Cellulose pulp pretreatment equipment

A cellulose pulp and pretreatment technology, applied in fiber raw material treatment, chemical/physical process, pulp raw material addition process, etc., can solve the problems of impregnation, swelling, poor mixing effect, etc., achieve uniform material, save engineering investment, The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

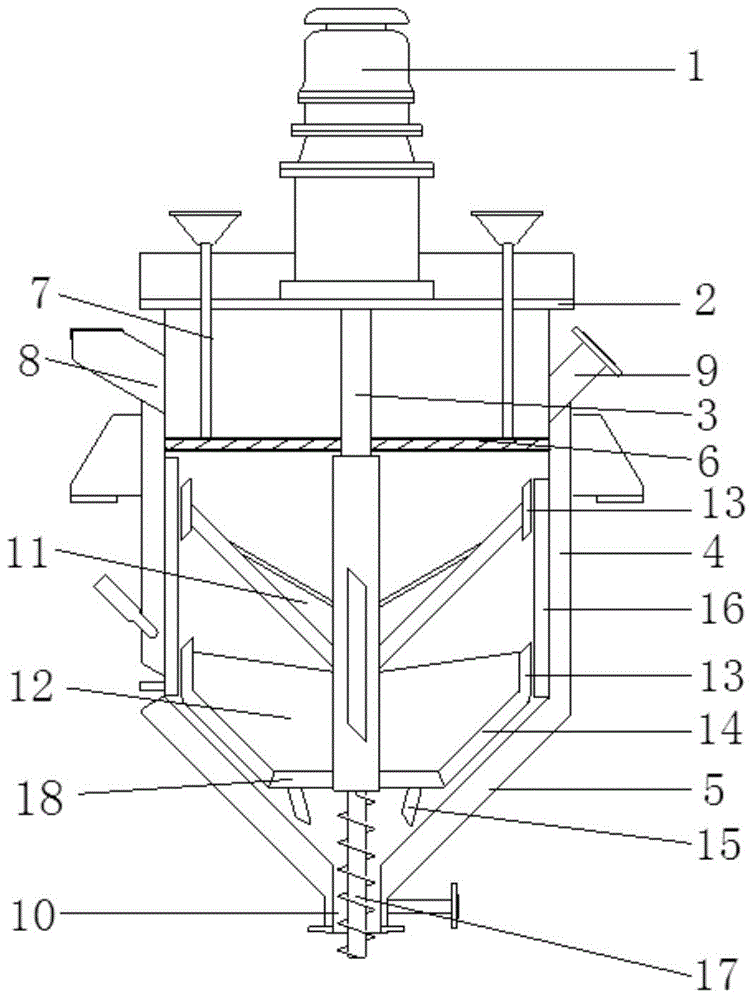

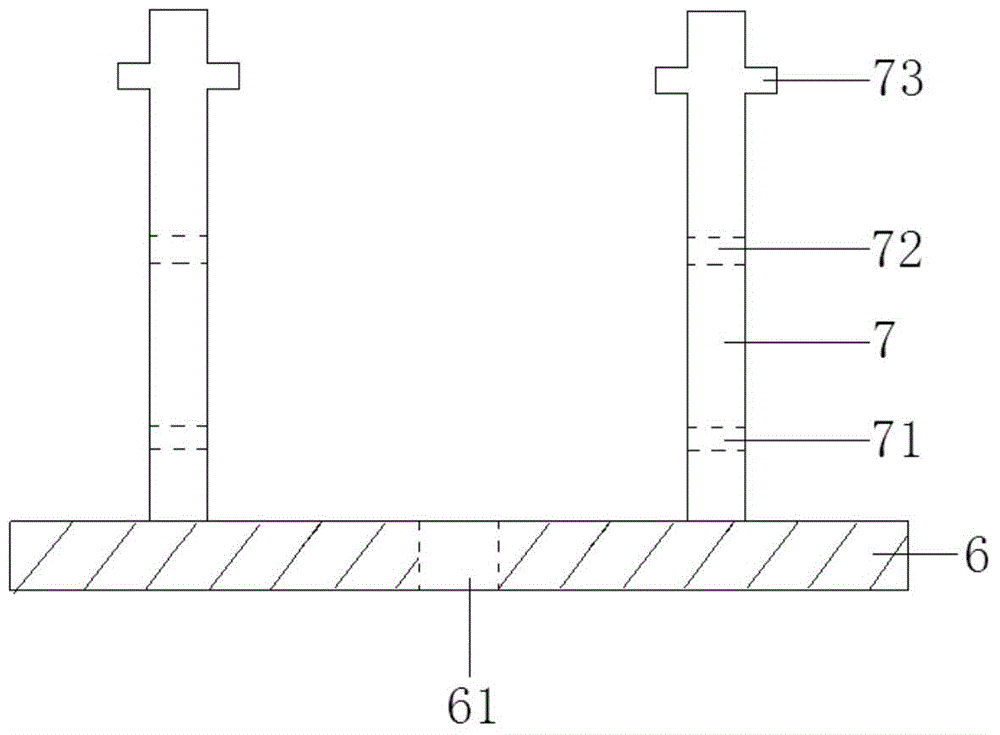

[0042] like figure 1 As shown, the cellulose pulp pretreatment equipment of the present invention includes a vertical stirring kettle, a kettle cover 2 is arranged above the kettle body 4, a motor 1 is arranged on the kettle cover 2, the stirring shaft 3 is connected with the motor 1, and the stirring shaft 3 extends Into the kettle body 4, a stirring paddle is arranged on the stirring shaft 3, and a porous pressing plate 6 is arranged above the stirring paddle in the kettle body 4. The porous pressing plate 6 is provided with many holes for the passage of the solvent. The porous pressing plate 6 and the kettle body 4 The cross-sections are matched to each other, the porous pressing plate 6 is provided with a central through hole 61 , the stirring shaft 3 is arranged through the central through hole 61 , and the porous pressing plate 6 can move up and down in the kettle body 4 .

[0043] The upper side of the perforated pressing plate 6 is provided with a tie rod 7 parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com