A design method of anti-glare LED lamp

A technology of LED lamps and design methods, applied in semiconductor devices of light-emitting elements, light sources, lighting and heating equipment, etc., can solve the problems of unfavorable installation of the whole lamp, high cost and large size of the extinction grid 6, and achieve the anti-glare range Large, versatile, low-impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

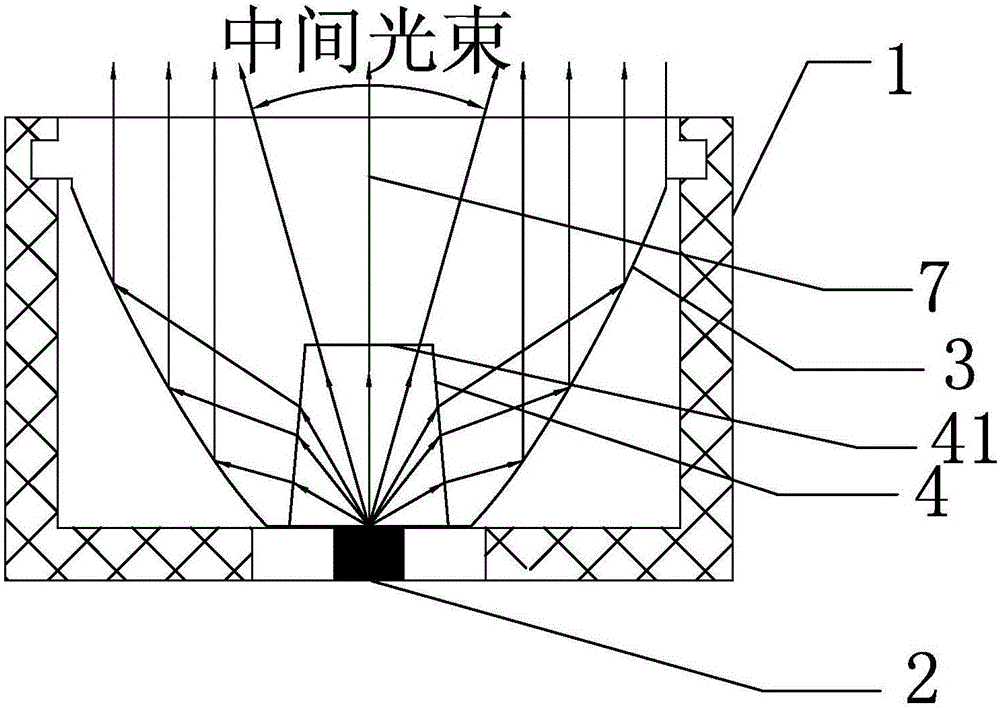

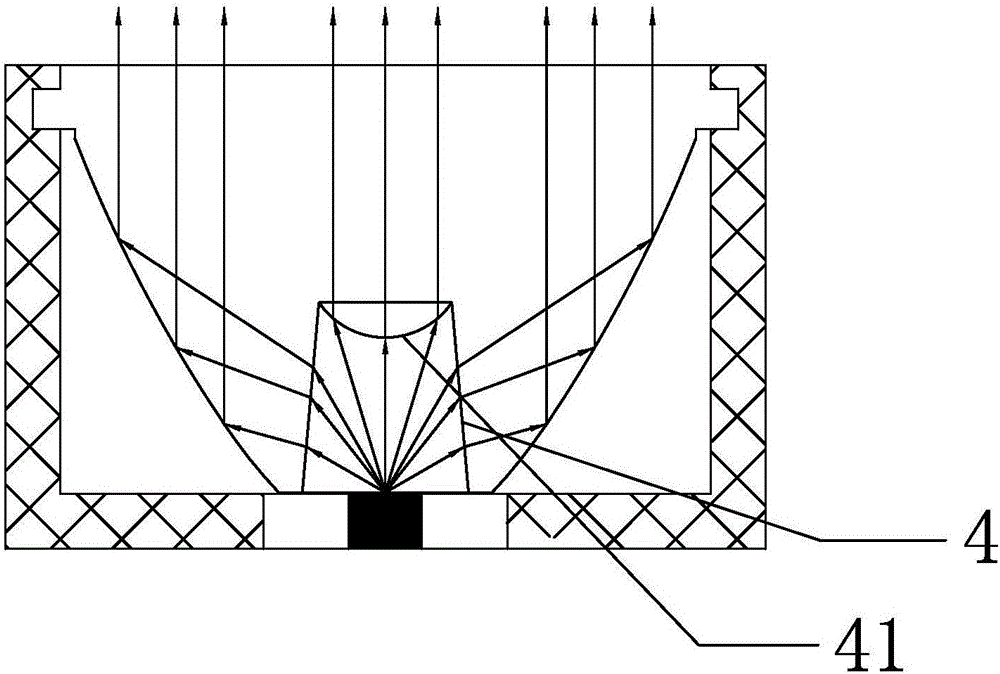

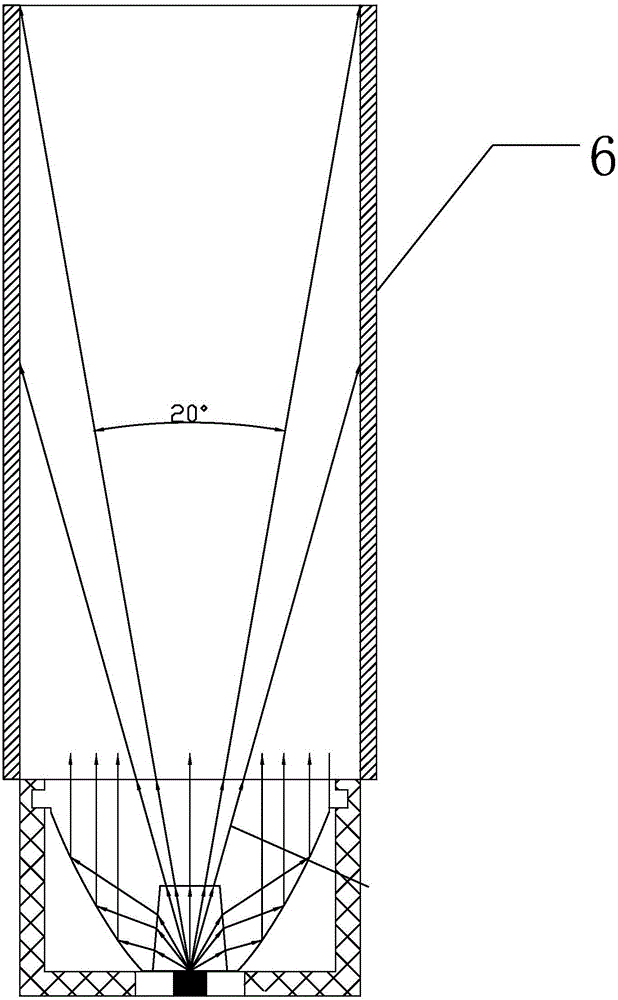

[0037] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

[0038] Such as Figure 4 As shown, an anti-glare LED lamp in this embodiment includes an LED light source 61, a lens 62 and a bracket 6, the top surface 623 of the lens 62 is a light-emitting surface, and the side surface 622 of the lens 62 is a total reflection surface or a reflection surface. A sunken groove 621 is provided on the bottom surface of the lens 62. The sunken groove 621 has an incident side surface 624 and an incident top surface 625 that allow light to enter the lens 62. The LED light source 61 is at the center of the notch of the sunken groove 621. The incident top surface 625 of 621 is fixed with a matting insert 5, and the position where the plane where the bottom surface 51 of the matting insert 5 is located and the incident side 624 intersects is just the incident point 8 of the outermost light path of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com