Oil way distributor for double-acting hydraulic cylinder fixture

A technology of double-acting hydraulic cylinders and oil circuit distributors, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., to achieve the effects of simplifying the processing technology, reducing tediousness, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

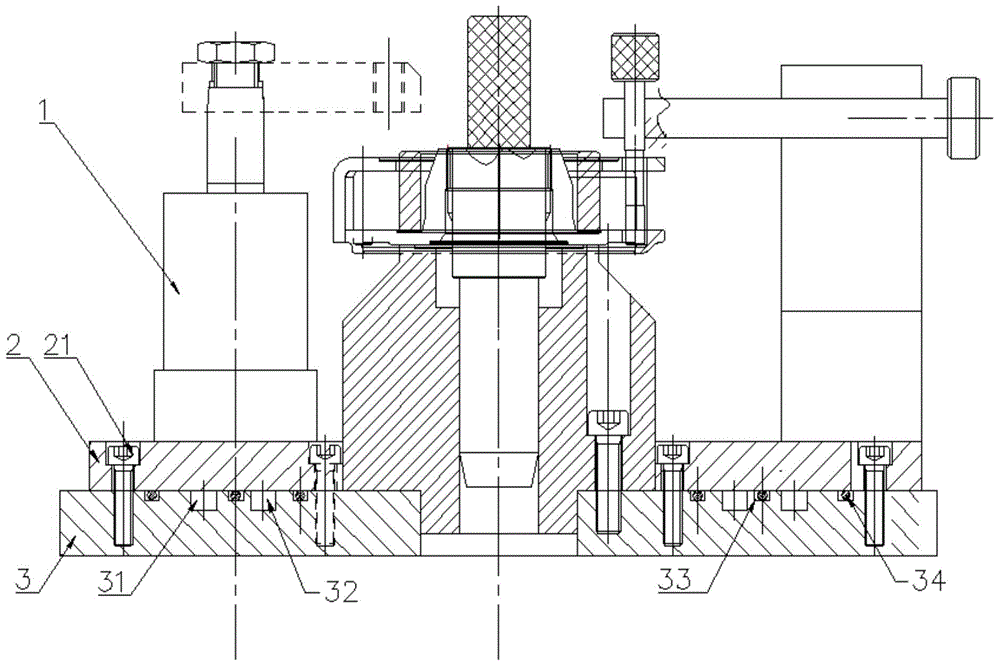

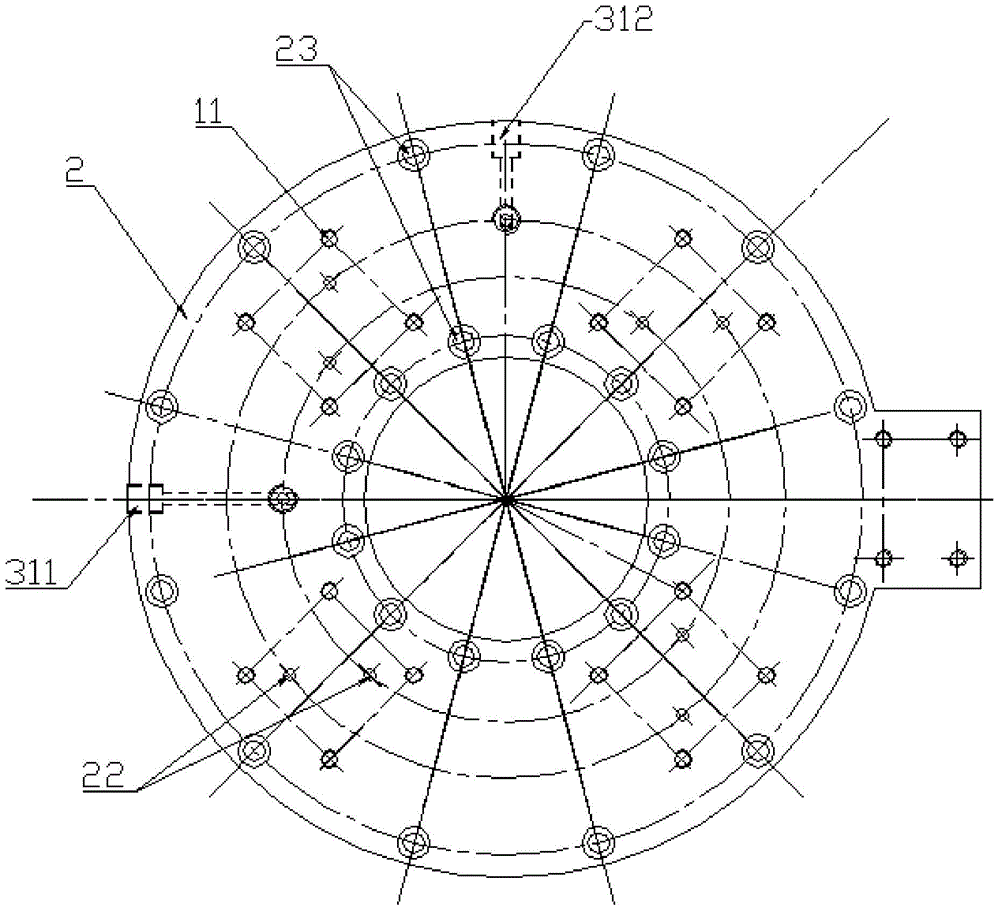

[0025] Such as Figure 1-4 As shown, an oil circuit distributor for a double-acting hydraulic cylinder fixture, which includes an oil cylinder connecting plate 2 and an oil circuit plate 3;

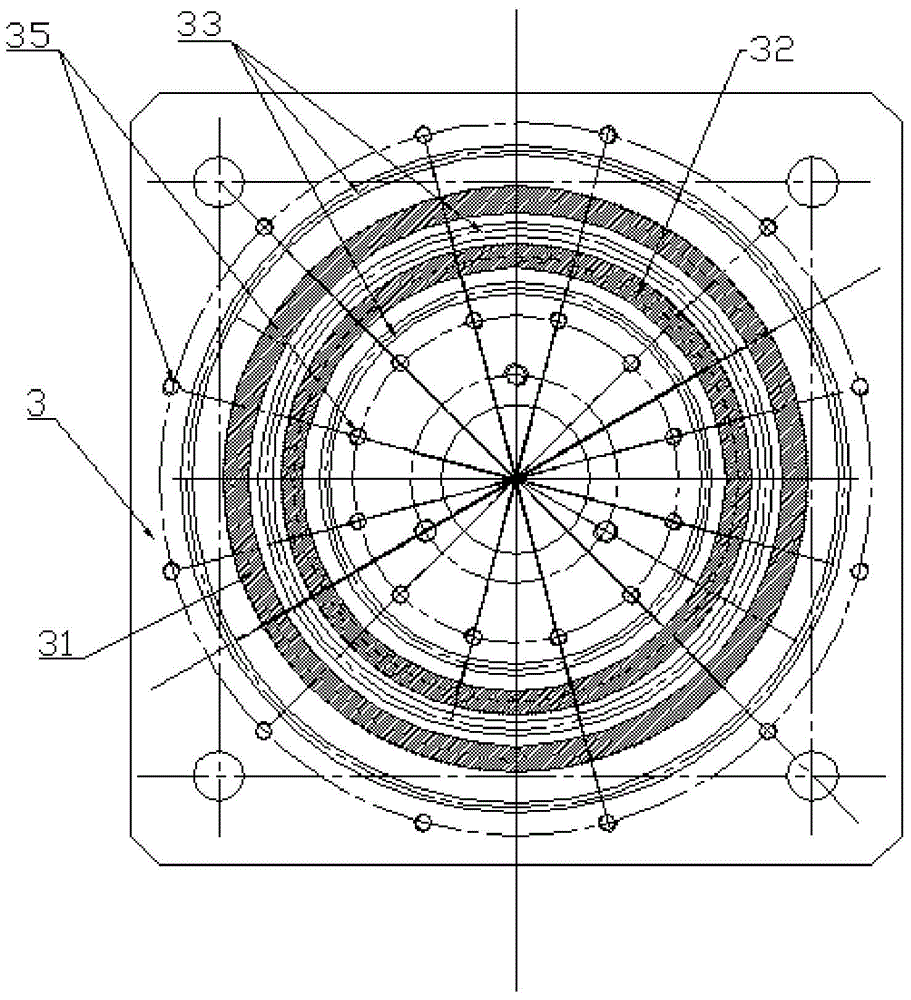

[0026] The upper end surface of the oil circuit plate 3 is in sealing connection with the oil cylinder connecting plate 2, and the oil circuit plate 3 is respectively provided with an annular locking oil groove 31 and an annular loosening oil groove 32, and the locking oil groove 31 and the releasing oil groove The oil grooves 32 are concentric, and there are annular sealing grooves 33 on the oil circuit board 3 on both sides of the locking oil groove 31 and the loosening oil groove 32, and the oil between the loosening oil groove 32 and the locking oil groove 31 There is only one sealing groove 33 on the circuit board 3, and an O-ring 34 matched with it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com