Oxidation, sintering and film-coating integrated device for producing high-purity dumet wire coatings

A cladding layer and high-purity technology, which is applied to the surface coating liquid device, solid-state diffusion coating, coating, etc., can solve the problems of shortened service life, easy falling off, cracking, and scrapping of finished Dumet silk of downstream products increase in energy efficiency and risk, and achieve the effects of energy saving, optimization of product process structure, self-energy level of equipment and improvement of energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

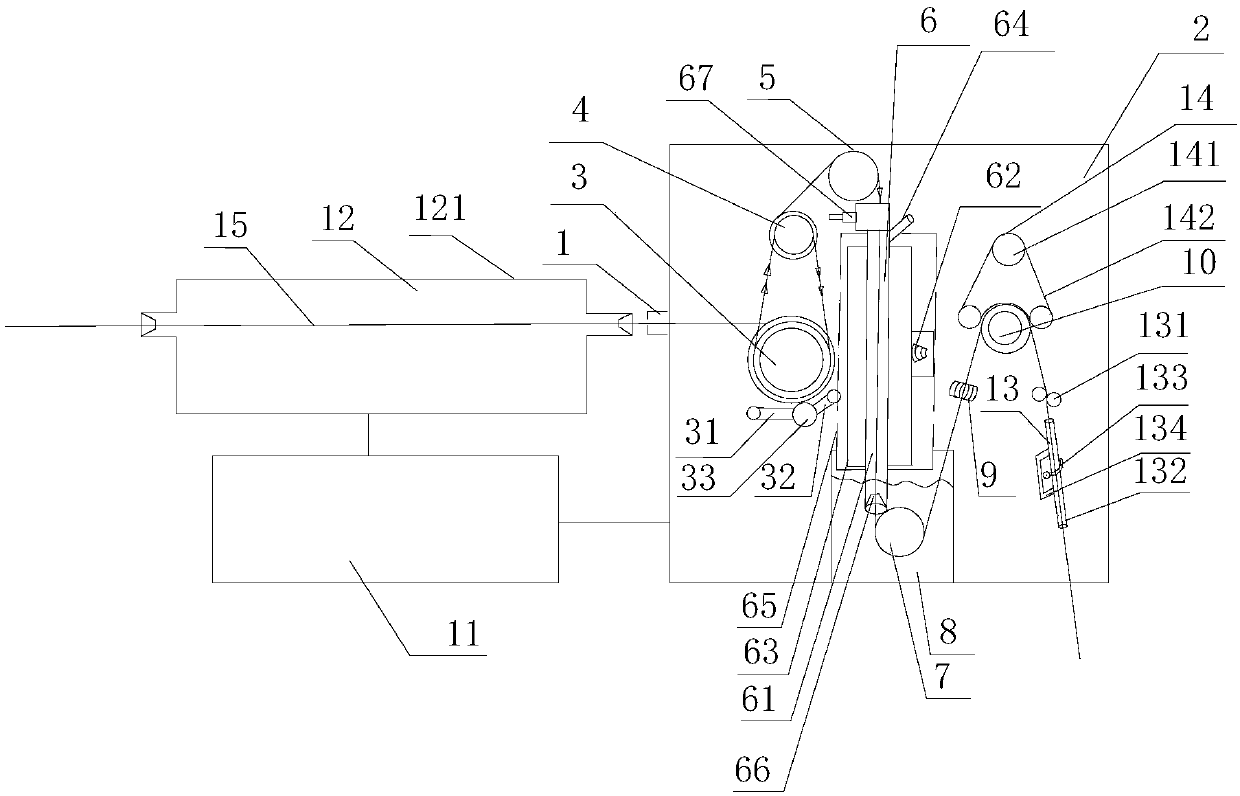

[0019] Example 1: An integrated device for oxidation, sintering and coating film production of high-purity Dumet silk coating, including cleaning port 1, Cu 2 O coating layer production screen 2, guide wire fixed speed wheel 3, wire splitting wheel 4, upper electrode guide wheel 5, integrated mixed gas reaction, sintering chamber 6, Cu 2O reaction and sintering integrated program control room, lower electrode guide wheel 7, PVA solution infiltration tank 8, air heating system 9 and synchronous fixed speed take-up wheel 10, the cleaned wire 15 is sent in from the cleaning port 1, and enters Cu 2 O-clad production screen 2, in Cu 2 O wrapping layer production screen passes through the guide wire fixed speed wheel 3, the wire dividing wheel 4, the upper electrode guide wheel 5, the integrated mixed gas reaction, the sintering chamber 6, the lower electrode guide wheel 7, the PVA solution infiltration tank 8, and the wind heat System 9 and synchronous fixed speed take-up reel 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com