Method for rapidly detecting fatigue resistance of mechanical watch spring

A technology of fatigue resistance and mechanical watch, which is applied in the field of rapid detection of fatigue resistance of mechanical watch springs, which can solve problems such as insufficient professional and reliable experimental data, inability to meet the wear conditions of various systems of the movement, and lack of regularity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

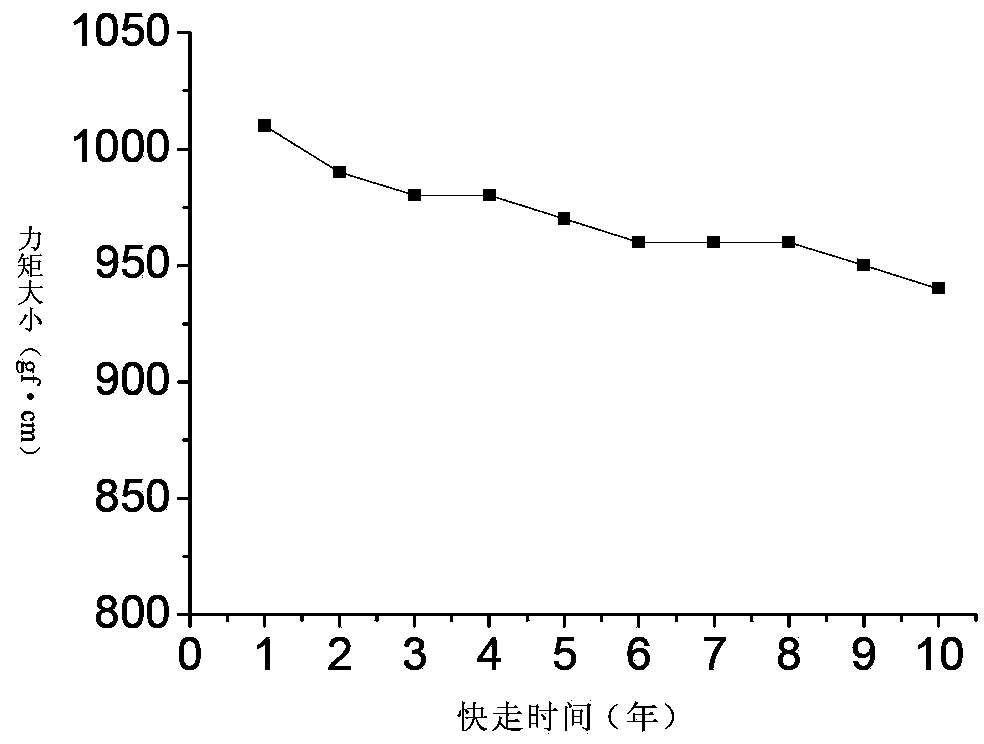

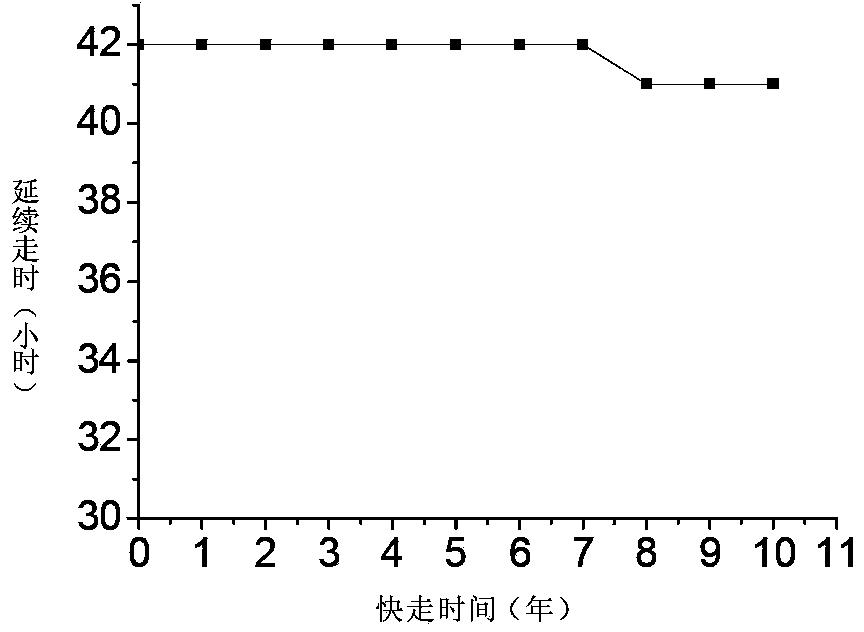

[0043] In this embodiment, a method for quickly detecting the fatigue resistance of a mechanical watch spring comprises the following steps:

[0044] 1) Before the test, perform a performance test on the movement. The test item is the continuation of the movement time of the movement. The movement is fully loaded and compared with the standard timepiece. Record the start time of the movement at this time, which is March. At 15 o'clock in the afternoon on the 15th, place the movement still, without any vibration or shaking, and carry out the actual movement on the surface. When the movement stops, compare it with the standard timepiece and record the stop time at this time. It is at 9 o'clock in the morning on March 17th, calculate the time difference before and after, and get the continuous travel time data T of the movement 0 for 42 hours.

[0045] 2) In step 1), the meaning of continuation of travel time is: when the mainspring is fully wound and fully relaxed, the stored e...

Embodiment 2

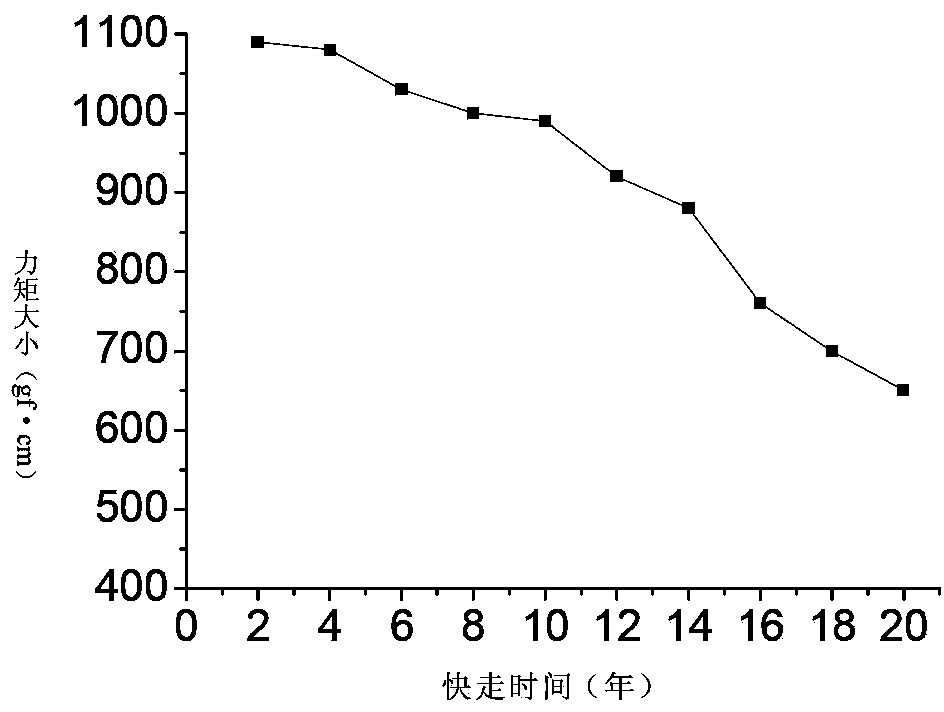

[0057] In this embodiment: a method for quickly detecting the fatigue resistance of a mechanical watch clockwork, comprising the following steps:

[0058] 1) Before the test, conduct a performance test on the movement. The test item is the continuation of the movement time of the movement. The movement is fully loaded and compared with the standard timepiece. Record the start time of the movement at this time, which is April. At 15:00 p.m. on the 3rd, place the movement still, without any vibration or shaking, and carry out the real movement of the position on the surface. When the movement stops, compare it with the standard timepiece and record the stop time at this time. It is 12 o'clock in the morning of April 05th, calculate the time difference before and after, and get the continuous travel time data T of the movement 0 for 45 hours.

[0059] 2) In step 1), the meaning of continuous travel time is: when the mainspring is fully wound and fully relaxed, the stored energy ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap