A method for making freehand brushwork twisted tire purple sand mud

A production method and technology of purple sand mud, applied in the field of twisted tire mud production and twisted tire purple sand mud production, can solve the problems of poor ornamental value, inability to form patterns, single and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: a kind of freehand drawing twist tire purple sand mud making method is characterized in that comprising the following steps:

[0011] a. Mixing mud: Divide the mud into A, B, and C three kinds of ratios. The components of the A mud are mass percentage: 40# old purple mud 50%, 30# bottom tank 30%, 60# day Blue 5%%, water 15%; Its component of described B mud material is mass percentage: 40# Hongpilong 60%, 40# middle tank 20%, water 20%; Its component of described C mud material is mass percentage Percentage: 90% of 40# descending slope mud, 5% of 40# Benshan recorded mud, 5% of water, dry the above three kinds of mud for later use;

[0012] b. Preparation of twisted tire mud: beat A into 0.5mm~1mm thick slices, and then beat B into 1mm, 1.5mm, 2mm thick slices according to the needs of the screen; Different kinds of mud are superimposed layer by layer, sprayed with water to keep the mud moist, and 30 to 50 layers are stacked to make AB mixed mud, which is...

Embodiment 2~6

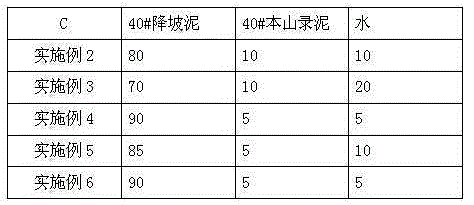

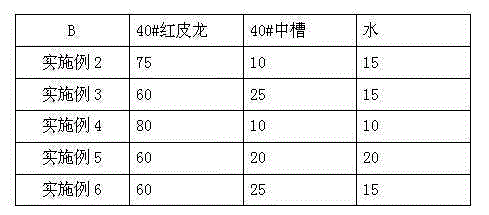

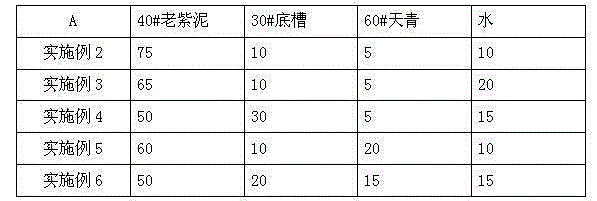

[0014] Embodiment 2~6, with reference to embodiment 1, change the proportioning parameter of A, B, C raw material, as shown in the table below:

[0015]

[0016]

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com