Rolling device for boss ring of exhaust pipe nozzle of rail engineering vehicle

The technology of a rail engineering vehicle and a rolling device is applied in the field of processing and manufacturing a boss ring for the nozzle connection of the intake and exhaust pipes of the rail engineering vehicle, which can solve the problems of large investment and high cost of the nozzle connection boss ring equipment, and achieves Low manufacturing cost, reasonable structure, and satisfying the effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure of the present invention is described with reference to the examples given in the accompanying drawings.

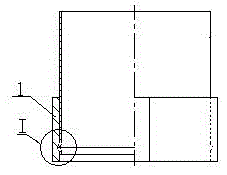

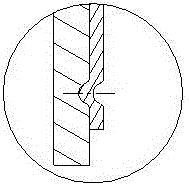

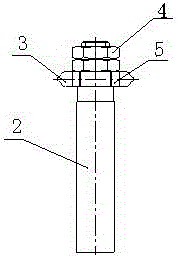

[0017] Such as figure 1 , figure 2 , image 3 Shown: a rolling device for the boss ring of the exhaust pipe nozzle of a rail engineering vehicle, the rolling device includes a rolling assembly and a clamp 1; Figure 4 , Figure 5 , the clamp 1 is an open ring with an opening in the axial direction; the clamp 1 is cut and processed from a 45# round steel pipe, and is a basic part for fixing the workpiece in this set of tooling; the clamp The hoop 1 is set on the exhaust pipe of the required rolling boss ring to prevent the deformation of the round pipe when making the boss ring; The concave ring matched with the boss ring of the pipe; the rolling assembly includes a rolling knife rod 2, a rolling knife sleeve 5 and a rolling knife 3; Figure 6 , the rolling knife bar 2 is processed from keyway steel or round bar stock, and is the basic part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com