Auxiliary lifting device for steam turbine high pressure valve assembly

A lifting device and high-pressure valve technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of heavy preparation work, insufficient clamping force, and unstable lifting process, so as to save time and secure the clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

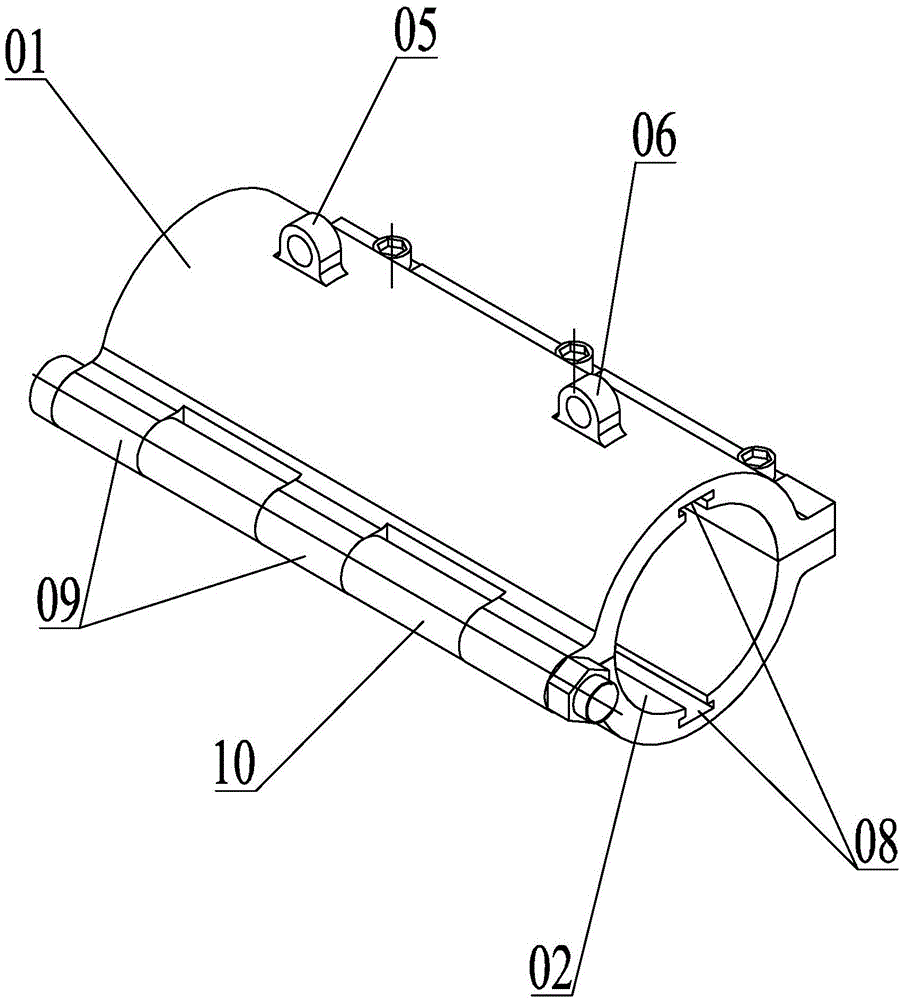

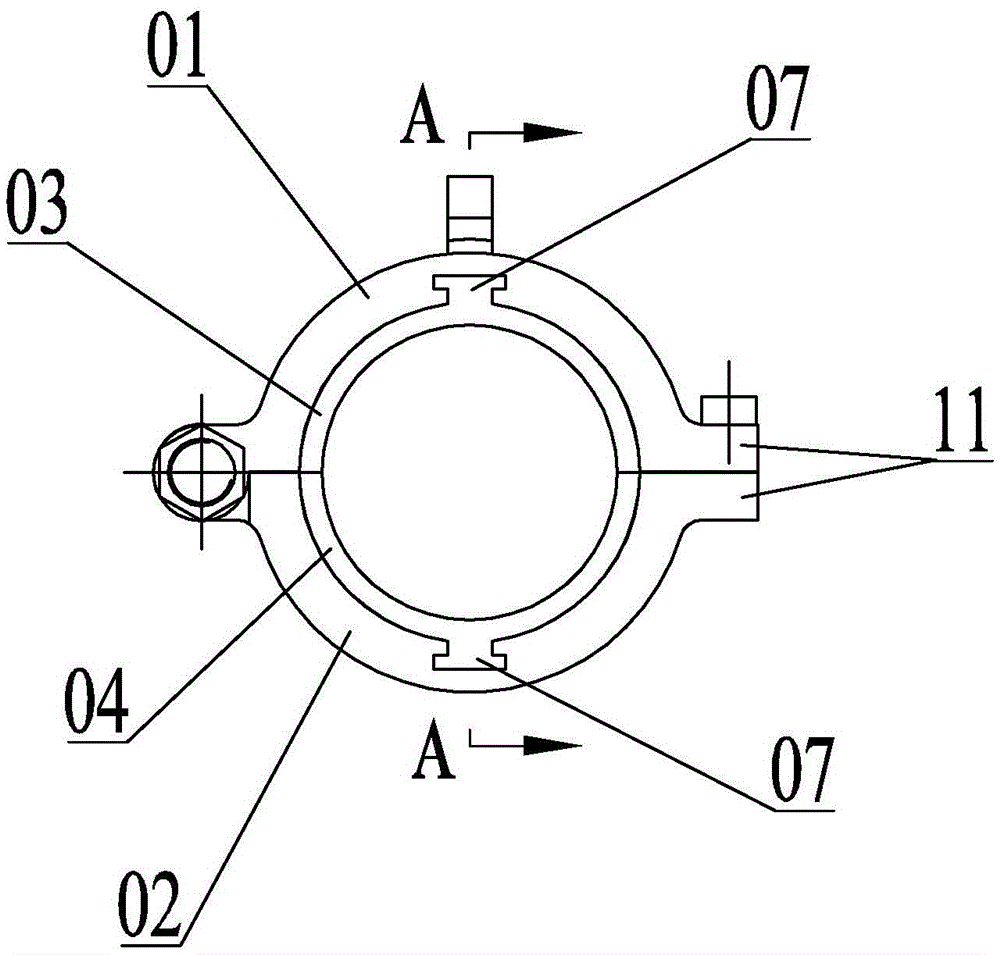

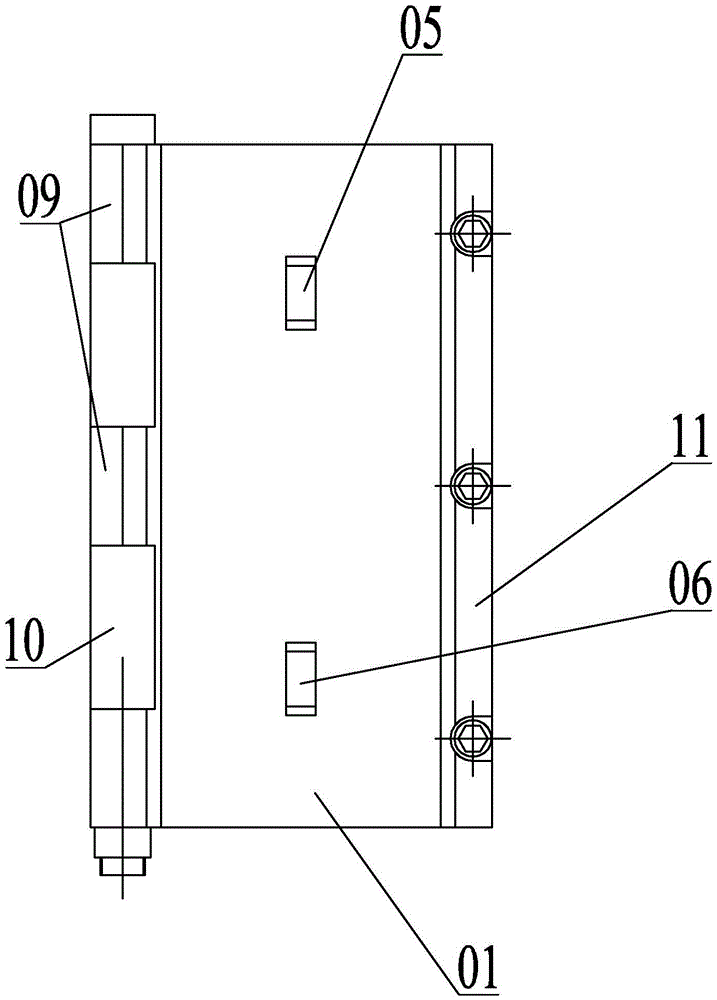

[0016] Specific implementation mode one: combine Figure 1 to Figure 6 Explain that the auxiliary lifting device for the assembly of the steam turbine high-pressure valve in this embodiment includes an upper casing 01, a lower casing 02, an upper lining tile 03, a lower lining tile 04, a lifting lug 05 and a lifting lug 2 06,

[0017] The cavity of the upper case 01 is opened on the bottom surface of the upper case 01 and penetrates the upper case 01 horizontally, and the cavity of the lower case 02 is opened on the top surface of the lower case 02 and penetrates the lower case 02 horizontally. The bottom surface of the shell 01 is attached to the top surface of the lower shell 02, the cavity of the upper shell 01 is set opposite to the cavity of the lower shell 02, the upper shell 01 is movably connected with the lower shell 02, and the upper lining tile 03 It is detachably fixed in the cavity of the upper casing 01, and the lower lining tile 04 is detachably fixed in the cav...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1 to Figure 6 Explain that the upper casing 01 and the lower casing 02 of this embodiment are both horizontally arranged cylinders with a semicircular cross-section, the horizontal surface of the upper casing 01 is the bottom surface, the horizontal surface of the lower casing 02 is the top surface, and the upper casing 02 is the top surface. The shape of the tile 03 is consistent with the shape of the upper casing 01, and the shape of the lower lining tile 04 is consistent with that of the lower casing 02.

[0020] The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 1 to Figure 6 Explain that the outer arc surface of the upper lining tile 03 and the outer arc surface of the lower lining tile 04 in this embodiment are fixed with T-shaped keys 07, the inner arc surface of the upper casing 01 and the inner circle of the lower casing 02 There are T-shaped grooves 08 on the arc surface, the T-shaped key 07 of the upper lining tile 03 is matched with the T-shaped groove 08 of the upper shell 01, and the T-shaped key 07 of the lower lining tile 04 is matched with the T-shaped groove of the lower shell 02. 08, the T-shaped slot 08 is set on one end surface of the upper shell 01 and is not penetrated along the axis of the upper shell 01, and the T-shaped slot 08 is set on one end surface of the lower shell 02 and is not penetrated along the axis of the lower shell 02 open.

[0022] In this embodiment, the T-shaped groove 08 is not opened through, so that the positioning of the T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com