Tool for machining inclined holes of force measuring wheel set of steel rail flaw detection car

A technology of rail flaw detection car and force measuring wheel set, which is applied to metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of machine tool equipment functions that cannot meet technical requirements, high manufacturing precision, complex structure, etc., and achieve design The structure is reasonable, the effect of improving work efficiency and optimizing the process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

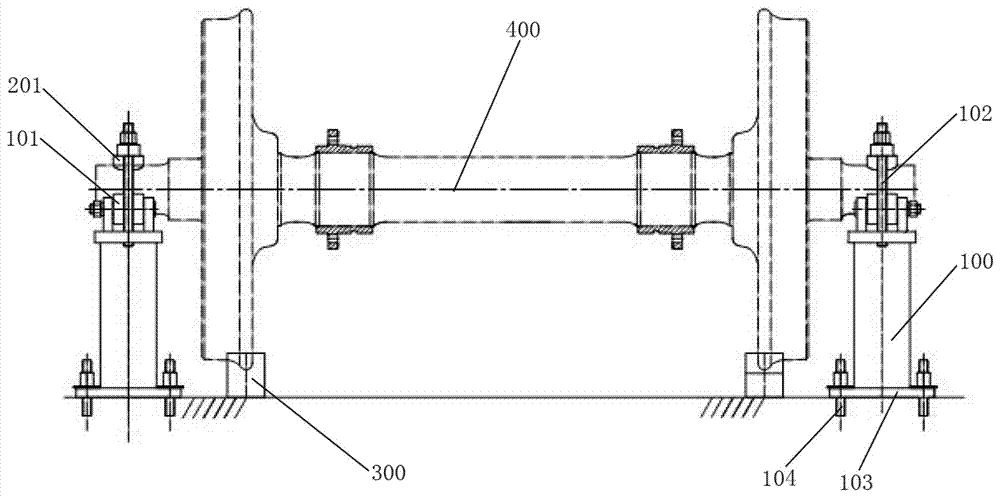

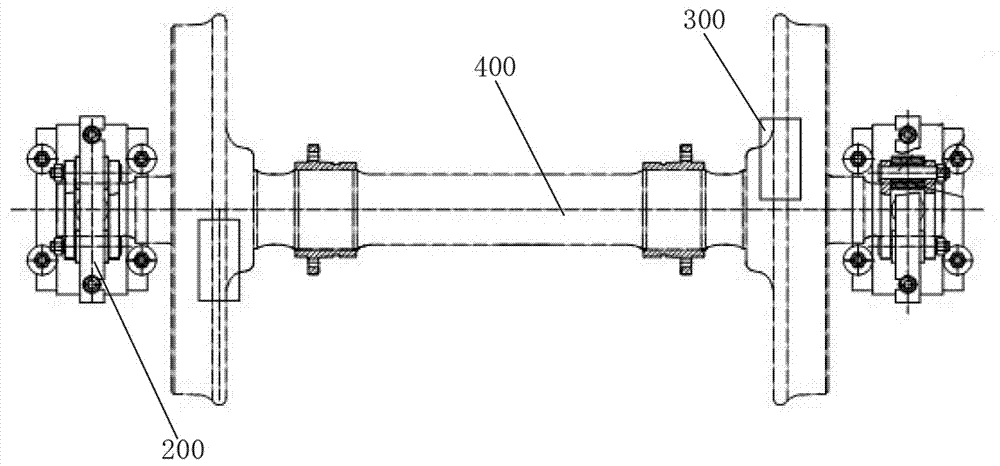

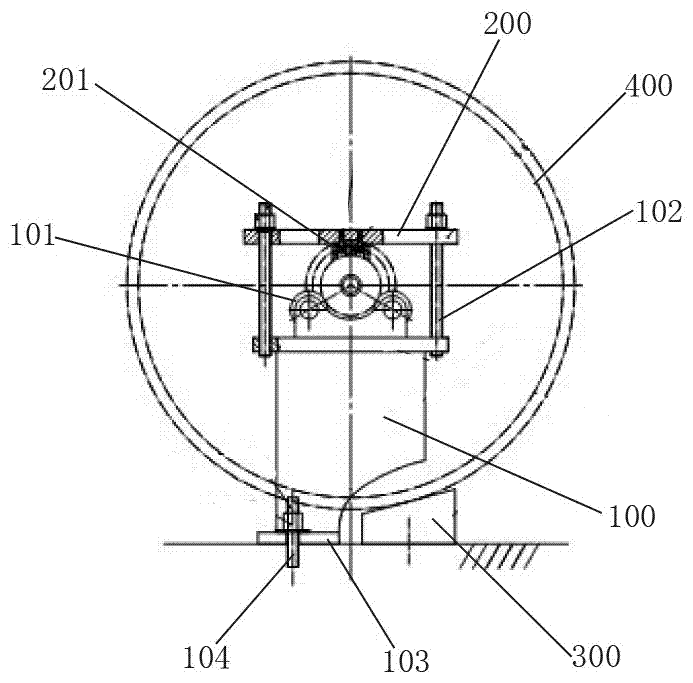

[0024] see Figure 1-Figure 8 , a tool for processing inclined holes in a force-measuring wheel pair of a rail flaw detection vehicle according to the present invention, comprising two support piers 100, a pressure plate 200 and a wedge 300, the two support piers 100 are arranged correspondingly on the left and right sides, and each support pier 100 is correspondingly provided with two supports The rollers 101 and both ends of the axle of the force-measuring wheel set 400 are matched and placed between the two support rollers 101; Tightly connected and fixed, the force-measuring wheel set 400 is matched and fixed between the pressure plate 200 and the support roller 101, and a briquetting block 201 is also arranged between the pressure plate 200 and the axle of the force-measuring wheel set 400, and the briquetting block 201 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com