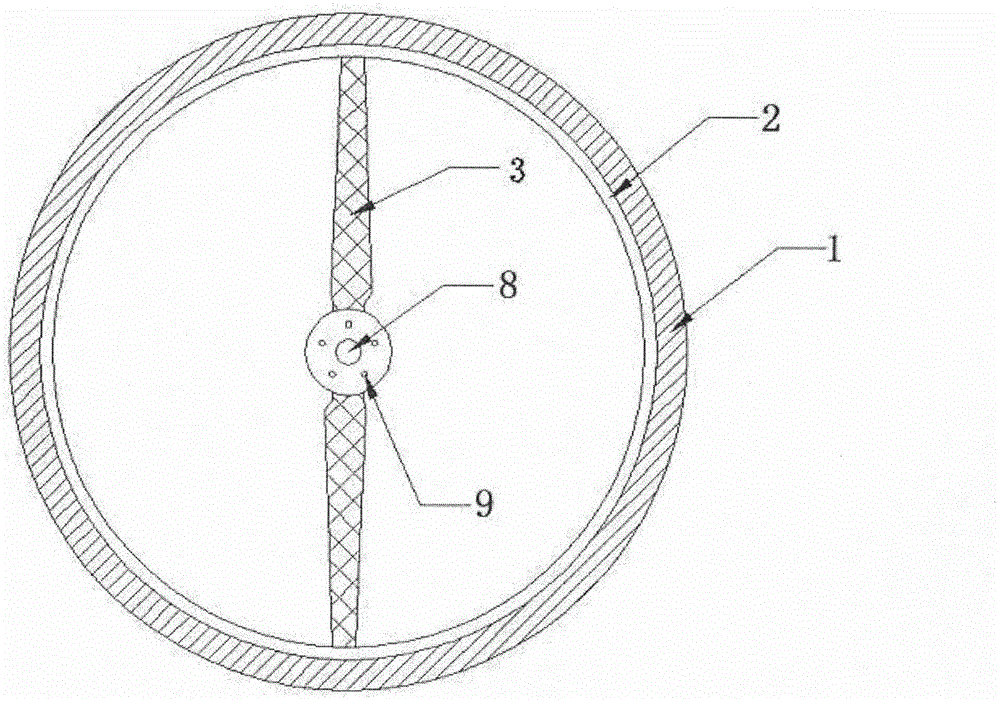

[0023] A wheel-type propeller of the present invention includes an inner support ring 2, an outer buffer tire 1 is arranged on the outside of the inner support ring 2, and several propeller blades 3 are arranged inside the inner support ring 2, and the propeller blades 3 pass through the propeller shaft 4. The shaft coupling 6 is connected with the engine 7 . The outer end of the propeller blade 3 can be fixedly connected with the inner support ring 2, or can be as figure 1 and figure 2 As shown, the outer end of the propeller blade 3 is separated from the inner support ring 2, and the inner support ring 2 is connected to the propeller shaft 4 through a clutch 5. Such as Figure 3-Figure 6 As shown, there can be 2, 3, 4 or more propeller blades 3, and the propeller blades 3 are evenly distributed inside the inner support ring 2. Such as Figure 7 and Figure 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com