How to assemble lithium-ion battery modules

A lithium-ion battery and battery module technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, can solve the problems of time-consuming, labor-intensive, and difficult operation, and achieve simple operation, improved grouping efficiency, and energy saving the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

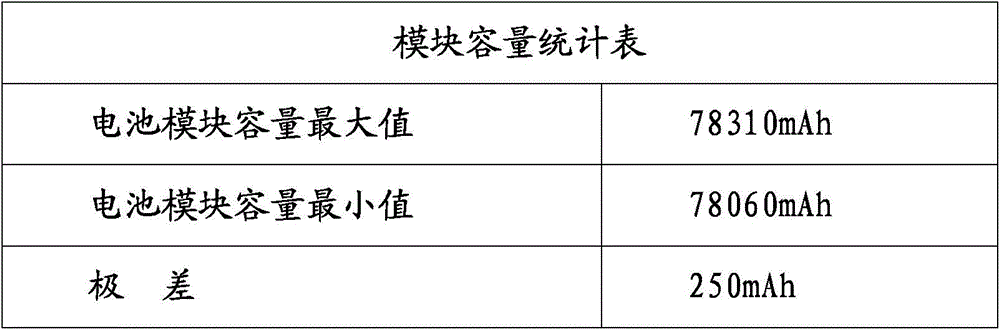

[0018] Take the 10F14 batch capacity of the produced IFP1965140 model 10F14 3000 fully charged batteries with a capacity range of 12.5-13.8Ah, which are required to be combined into 6 parallel modules. The capacity difference between modules is required to be 480mAh. The process and test data are as follows:

[0019] The range requirement between battery modules is 480mAh, and the number of parallel batteries in each battery module is 6, so the capacity gear interval Z=480 / 6=80mAh;

[0020] Test 3,000 batteries according to their capacity, and classify the batteries that meet the capacity range of 12.5-13.8Ah into 16 levels according to the capacity standard of 80mh;

[0021] The selected gears can be combined in the following three sequence forms:

[0022] Gear sequence of Group 1: 1, 4, 7, 10, 13, 16;

[0023] Gear sequence of group 2: 2, 5, 8, 9, 12, 15;

[0024] Gear sequence of group 3: 3, 6, 8, 9, 11, 14;

[0025] And 1+4+7+10+13+16=2+5+8+9+12+15=3+6+9+8+11+14=51; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com