Sand spraying, washing and drying automation integrated device

An integrated, sandblasting technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of prolonging the process flow, consuming manpower and material resources, etc., and achieve the effect of improving quality, shortening material resources, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

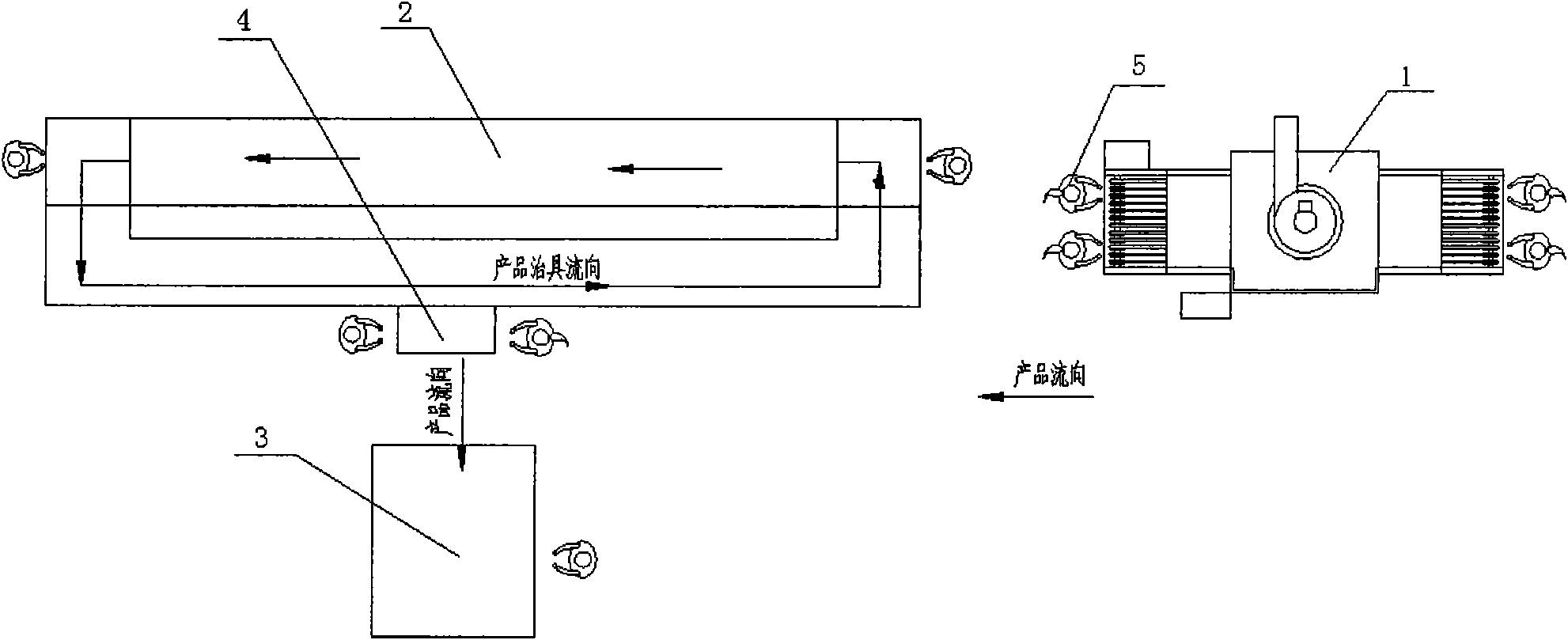

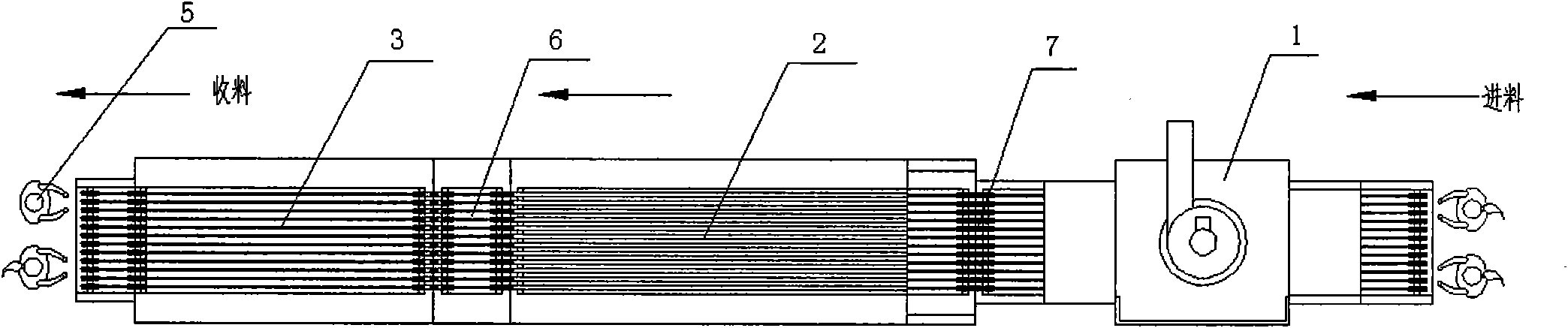

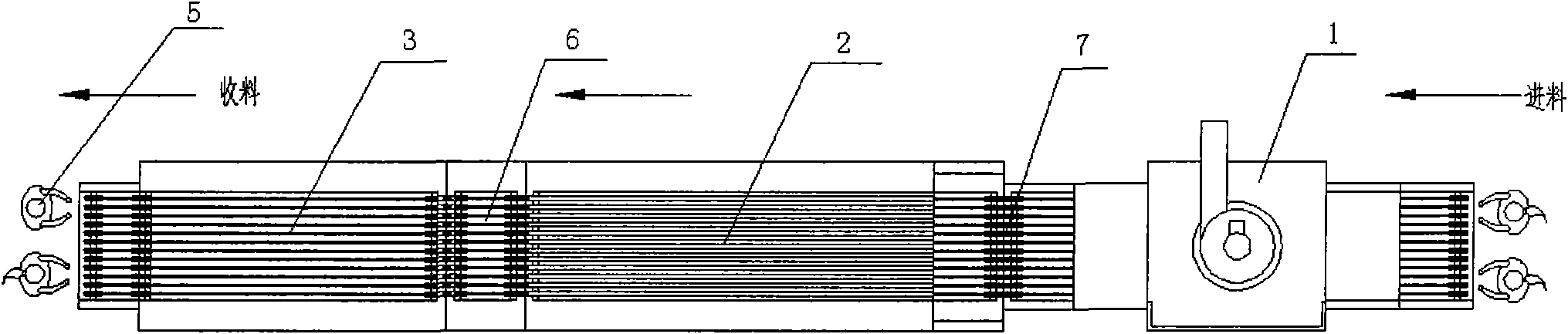

[0014] figure 2 It is a structural schematic diagram of an embodiment of the present invention.

[0015] Such as figure 2 Shown: sand blasting, water washing, drying automation integrated device, including sand blasting machine 1, high pressure cleaning machine 2, drying machine 3 and vacuum water removal device 6, the vacuum water removal device 6 is set in the high pressure cleaning machine 2 and the dryer 3, while the sandblasting machine 1, the high-pressure cleaner 2, the vacuum water removal device 6 and the dryer 3 are connected in sequence through the automatic transmission line 7. In addition, the total control system is connected with the Sand blasting machine 1, high-pressure cleaning machine 2, vacuum dewatering device 6 and sub-control system in dryer 3 are connected.

[0016] The present invention only needs staff 5 to operate at the feeding and discharging positions, and other processing processes are all controlled and automatically carried out through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com