Flexible joint bearing structure

A flexible joint and bearing technology, applied in the field of flexible joint bearing structure, can solve problems such as bearing damage, easy wear, and reduced bearing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

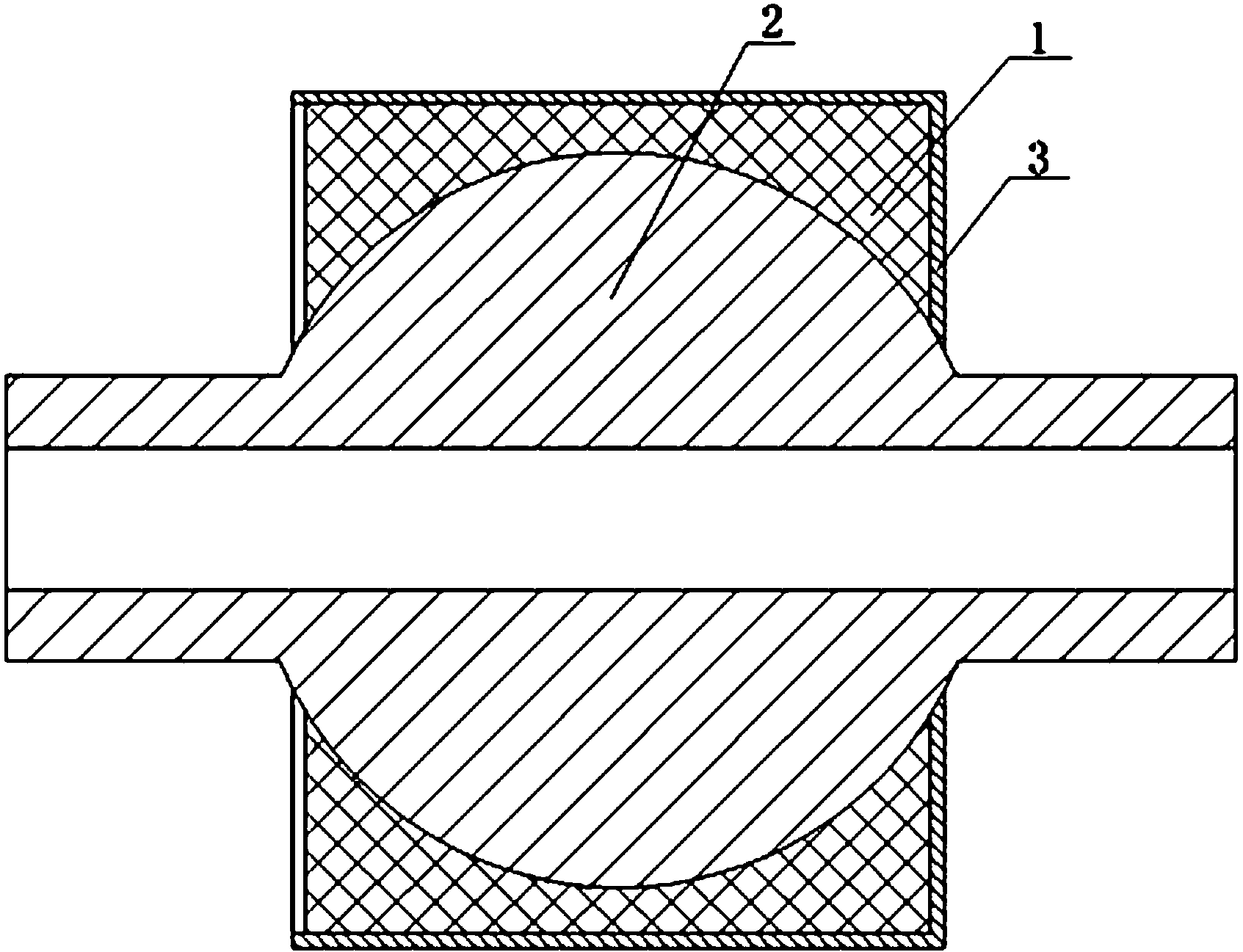

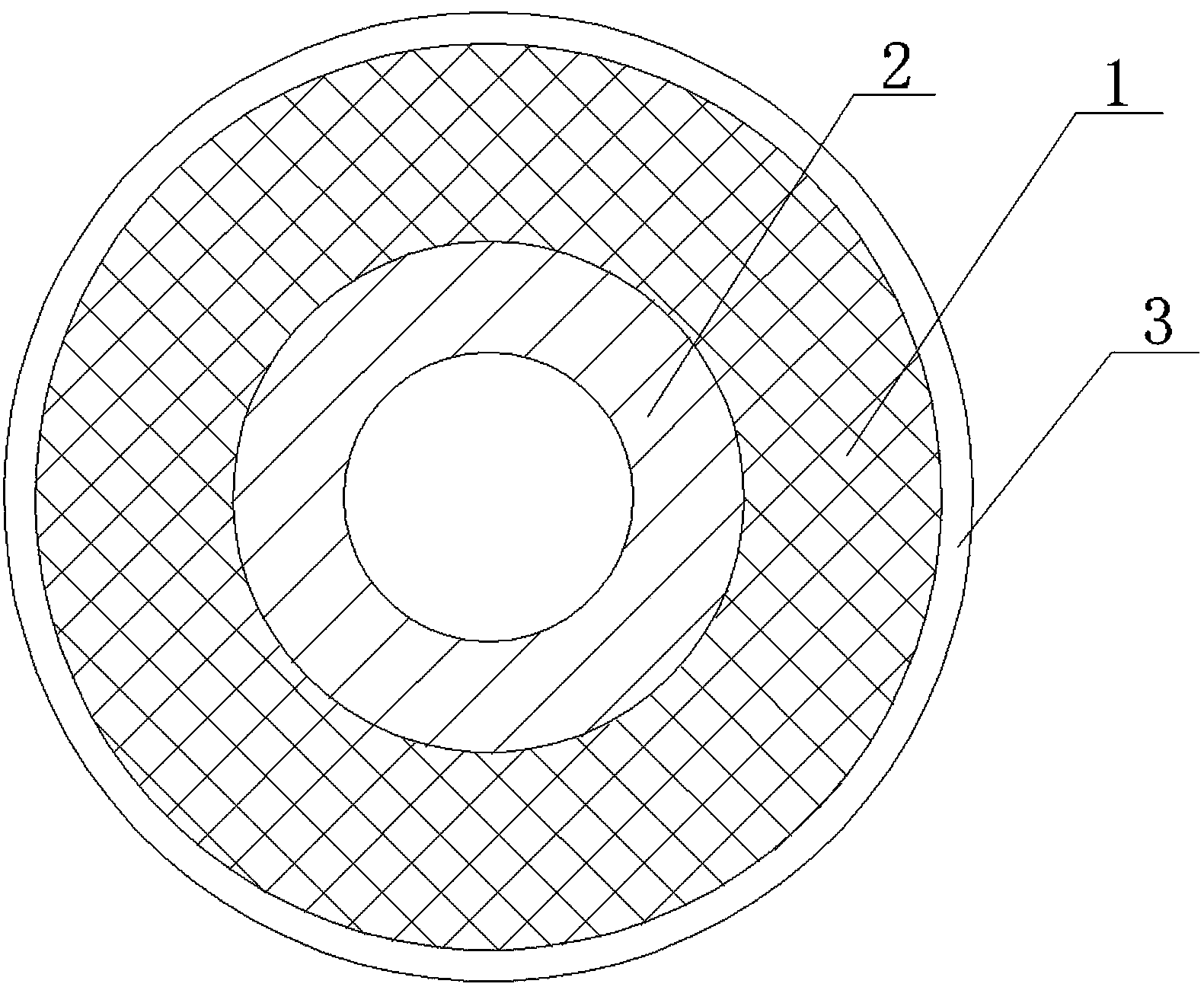

[0009] See figure 1 , figure 2 , a flexible joint bearing structure, including an outer ring 1 and an inner ring 2, the outer ring 1 is arranged in the housing 3, the outer ring 1 is made of a flexible material, and the outer ring 1 and the housing are in interference fit. Since the outer ring is made of a flexible material, The interference fit between the outer ring and the shell effectively ensures the flexible contact between the outer ring and the shell when the joint bearing is mechanically connected, effectively avoiding the bearing damage caused by the easy wear of the bearing during use, and improving the bearing performance. service life, thereby reducing production costs.

[0010] Ordinary joint bearings can only realize the flexibility of the bearing's rotation direction, and the radial and axial directions are both rigid. However, the flexible joint bearing structure of the present invention realizes the radial, axial and rotational direction of the joint bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com