Epoxy resin composition, cured product thereof, and curable resin composition

A technology of curable resin and epoxy resin, applied in the field of curable resin composition, can solve problems such as reduced visibility, and achieve the effects of less birefringence, excellent heat resistance and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0196] Hereinafter, the present invention will be described in more detail through synthesis examples and examples. In addition, this invention is not limited to these synthesis examples and Examples. In addition, each physical property value in an Example was measured by the following method.

[0197] Various analysis methods used in Examples are described below.

[0198] Epoxy equivalent: According to JIS K 7236 (ISO 3001)

[0199] ICI Melt Viscosity: According to JIS K 7117-2 (ISO 3219)

[0200] Softening point: According to JIS K 7234

[0201] Total chlorine: According to JIS K 7243-3 (ISO 21672-3)

[0202] Chloride ion: According to JIS K 7243-1 (ISO 21672-1)

[0203] Sodium ions: determined by ion chromatography

[0204] Iron content: ICP spectroscopic analysis

[0205] Refractive index: According to ISO 5661

[0206] Gardner color number: according to ISO 4630-1

[0207] GPC:

[0208] Chromatographic column (Shodex KF-603, KF-602×2, KF-601×2)

[0209] Combine...

Synthetic example 1

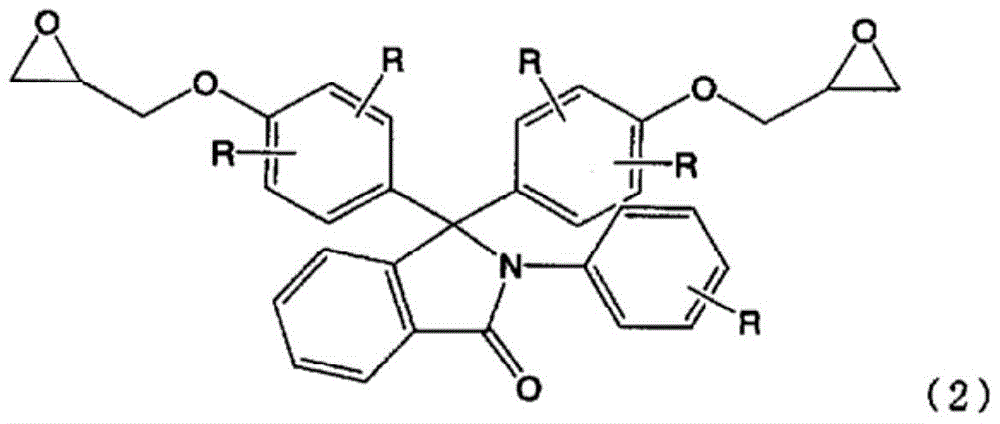

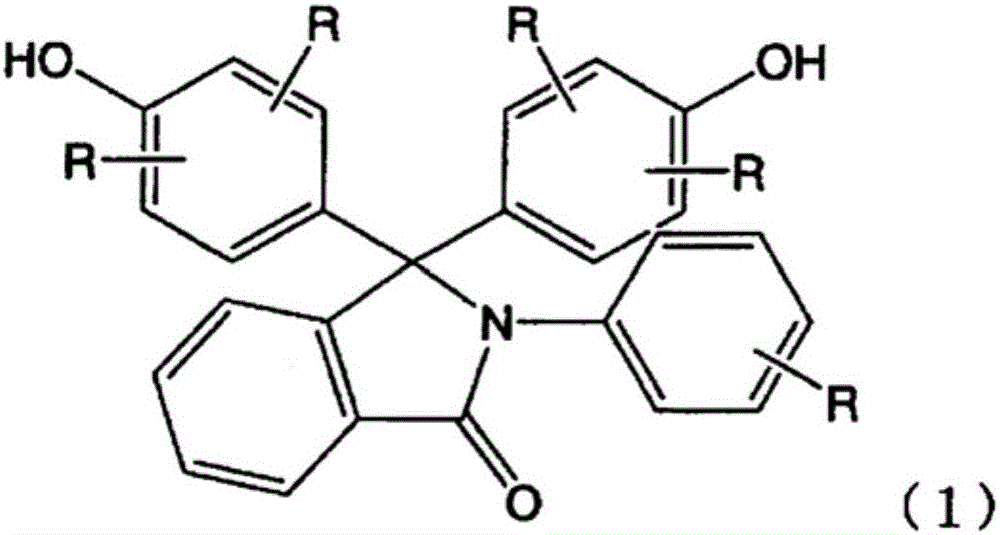

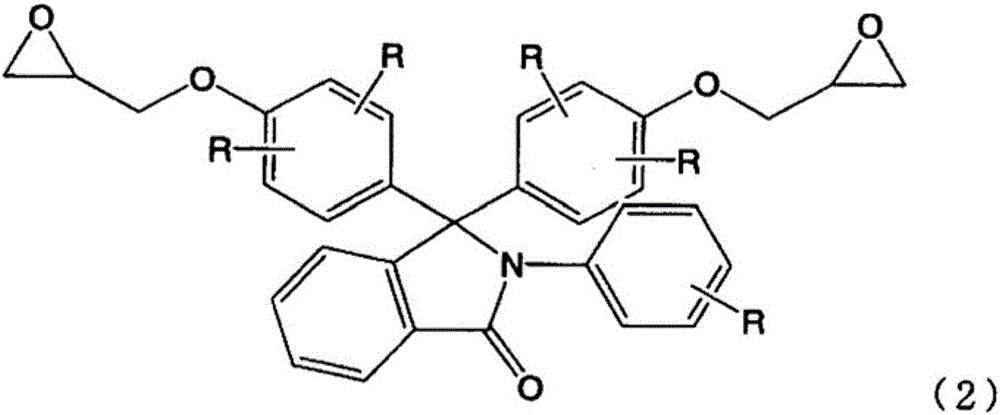

[0214]The flask equipped with a stirrer, a reflux condenser, and a stirring device was first vacuumed, and after nitrogen replacement, while implementing a nitrogen purge (2L / hour), add a phenolic compound (DPPI1) (the substituent in the above formula (1) R is a compound of hydrogen atoms, SABIC PPPBP, the purity is more than 99%, the residual phenolphthalein is 200ppm, iron content <5ppm) 255 parts, epichlorohydrin 842 parts, methanol 168 parts, the water bath is heated to 75 ℃. When the internal temperature exceeded 65° C., after adding 21 parts of flaky sodium hydroxide in batches over 90 minutes, a post-reaction was further performed at 70° C. for 1 hour. After completion of the reaction, water washing was performed, and solvents such as excess epichlorohydrin were distilled off from the oil layer at 140° C. under reduced pressure using a rotary evaporator. To the residue, 200 parts of methyl isobutyl ketone was added and dissolved, and the temperature was raised to 70°C. ...

Synthetic example 2

[0216] In a 1L flask equipped with a stirrer, a reflux condenser, and a stirring device, while purging nitrogen (2L / hour), add a phenolic compound (DPPI1) (the substituent R in the above formula (1) is a hydrogen atom The compound, SABIC PPPBP, has a purity of more than 99%, residual phenolphthalein is 200ppm, iron content <5ppm) 255 parts, epichlorohydrin 601 parts, methanol 180 parts, and the water bath is heated to 75°C. After 1.5 hours (approximately 3 times the amount of nitrogen blown into the flask) after the start of the nitrogen purge, and further confirming that the internal temperature exceeded 65° C., 21 parts of flaky sodium hydroxide were added in batches over 90 minutes. Then, a post-reaction was further performed at 70° C. for 1 hour. After completion of the reaction, water washing was performed, and solvents such as excess epichlorohydrin were distilled off from the oil layer at 140° C. under reduced pressure using a rotary evaporator. To the residue, 200 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com