Ultra-pressure sintered dense solid knife from polycrystalline integrated cubic boron nitride and production method thereof

A cubic boron nitride and ultra-high pressure technology, applied in the field of improved material cutting tools and their manufacturing, can solve problems such as shortened service life, damage to the coating film, peeling of the coating film, etc., to prevent cracks and overcome easy wear and tear. , good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

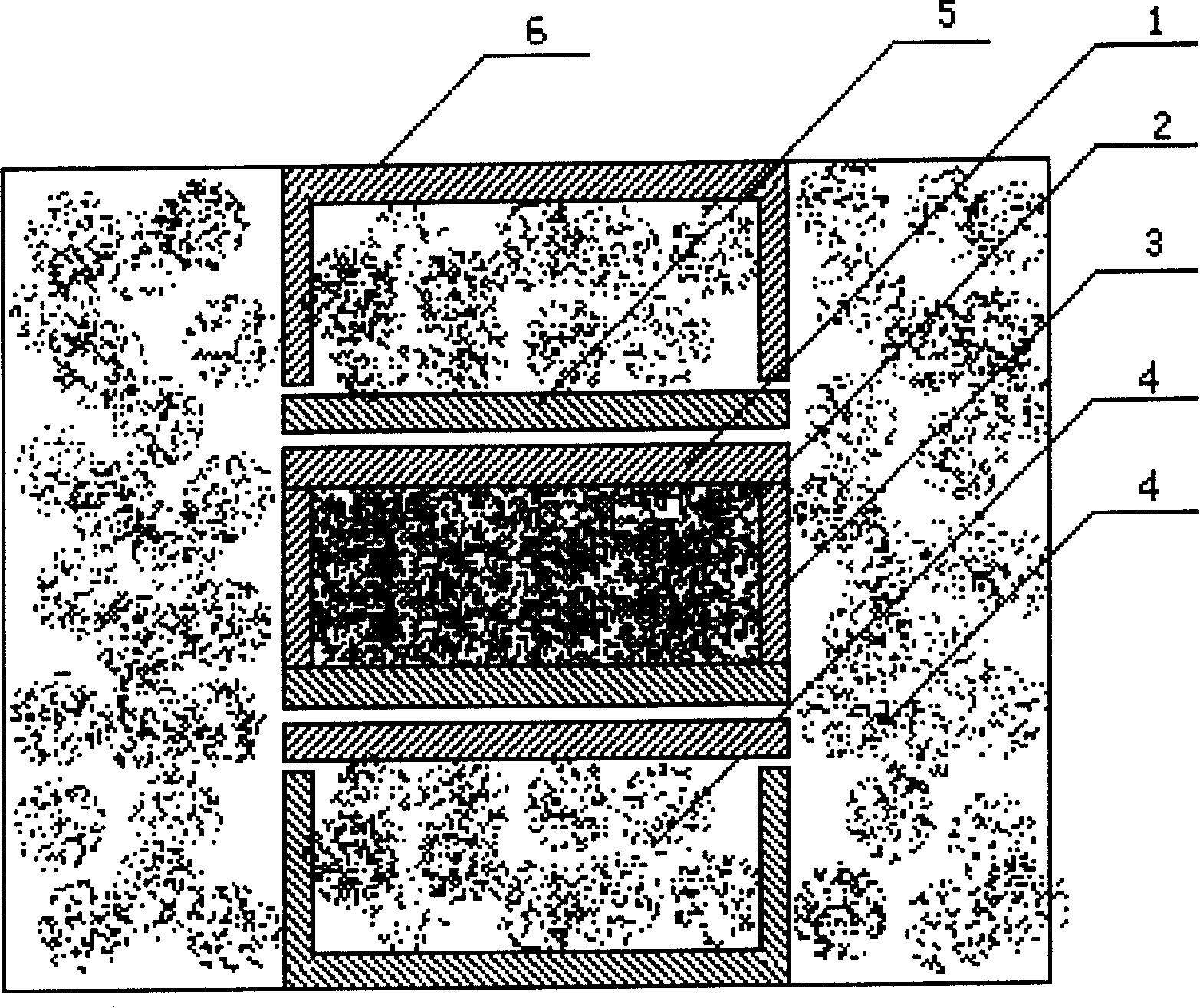

Image

Examples

Embodiment Construction

[0019] Material formula 1: 75% by weight of polycrystalline cubic boron nitride fine powder, 15% by weight of cobalt aluminum alloy fine powder, and 10% by weight of ceramic fine powder additive.

[0020] Material formula 2: 85% by weight of polycrystalline cubic boron nitride fine powder, 10% by weight of cobalt aluminum alloy fine powder, and 5% by weight of ceramic fine powder additive.

[0021] Material formula 3: 80% by weight of polycrystalline cubic boron nitride fine powder, 12% by weight of cobalt aluminum alloy fine powder, and 8% by weight of ceramic fine powder additive.

[0022] The above micropowder:

[0023] (1) In the cobalt-aluminum alloy micropowder, cobalt accounts for 2% by weight, and aluminum accounts for 98% by weight; TiC accounts for 3% by weight in the ceramic micropowder additive, Al O accounts for 10% by weight, TiN accounts for 30% by weight, and AlB accounts for 57% by weight.

[0024] (2) In the cobalt-aluminum alloy micropowder, cobalt accounts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com