Mid-through type steel box basket arch segment lifting device

A hoisting device and arch segment technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problem of short construction period of mid-support steel box basket arch bridges, difficult to ensure accurate positioning of hoisting segments, and difficult to control the manufacturing line. and other problems to achieve the effect of improving production efficiency, solving hoisting angle positioning, and reducing manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

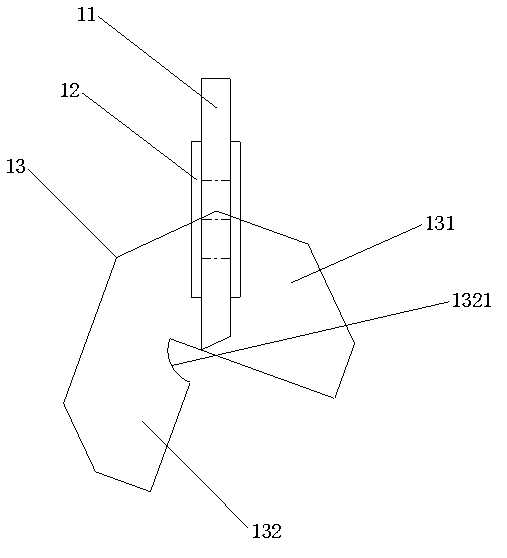

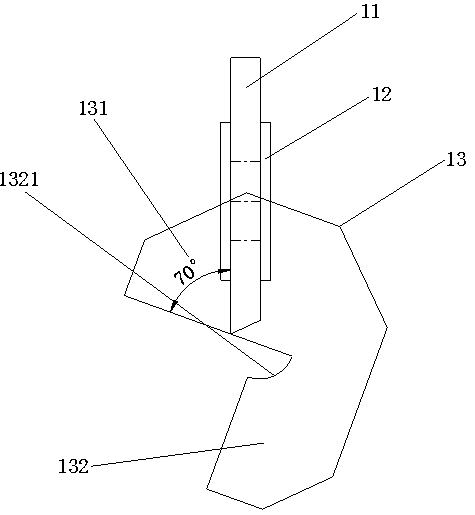

[0035] ① Assemble and weld two pairs of first hoisting assemblies 1 of the present invention on both sides of the top plate and web of the hoisting section 3 respectively, and assemble and weld the other pair of second hoisting assemblies 2 on the end of the outer web near the edge of the bottom plate;

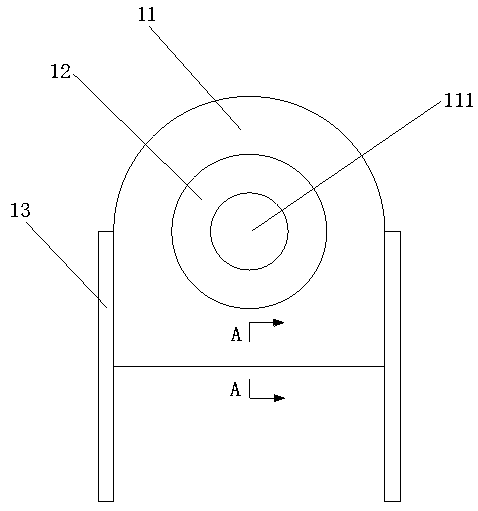

[0036] ② Pass the auxiliary steel rope through the first hoisting hole 111 of the first lug piece 11 and the second hoisting hole 211 of the second lug piece 21, and hang it on the hook of the lifting device;

[0037] ③ Start the hoisting equipment to lift the hoisting section, adjust the angle of the steel rope, and start the bridge position welding operation after the hoisting section is measured and positioned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com