Corner bending device for disc spring

A disc-shaped spring and angle-bent technology, which is applied in the direction of manufacturing springs from wires, other household appliances, household appliances, etc., can solve the problems of affecting installation, insufficient spring precision, scrapping and remanufacturing, etc., to ensure the processing size and meet the production accuracy , Improve production efficiency and the effect of qualified product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

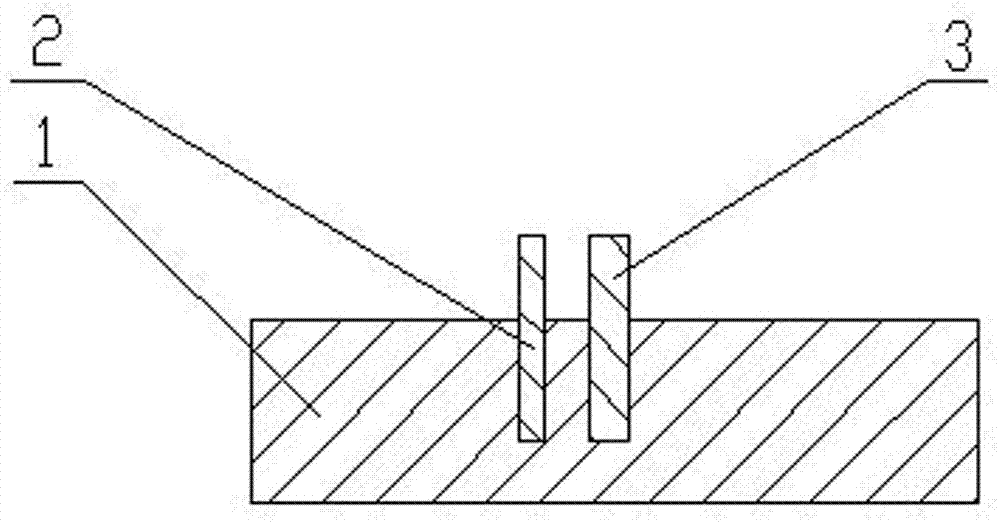

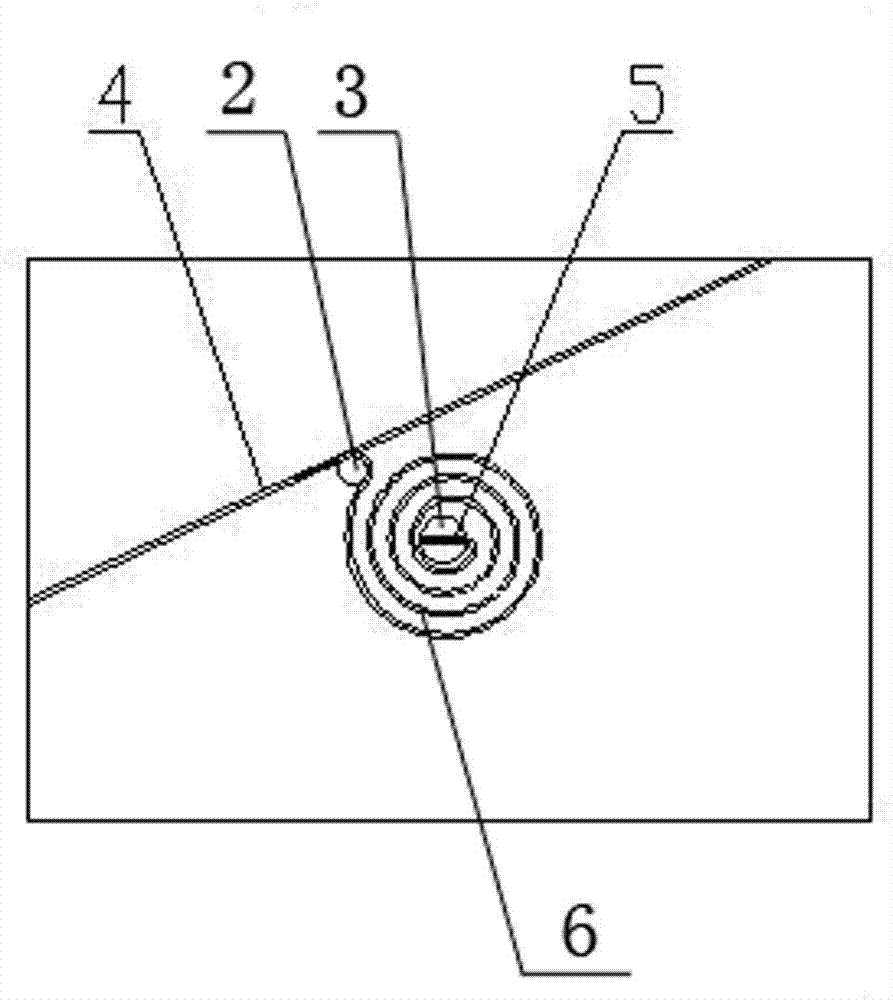

[0011] Referring to the accompanying drawings, a disc spring bending device includes a base 1 , a corner post 2 , and a post 3 for a disc spring. There are two circular blind holes in the middle of the upper end surface of the base 1, which are convenient for the insertion of the angled column 2 and the disc-shaped spring clamping column 3 and are fixed by the interference method. The position above the upper end surface of the protruding base 1 of the disc spring clip 3 is provided with a disc spring clamping groove 5, which is used for inserting and clamping the starting end of the core of the disc spring 6 when corners are bent. One end of the angled column 2 is inserted into the blind hole of the base 1 and fixed with an interference fit, and the other end of the angled column 2 protrudes from the upper end surface of the base 1 to locate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com