A detachable filling retaining wall

A dismantling and retaining wall technology, which can be used in fillings, safety devices, mining equipment, etc., can solve the problems of high cost and complicated construction, and achieve the effects of simple construction, firm structure and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

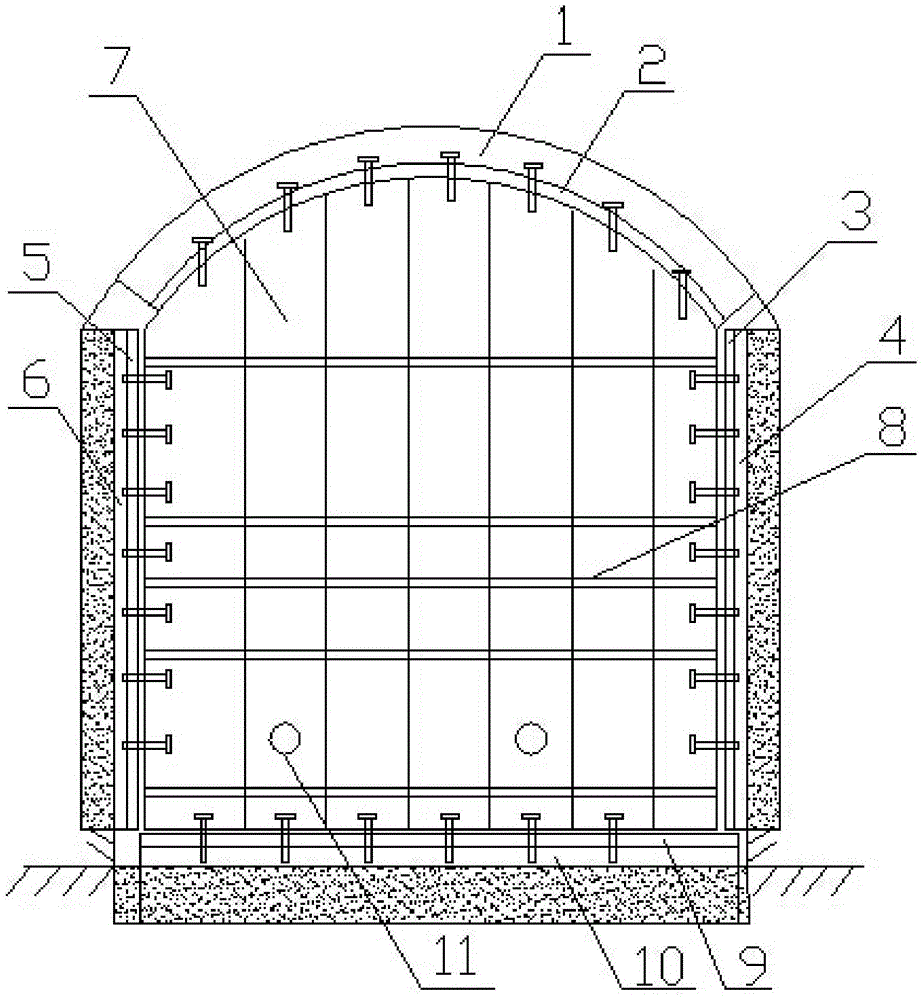

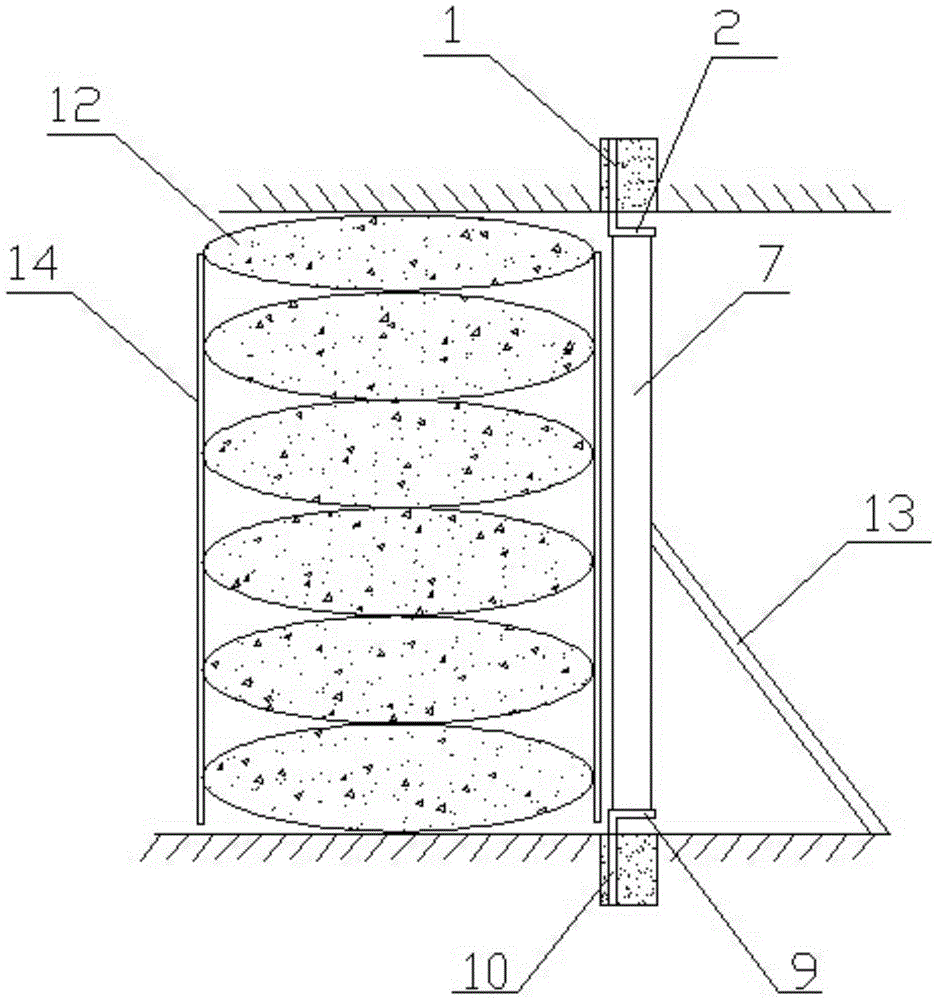

[0028] See attached figure 1 and 2 , a detachable filling retaining wall provided by the present invention is used for filling roadways, and the filling retaining wall includes: a sandbag partition wall, a first fixing part, a second fixing part and a support assembly. The sandbag partition wall includes: a plurality of sandbags 12, the sandbags 12 are filled with tailings and wrapped with tailings. As a preferred embodiment, the sandbags 12 are formed by filling and encapsulating the tailings with gunny bags or woven bags. Multiple sandbags 12 are stacked vertically to fill up the vertical section of the entire roadway, that is, multiple sandbags 12 are stacked at the set position of the construction filling retaining wall, and they are compacted as much as possible during the stacking pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com