Cylindrical gear tooth backlash adjusting device with bend screw

A tooth backlash and cylindrical gear technology, which is applied to belts/chains/gears, transmission parts, components with teeth, etc., can solve the problems of uneven and continuous rotation, operator inconvenience, and uncontrollable backlash size, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

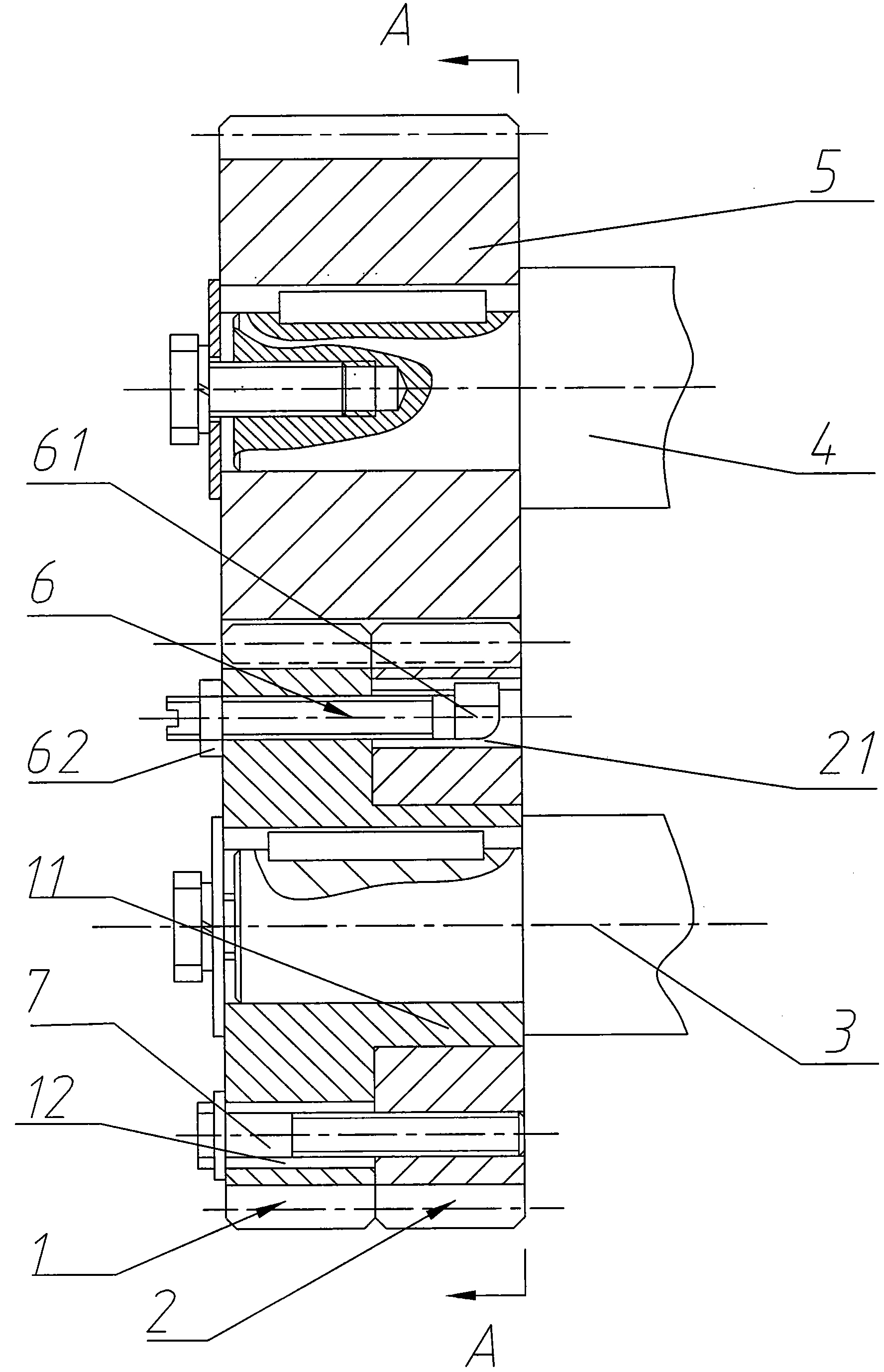

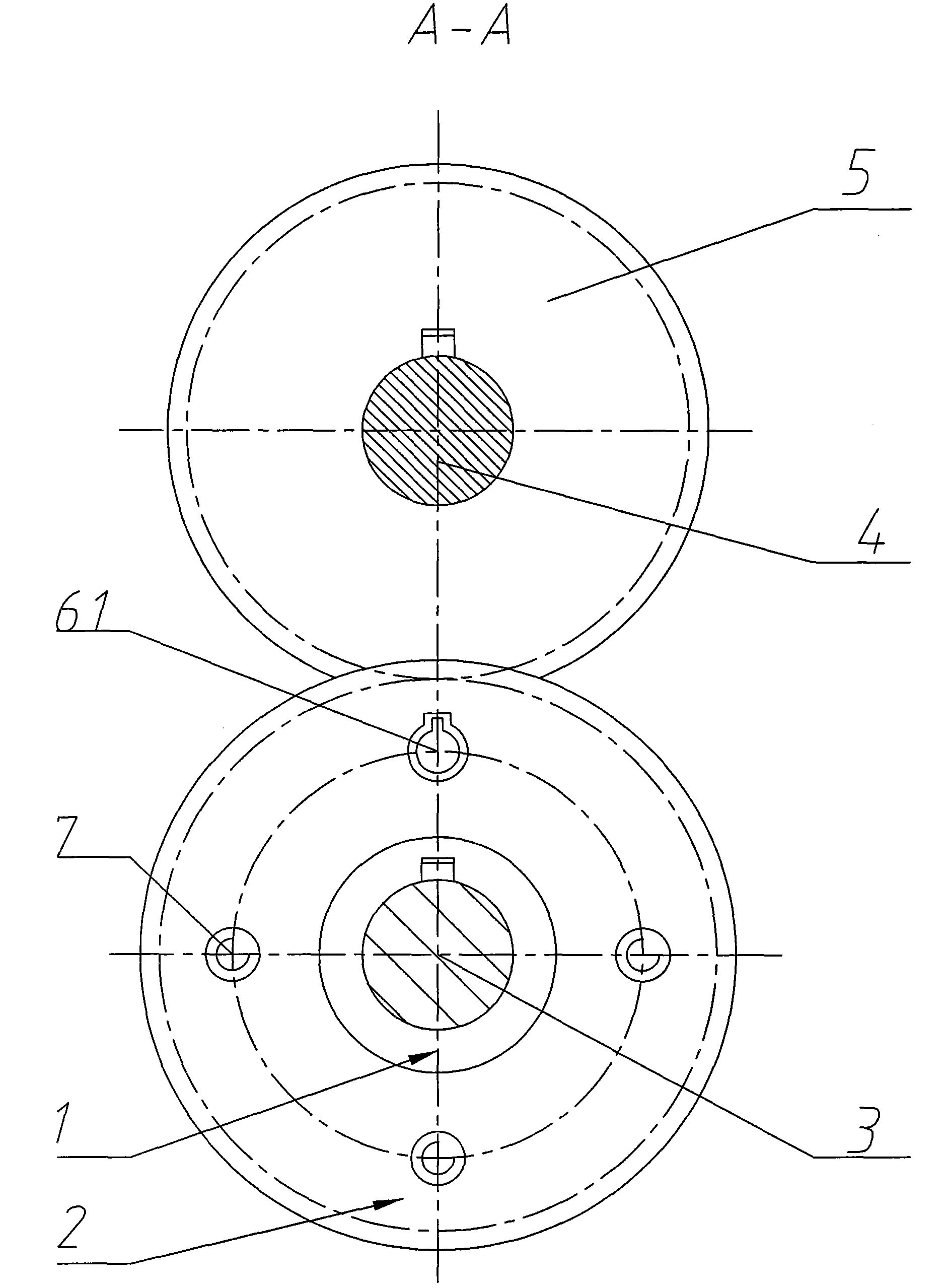

[0014] Such as figure 1 , 2 Shown is a device with an elbow screw to adjust the side clearance of cylindrical gears, which includes two meshing gear pairs. The two meshing gear pairs are described, and one of the meshing gears is composed of a fixed gear 1 and an adjustable The fixed gear 1 is composed of gear 2, and the center hole of the fixed gear 1 is provided with an axial keyway corresponding to the keyway on the first transmission shaft 3, which is connected and fixed on the journal of the first transmission shaft 3 with a flat key, and the other meshing gear is integral The central hole of the gear 5 is provided with an axial keyway corresponding to the keyway on the second transmission shaft 4, and is connected and fixed on the journal of the second transmission shaft 4 with a flat key. One end surface of the fixed gear 1 is integrally formed with a circle Ring boss 11, the adjustable gear 2 is provided with an inner hole that matches the ring boss 11 of the fixed ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com