Three-stage pressure reducer

A technology of pressure reducer and pressure reducing valve, which is applied to safety valves, engine components, balance valves, etc., can solve the problems of workpiece breakage / poor interface quality, large pressure change of pressure reducer, unstable low-pressure gas, etc. The effect of stable air pressure, reduced pressure drop and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

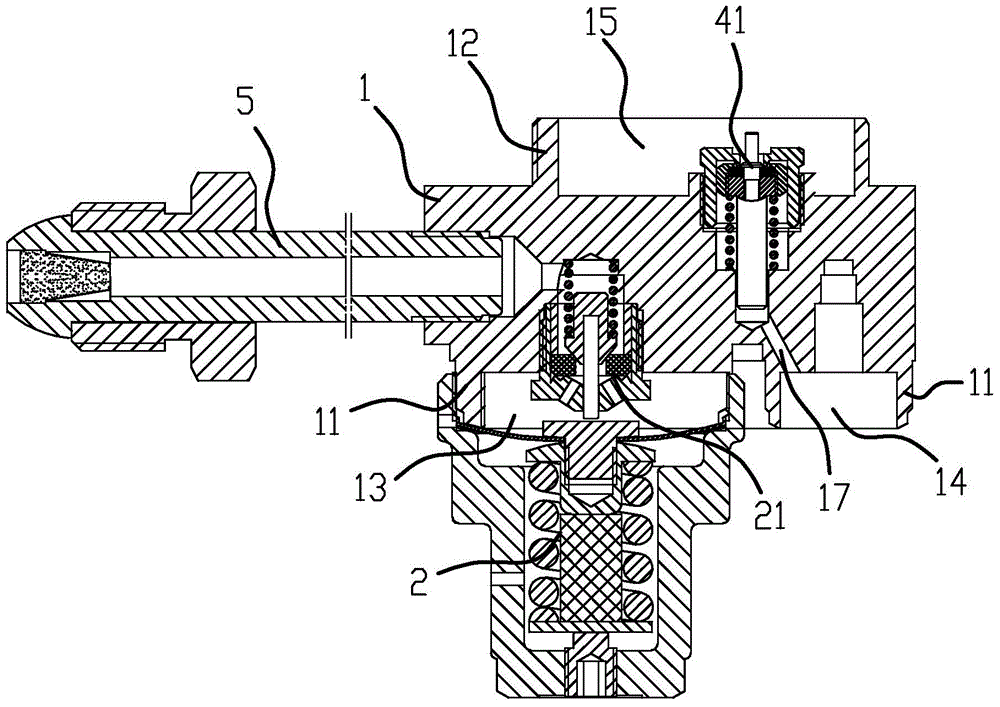

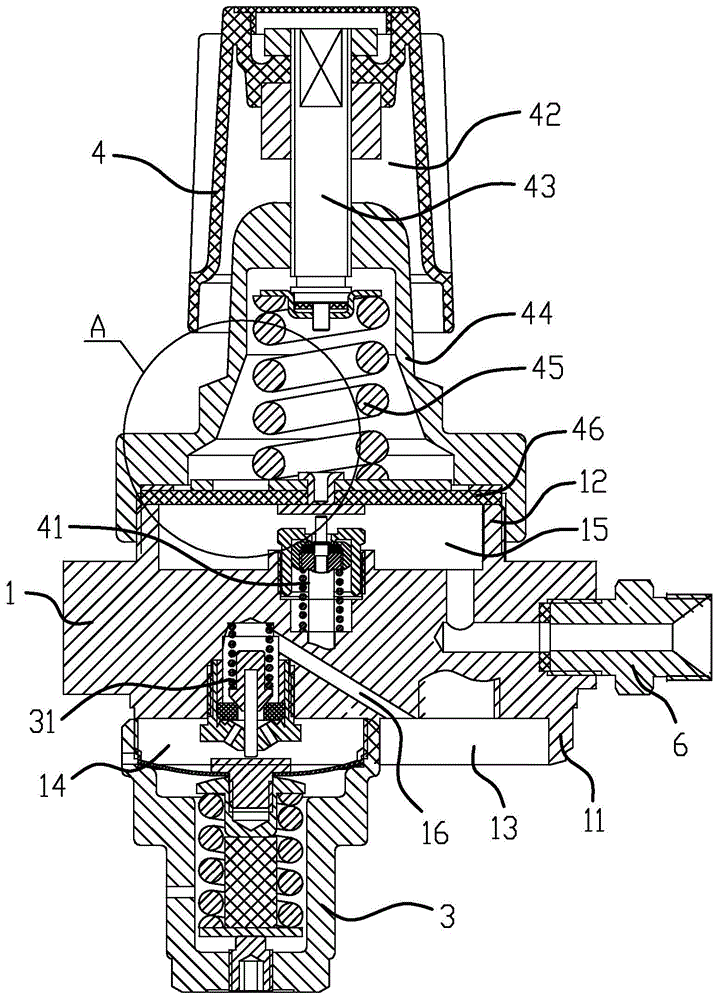

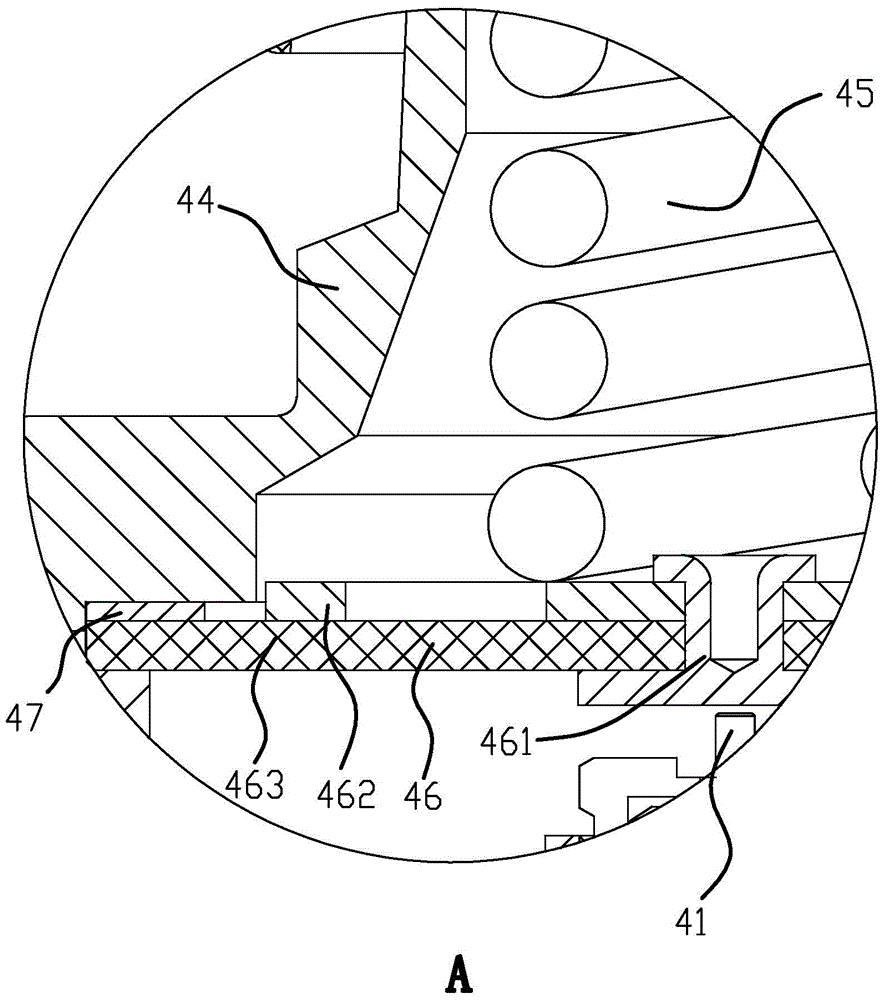

[0026] Such as Figure 1 to Figure 5 As shown, the three-stage pressure reducer includes a valve body 1, an inlet pipe 5 installed on the valve body 1, an outlet pipe 6, a high pressure gauge 81, a low pressure gauge 8, and a first-stage decompression valve installed on the valve body 1 respectively. Valve cover 2, secondary pressure reducing valve cover 3 and main pressure reducing valve cover 4, primary pressure reducing valve cover 2 and valve body 1 form a primary pressure reducing chamber 13, secondary pressure reducing valve cover 3 and valve body 1 forms a secondary decompression chamber 14, a main decompression chamber 15 is formed between the main decompression valve cover 4 and the valve body 1, a primary valve 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap