Patents

Literature

155results about How to "Improve group efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

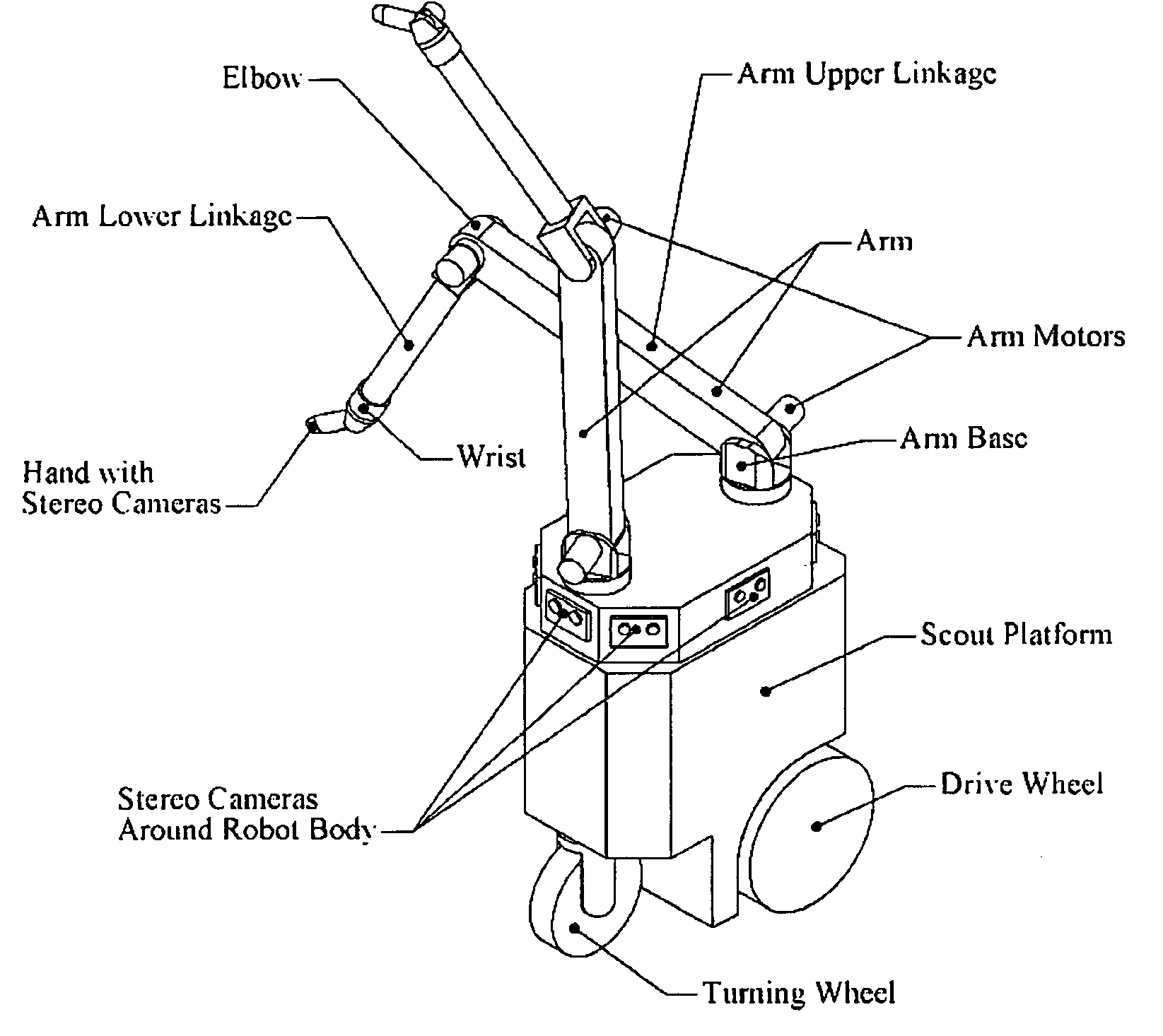

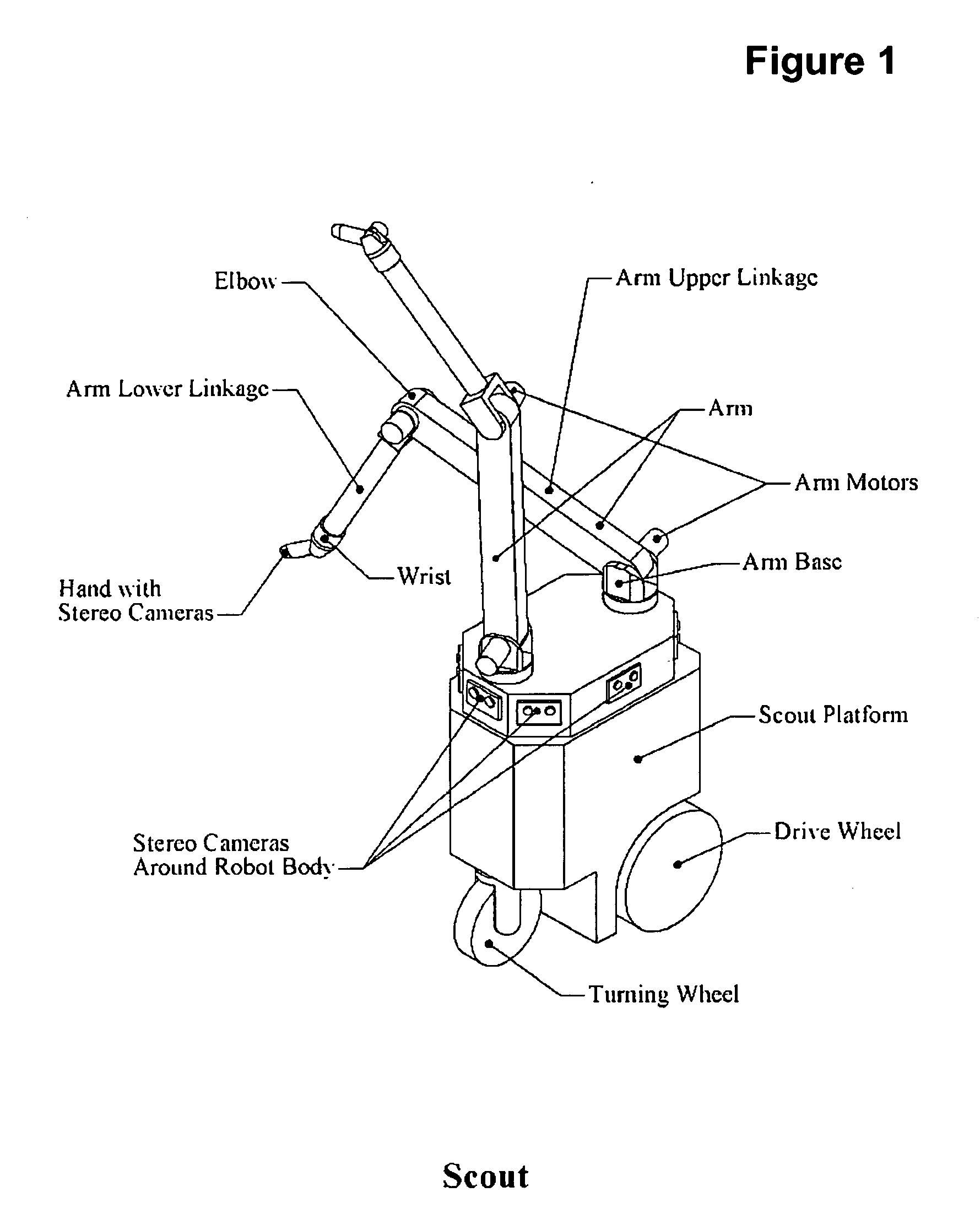

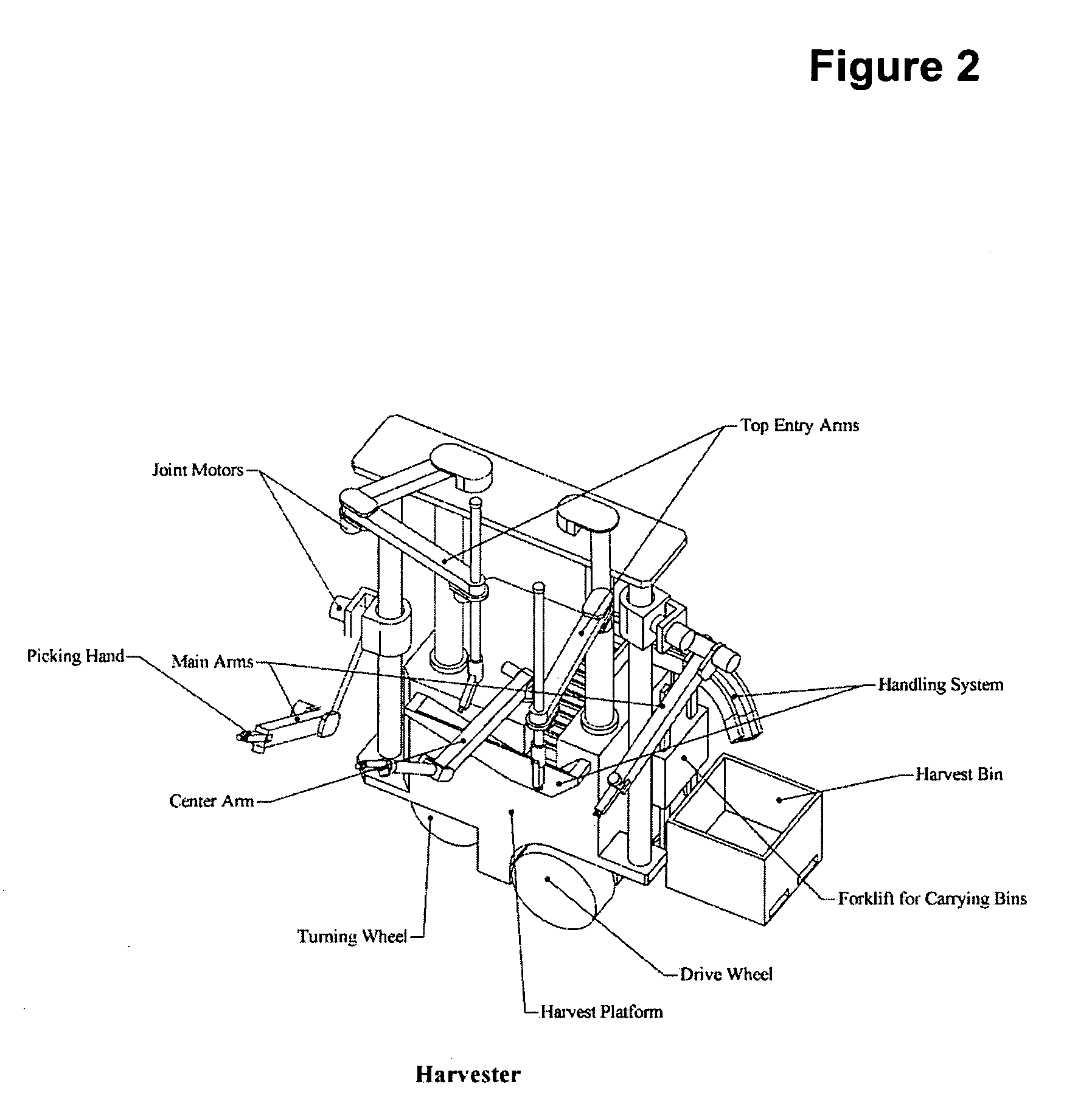

Agricultural robot system and method

InactiveUS20060213167A1Maximize efficiencyMaximizing cost-effectivenessAnalogue computers for trafficMowersMachine visionAction plan

An agricultural robot system and method of harvesting, pruning, culling, weeding, measuring and managing of agricultural crops. Uses autonomous and semi-autonomous robot(s) comprising machine-vision using cameras that identify and locate the fruit on each tree, points on a vine to prune, etc., or may be utilized in measuring agricultural parameters or aid in managing agricultural resources. The cameras may be coupled with an arm or other implement to allow views from inside the plant when performing the desired agricultural function. A robot moves through a field first to “map” the plant locations, number and size of fruit and approximate positions of fruit or map the cordons and canes of grape vines. Once the map is complete, a robot or server can create an action plan that a robot may implement. An action plan may comprise operations and data specifying the agricultural function to perform.

Owner:VISION ROBOTICS

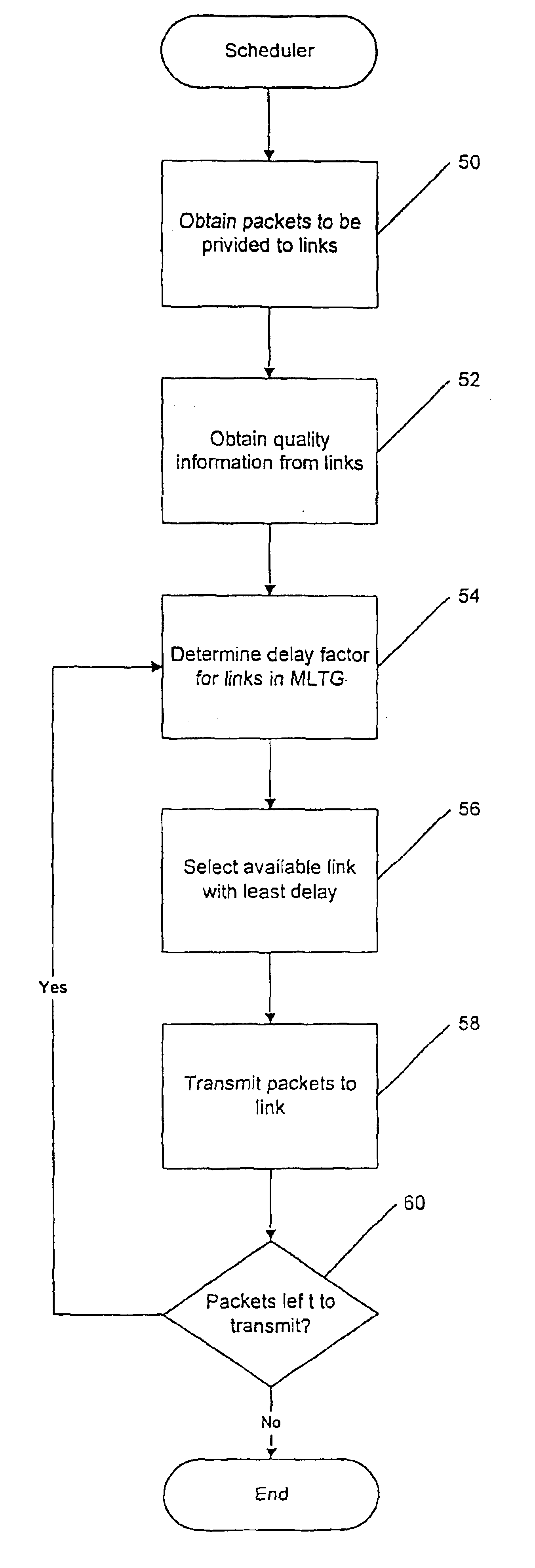

Optimal link scheduling for multiple links

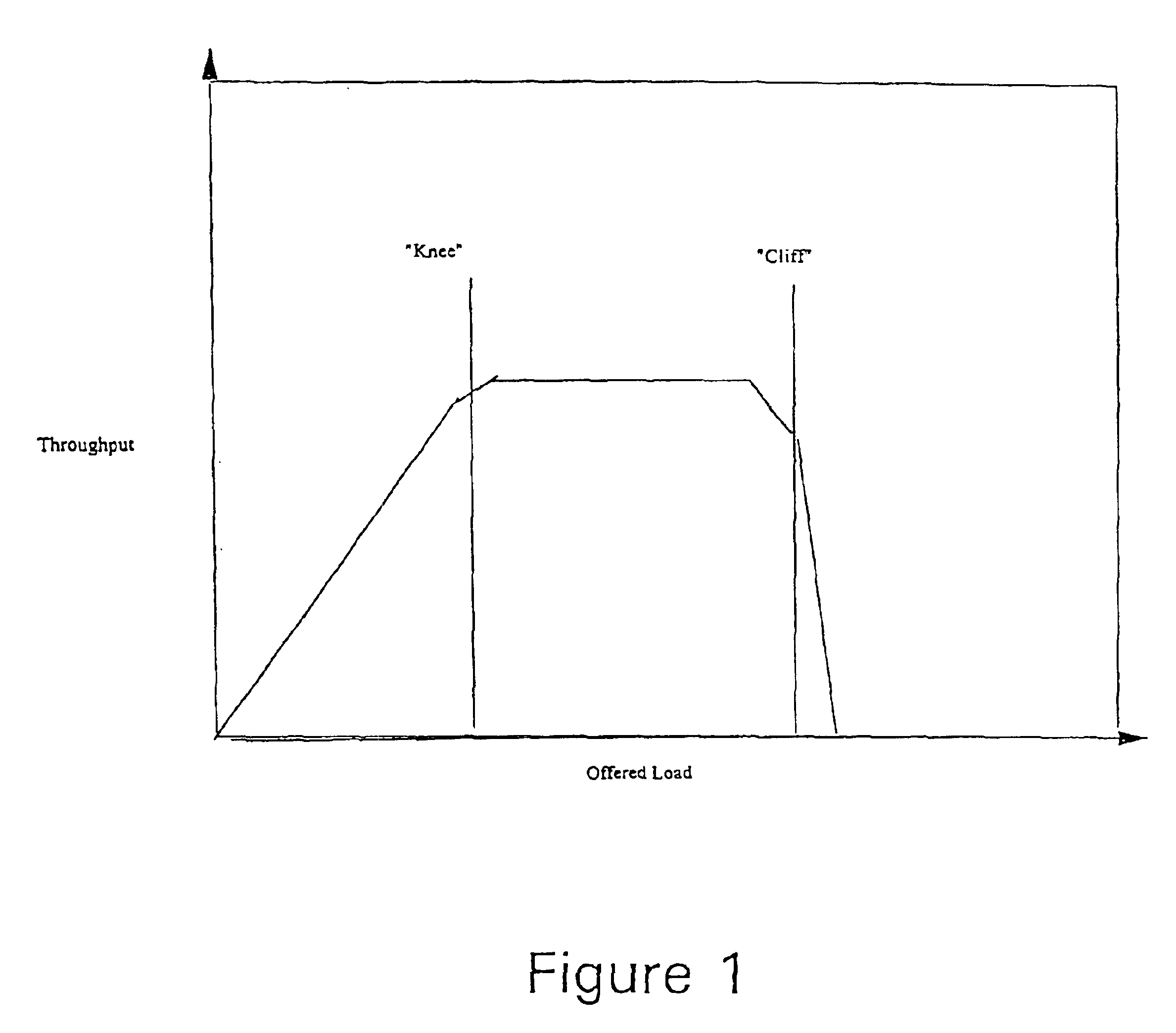

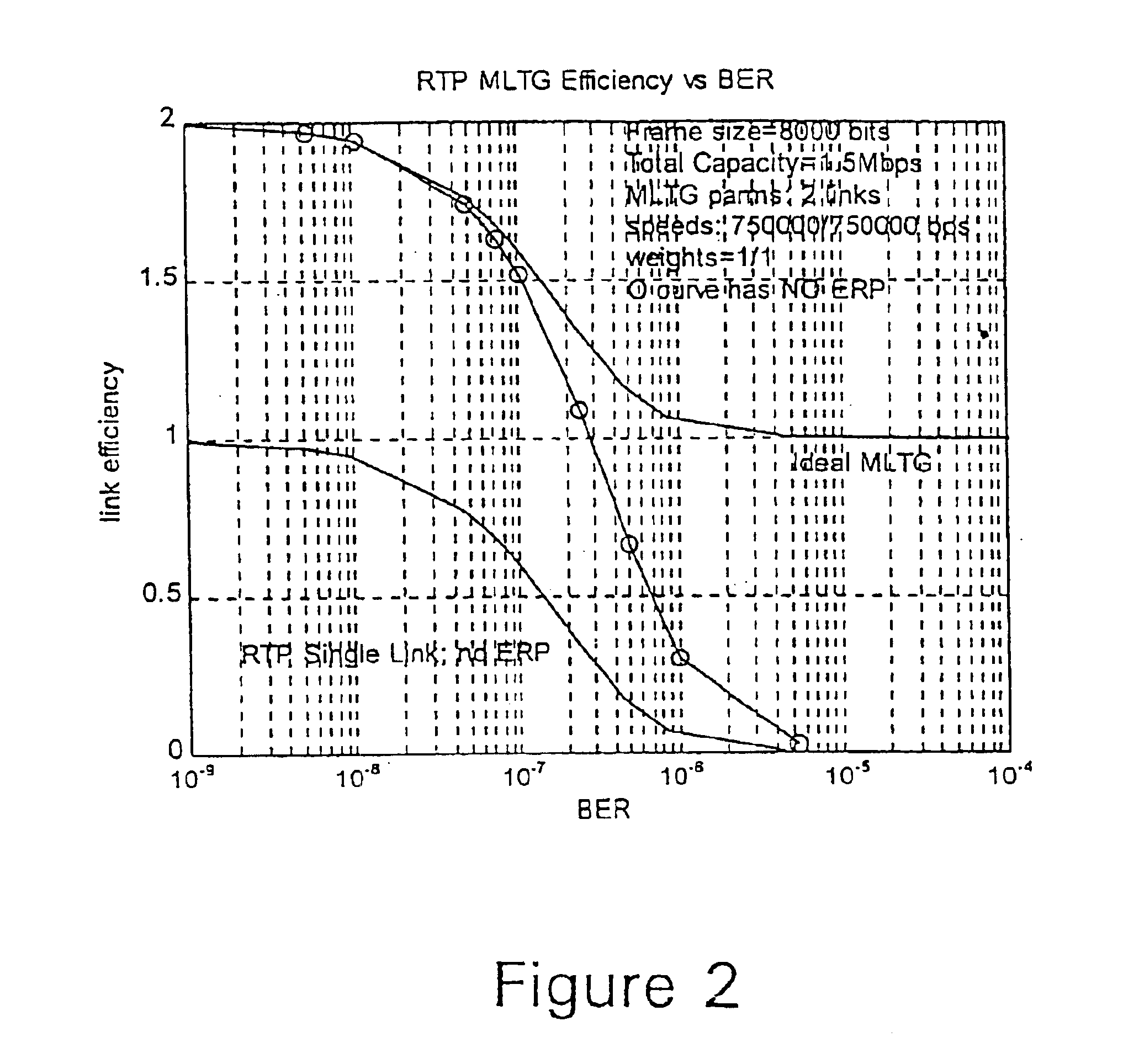

InactiveUS6862618B1Easy flow controlImprove efficiencyTime-division multiplexMultiple digital computer combinationsTime delaysLow delay

Methods, apparatus and computer program products are provided for distributing communication packets over multiple concurrent parallel links between a first node and a second node in a communication network based upon link quality information for the links. By utilizing link quality information from the links, the rate at which packets are provided to the links may be made proportional to the quality of the link, and thus, the link's ability to transmit the packet. The rate at which packets are provided to links may be reduced when error rates on a link exceed a specified threshold and eliminated when error rates exceed a higher threshold. Alternatively, timing delays from errors on a link may be used to determine a delay factor for a link and packets scheduled to the links based on the link with the lowest delay. The present invention is particularly useful in High Performance Routing Multilink Transmission Groups.

Owner:IBM CORP

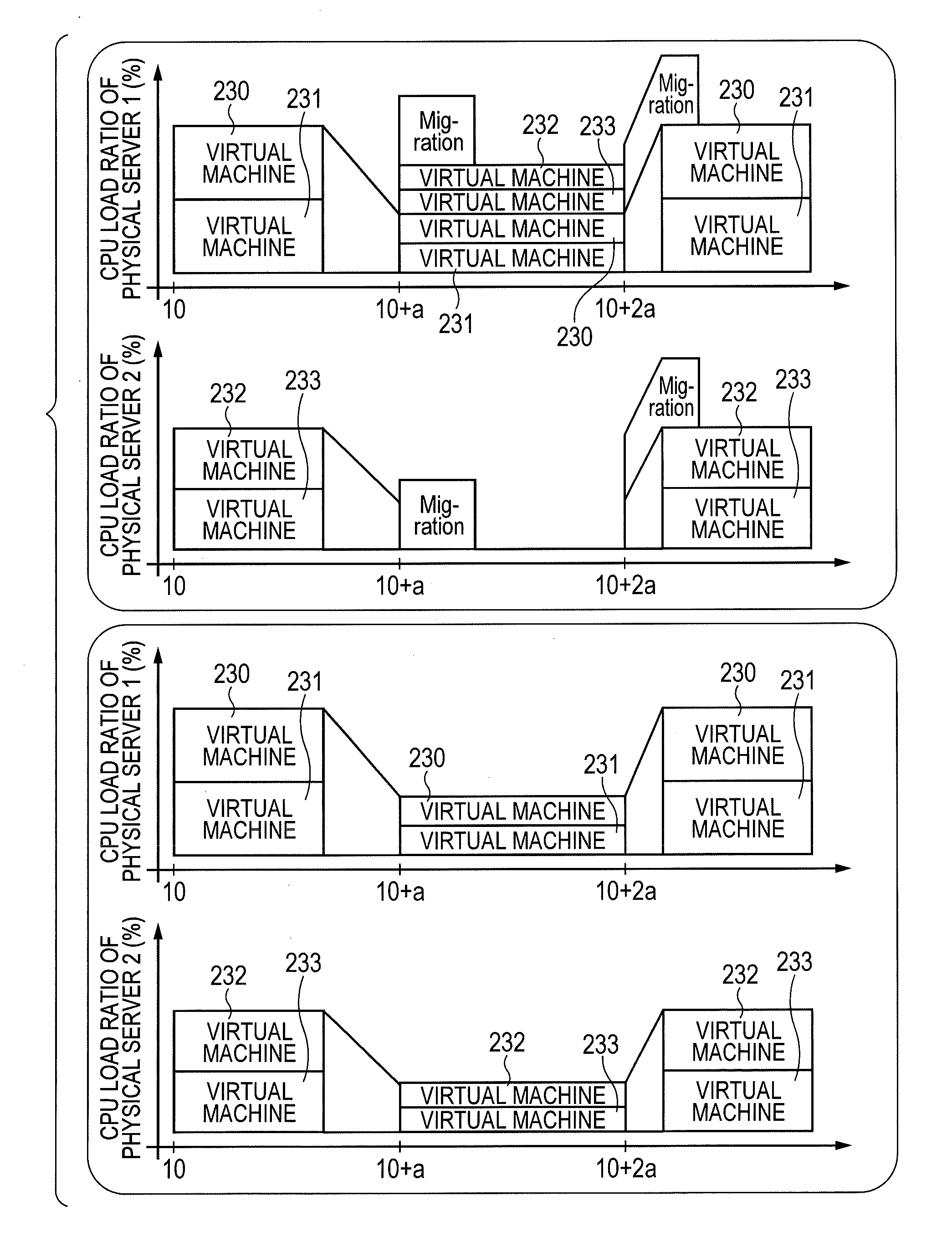

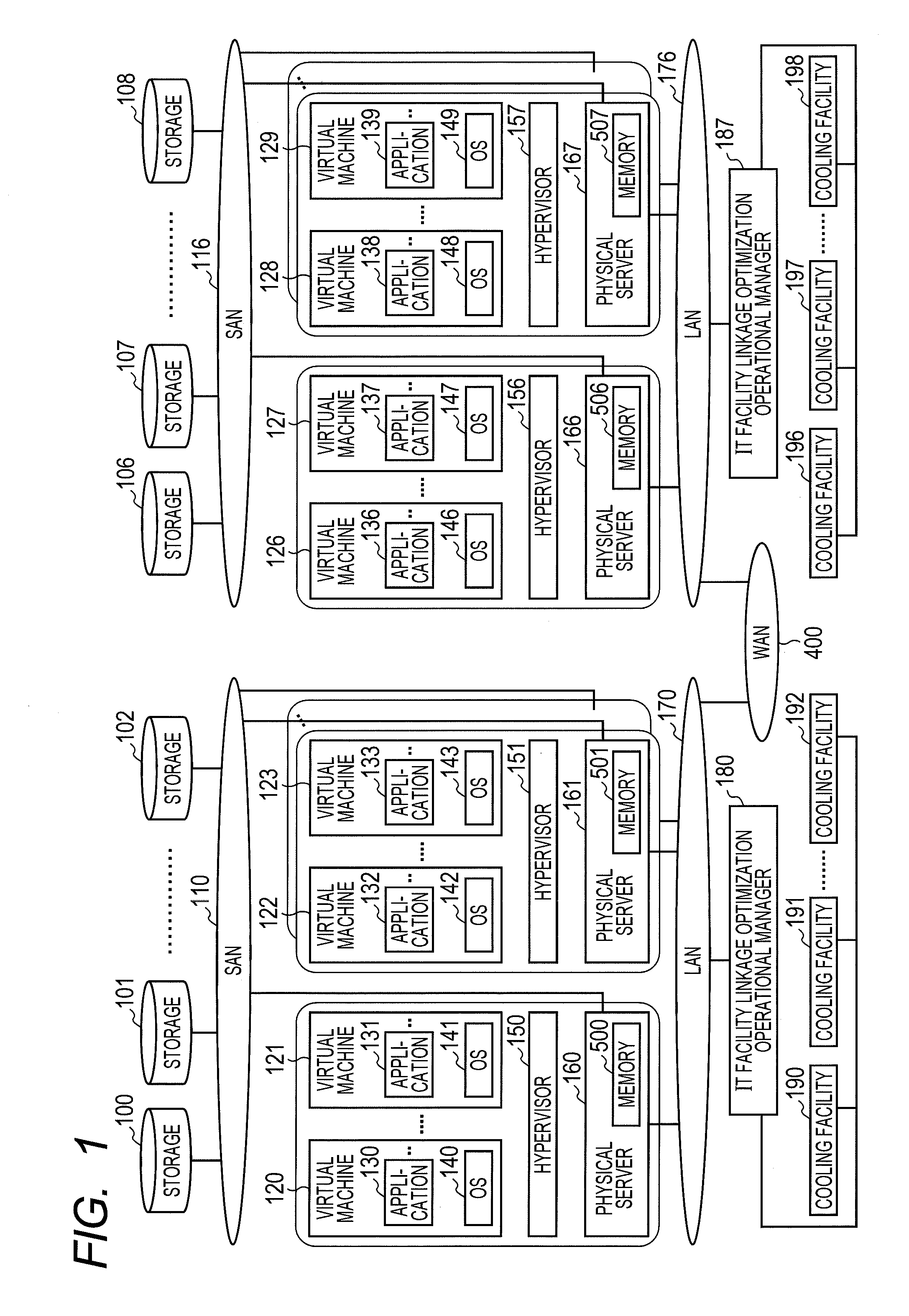

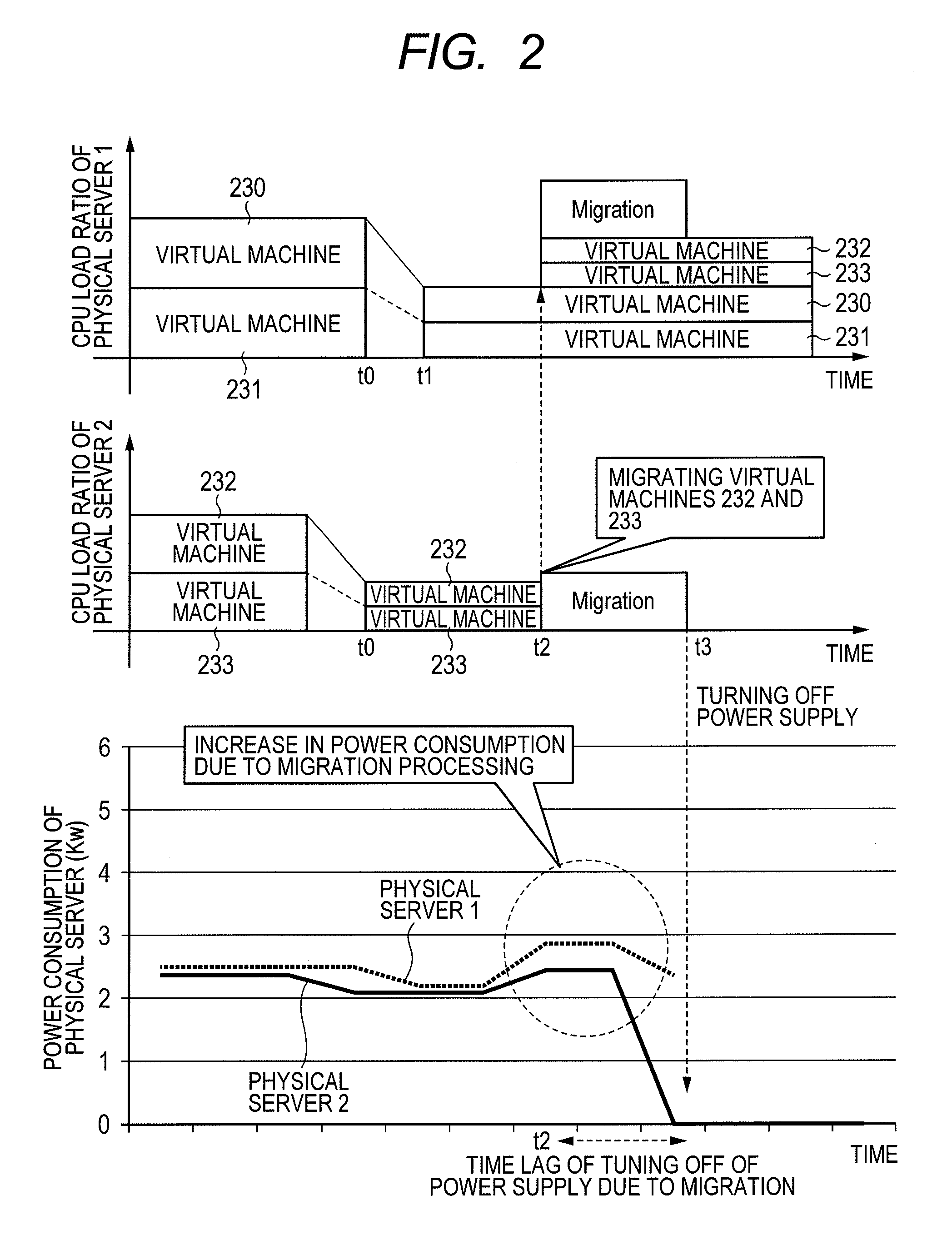

Information Processing System, and Its Power-Saving Control Method and Device

ActiveUS20130111492A1Improve performanceImprove conversion efficiencyEnergy efficient ICTResource allocationInformation processingWorkload

Pieces of working information on workloads, positions of the workloads, pieces of environmental information on cooling facilities, and positions of the cooling facilities are stored as arrangement information. The pieces of working information on the workloads are estimated, and allocation of tentative workloads is deduced for fear the pieces of working information may exceed the performances of a group of information processing devices. Tentative power consumptions and arrangement information resulting from the allocation of the tentative workloads, and tentative power consumptions and arrangement information necessary for the allocation of the tentative workloads are calculated. Tentative cooling powers required to control the cooling facilities are calculated. Allocation of the tentative workloads minimizing the sum total of the tentative power consumptions of the information processing devices and the tentative cooling powers of the cooling facilities is searched. Based on the searched allocation, the workloads are allocated to the information processing devices.

Owner:HITACHI LTD

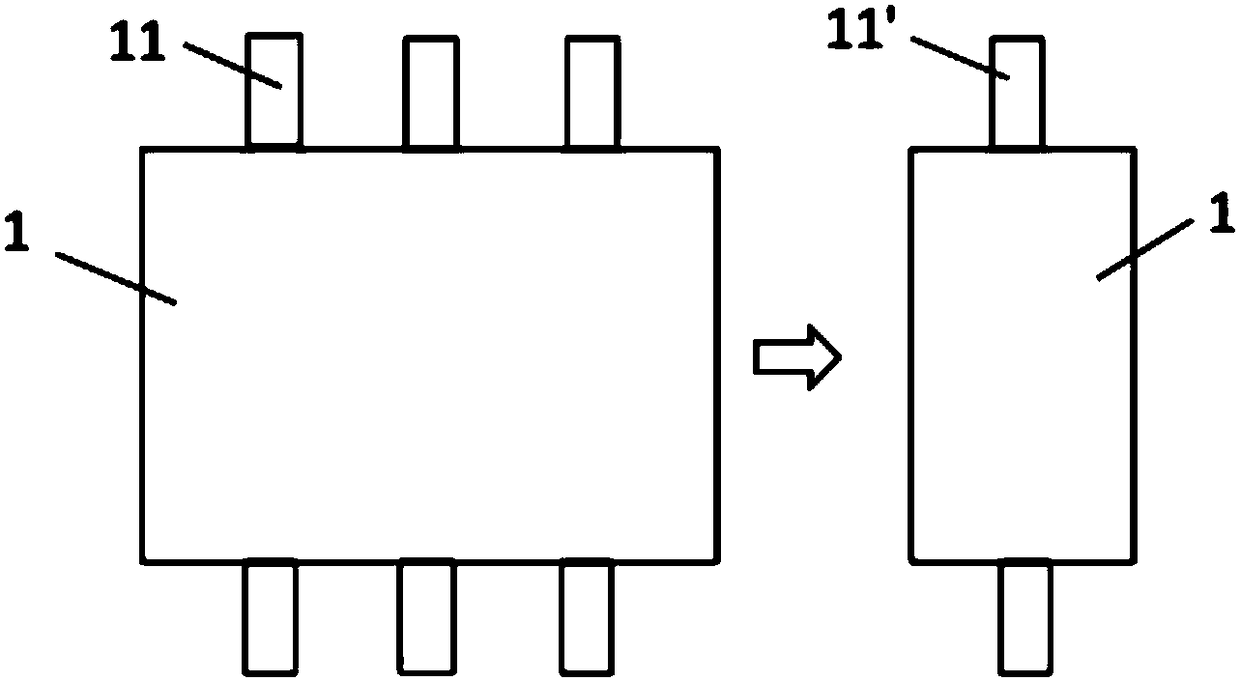

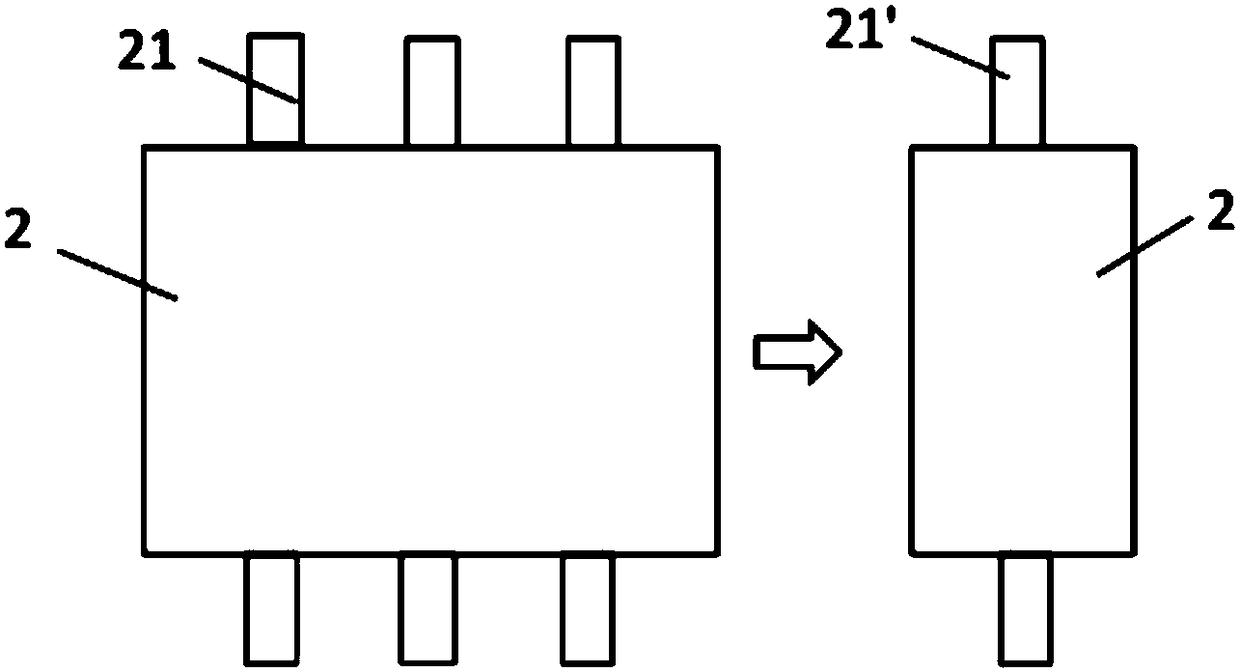

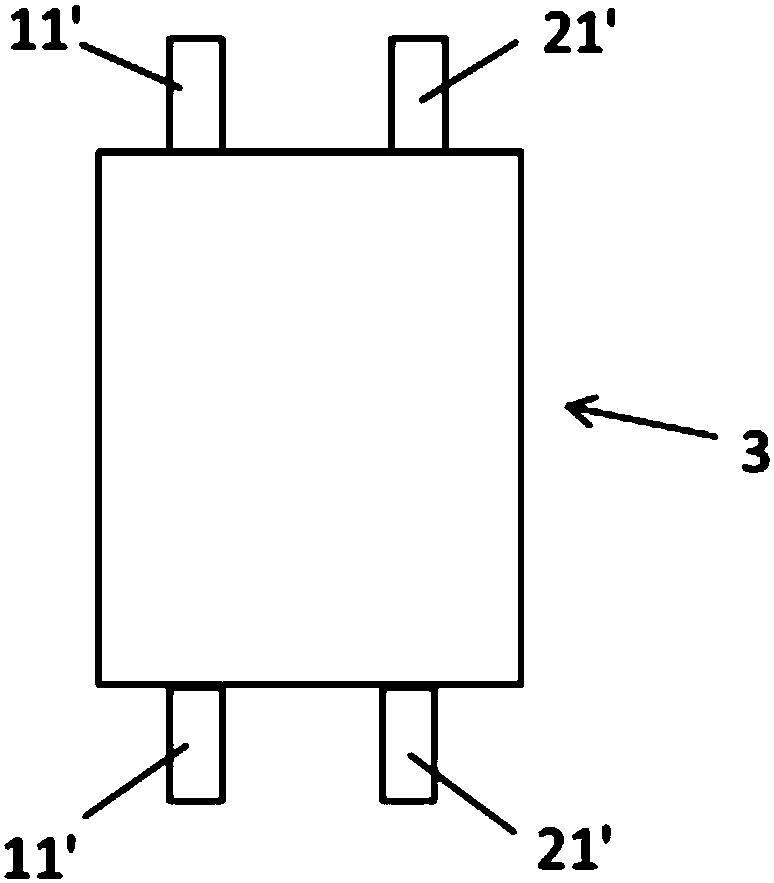

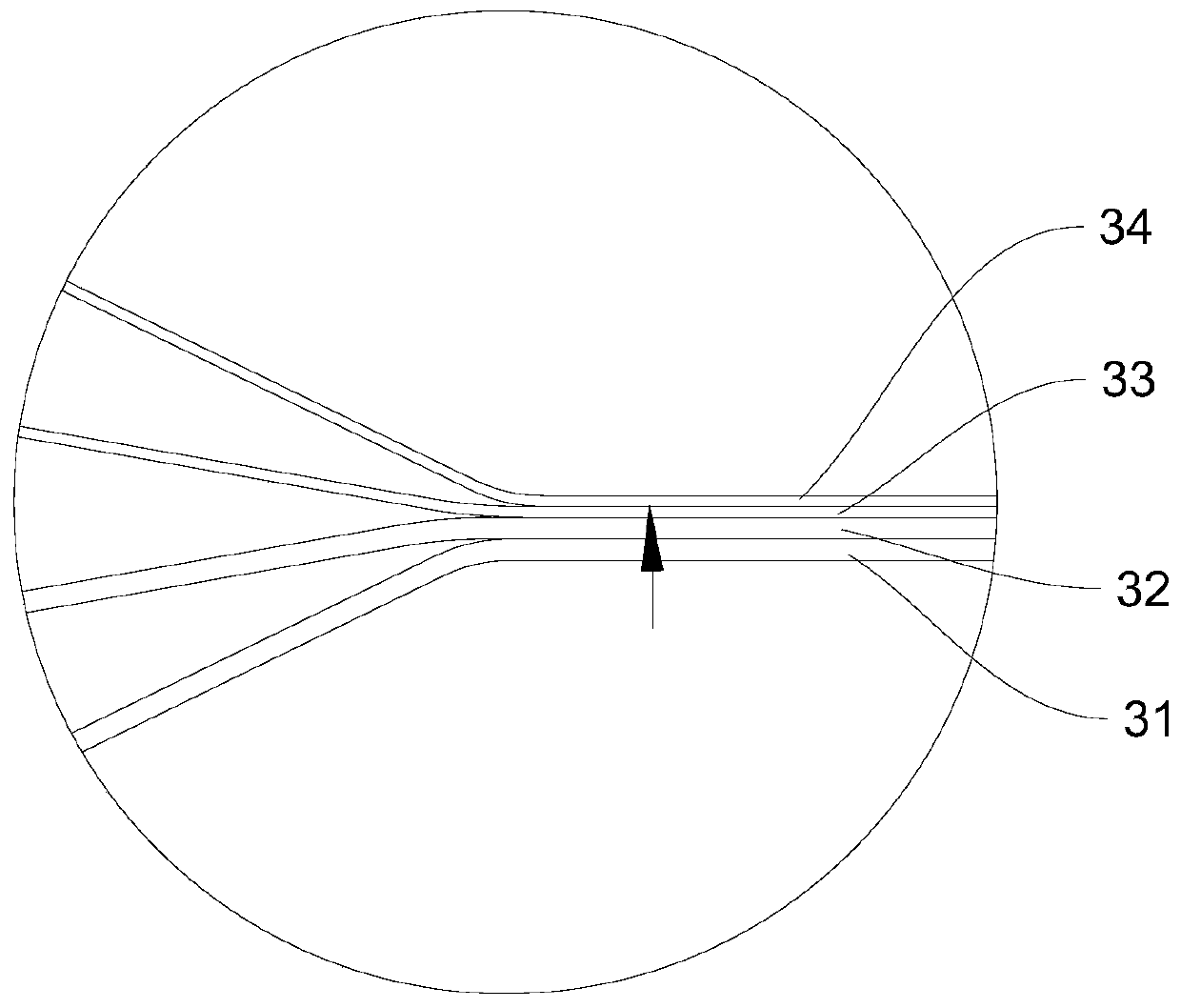

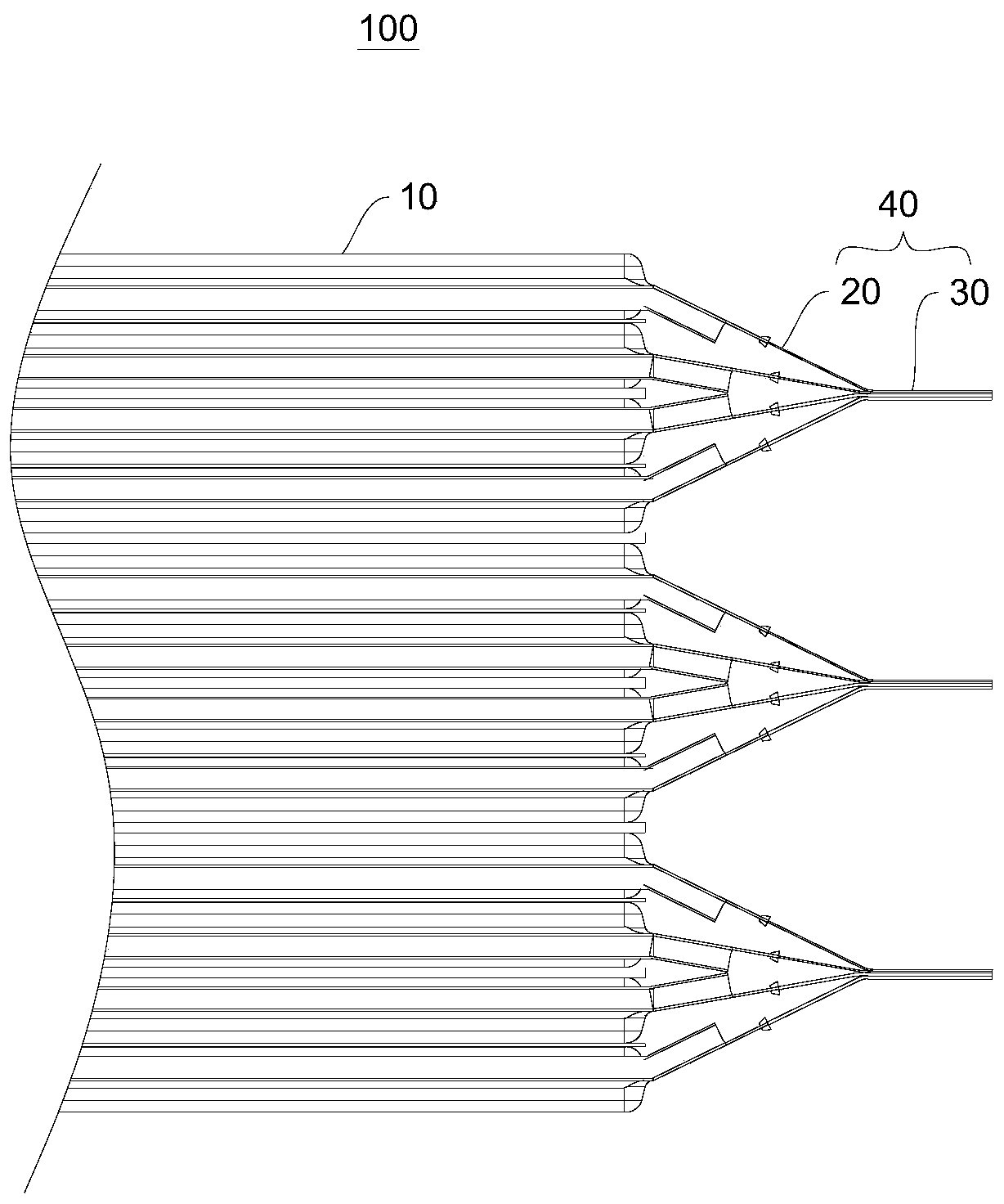

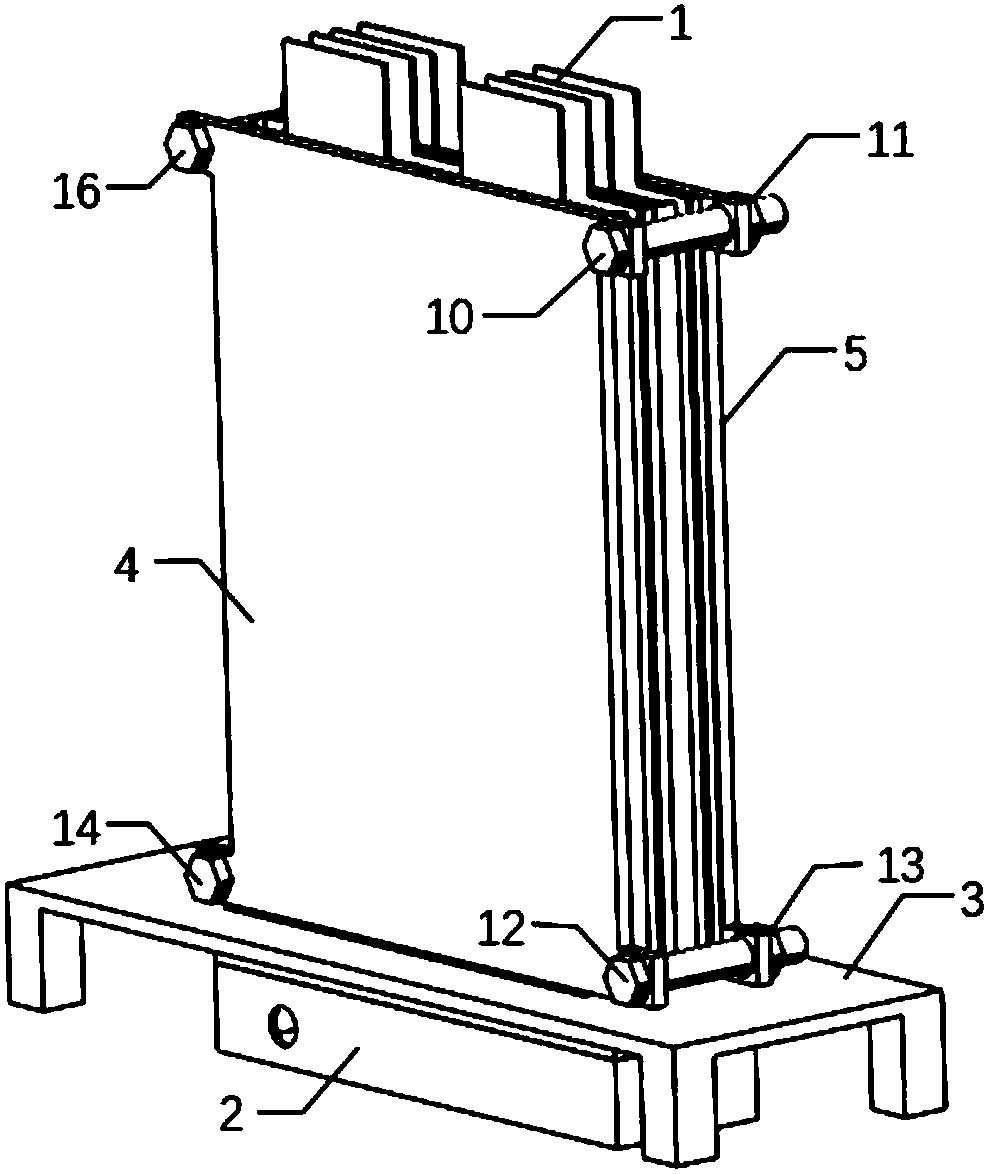

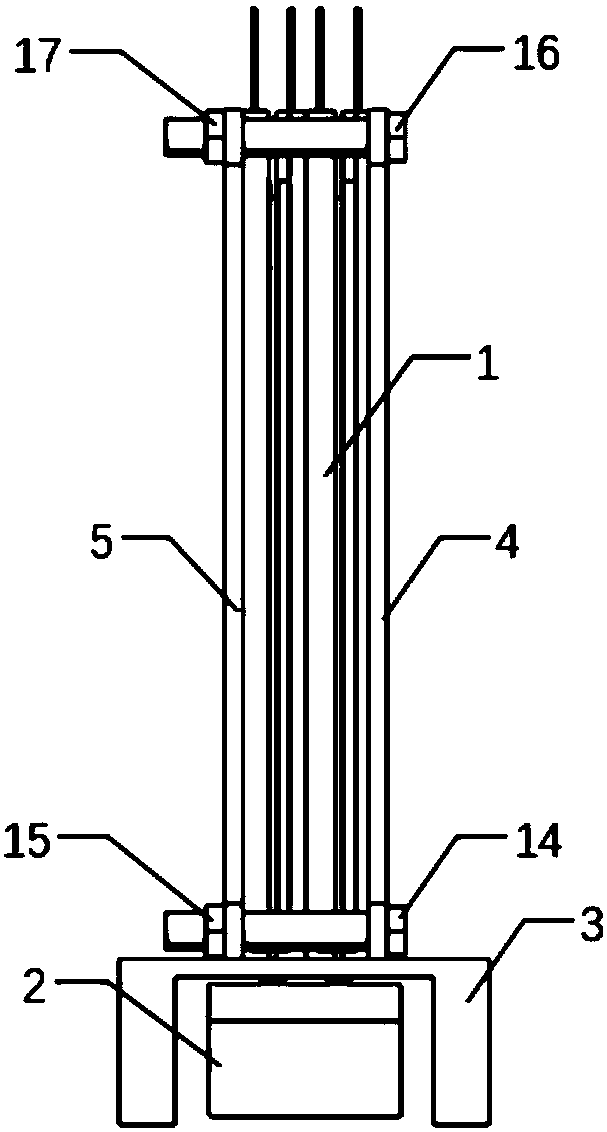

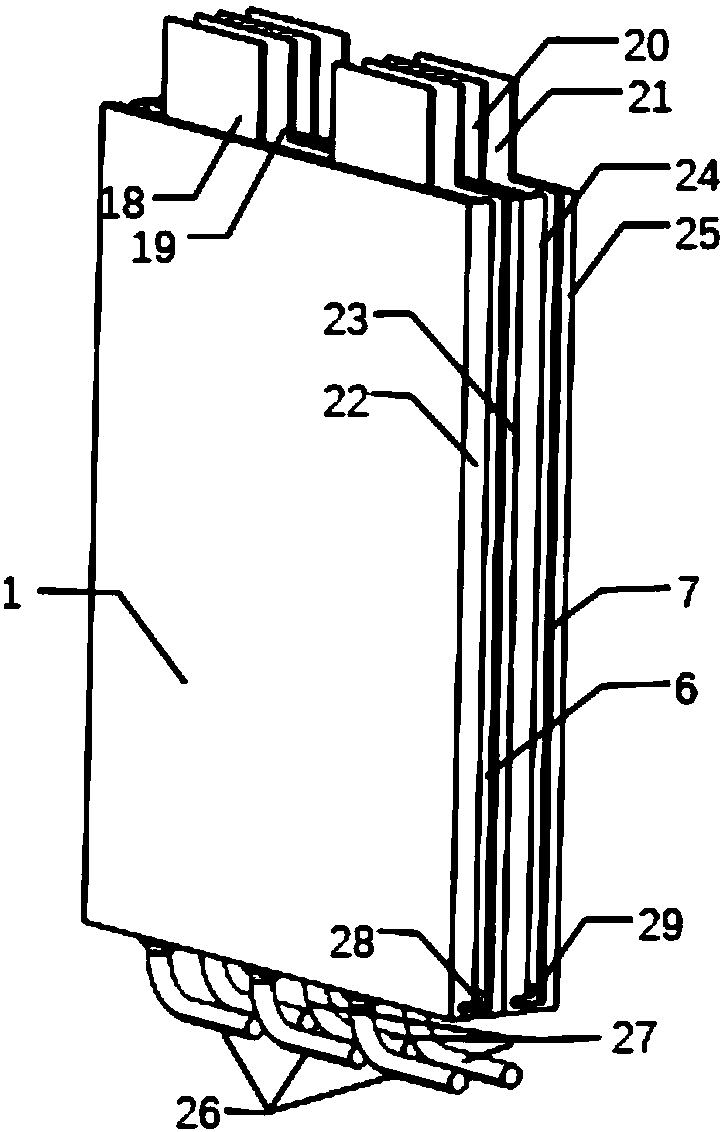

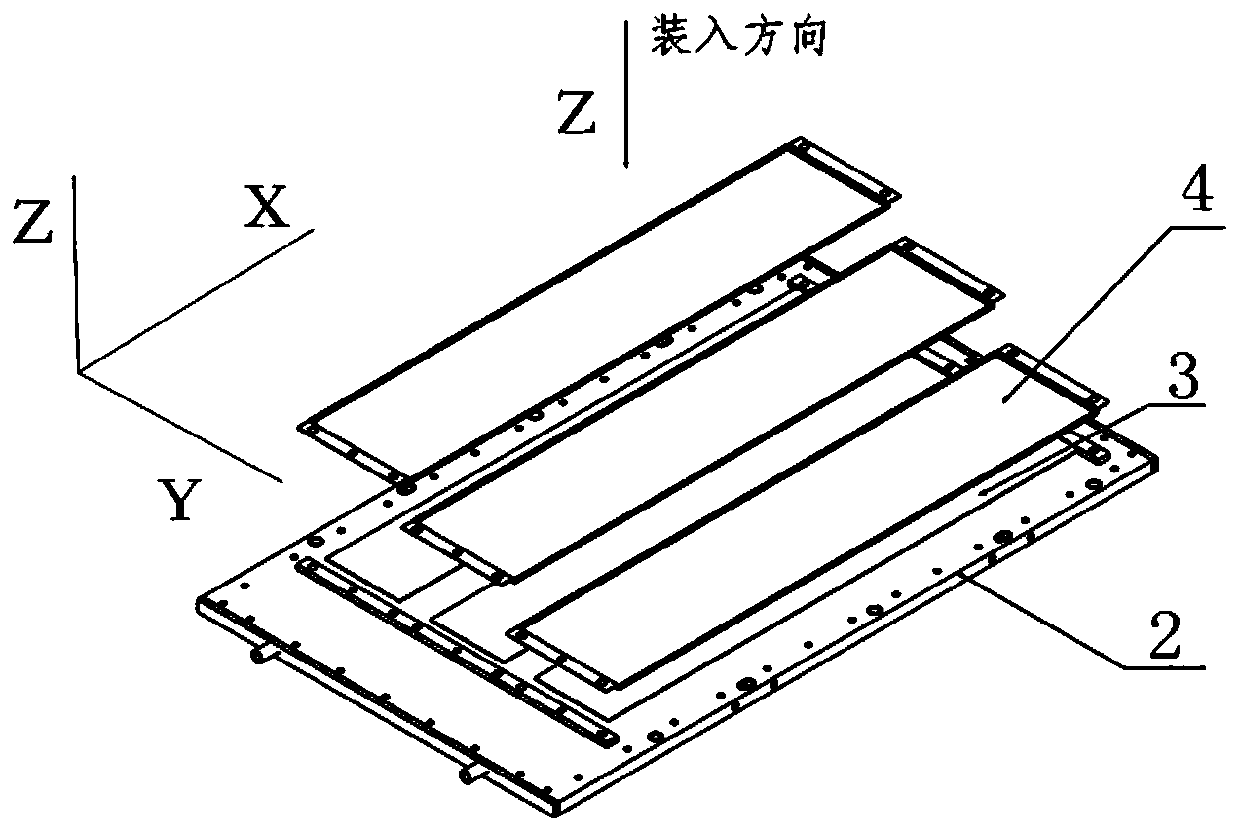

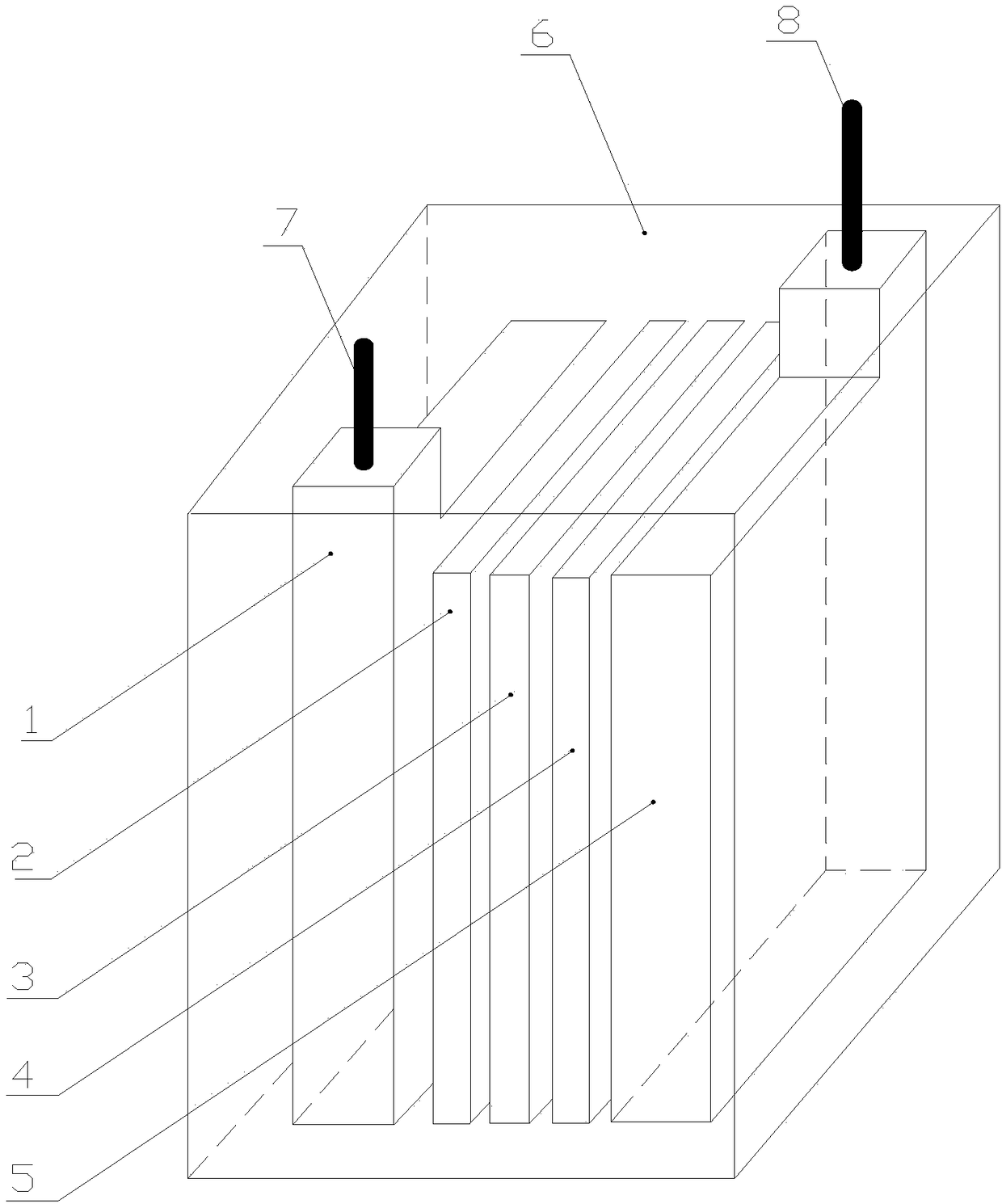

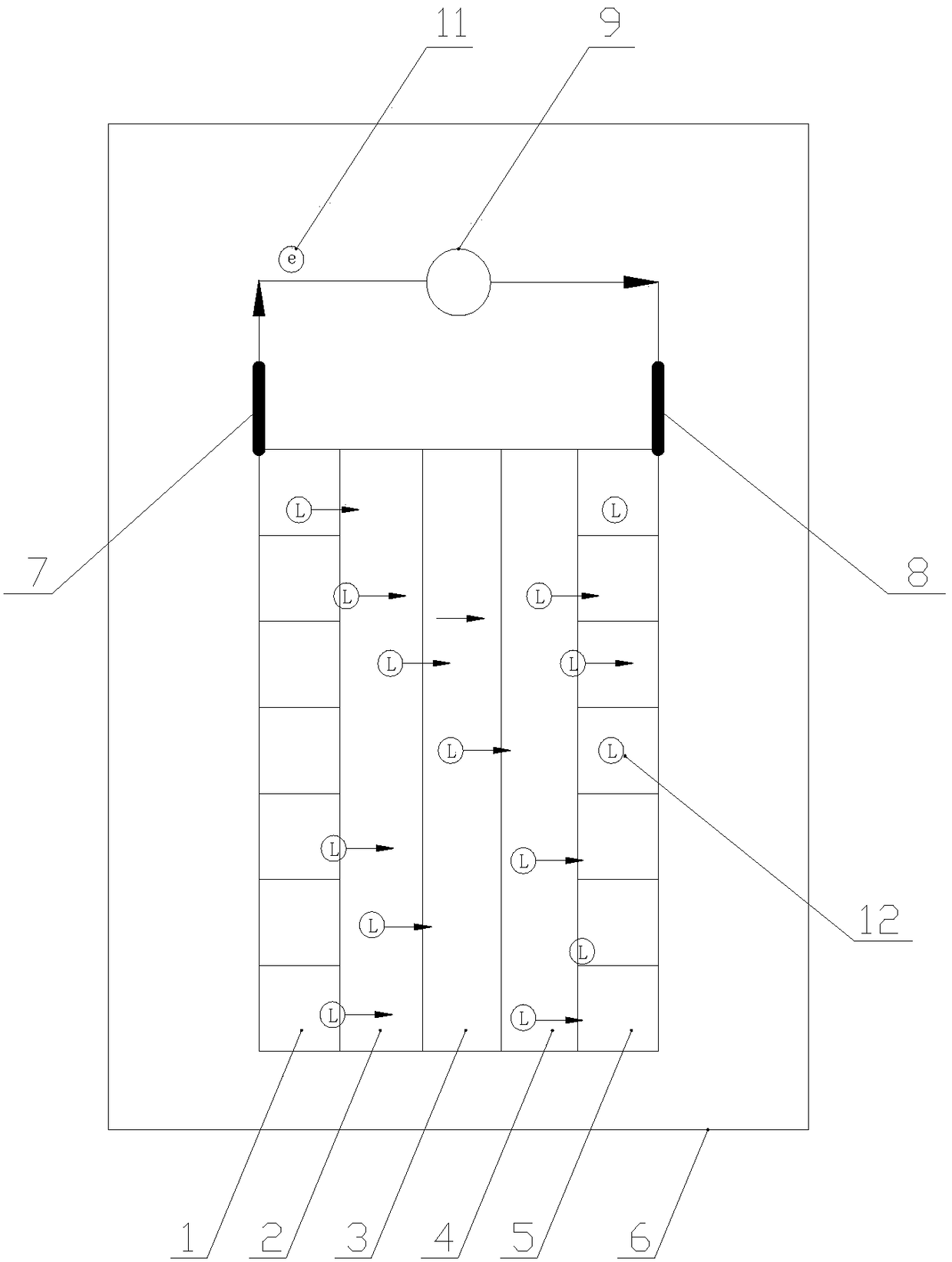

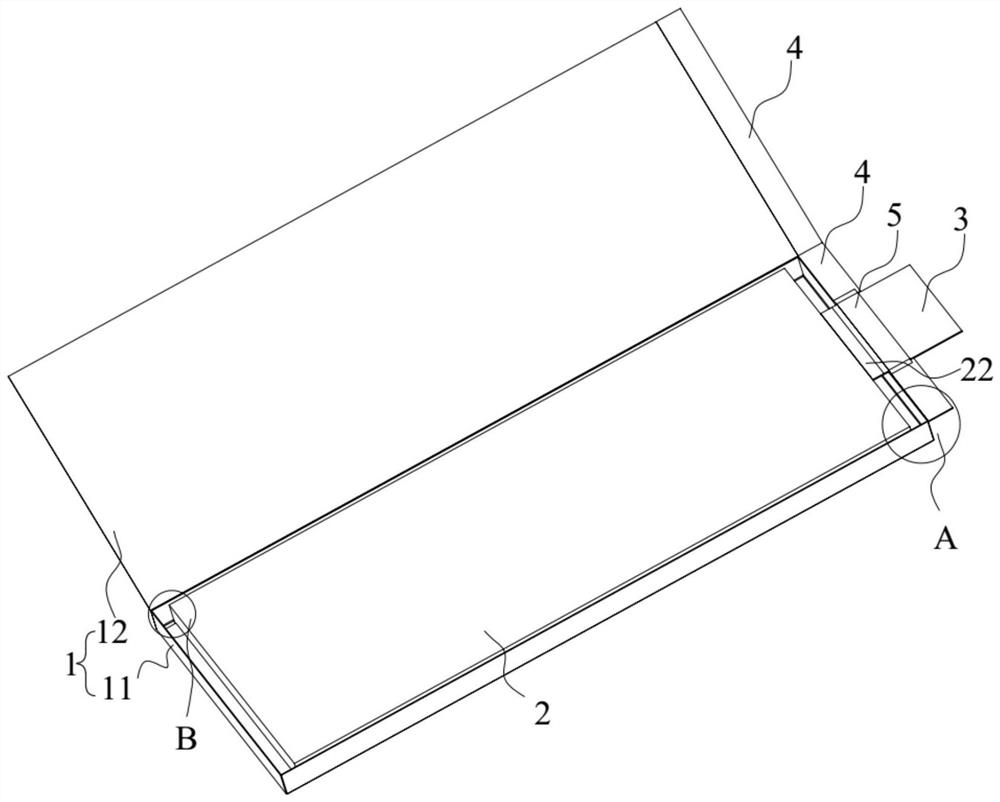

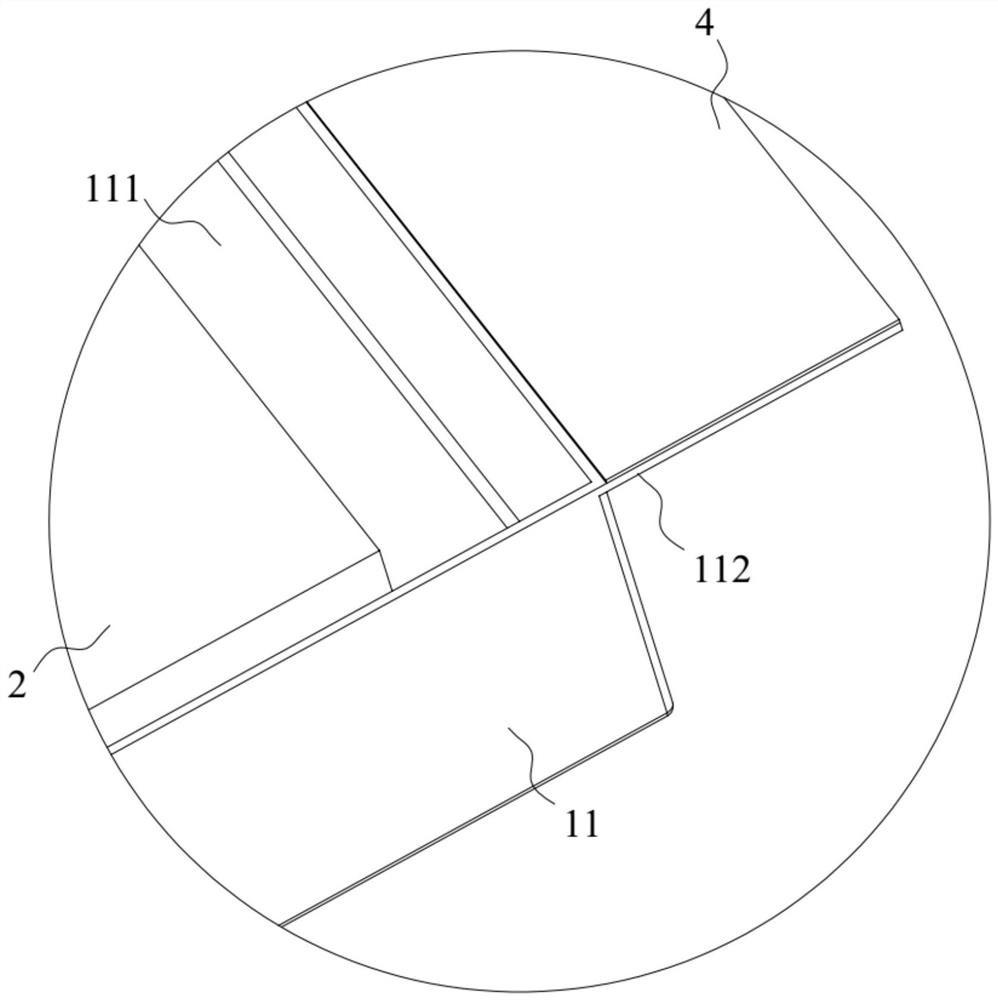

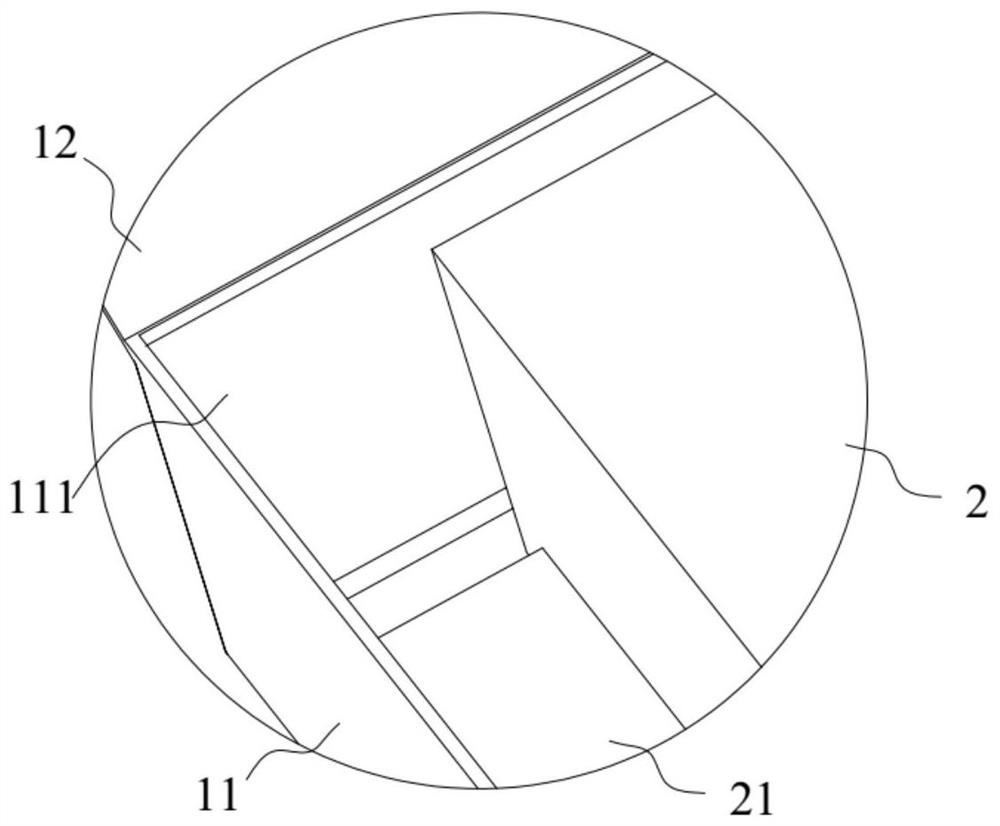

Multi-lug cell, multi-terminal battery, battery module and preparation method thereof

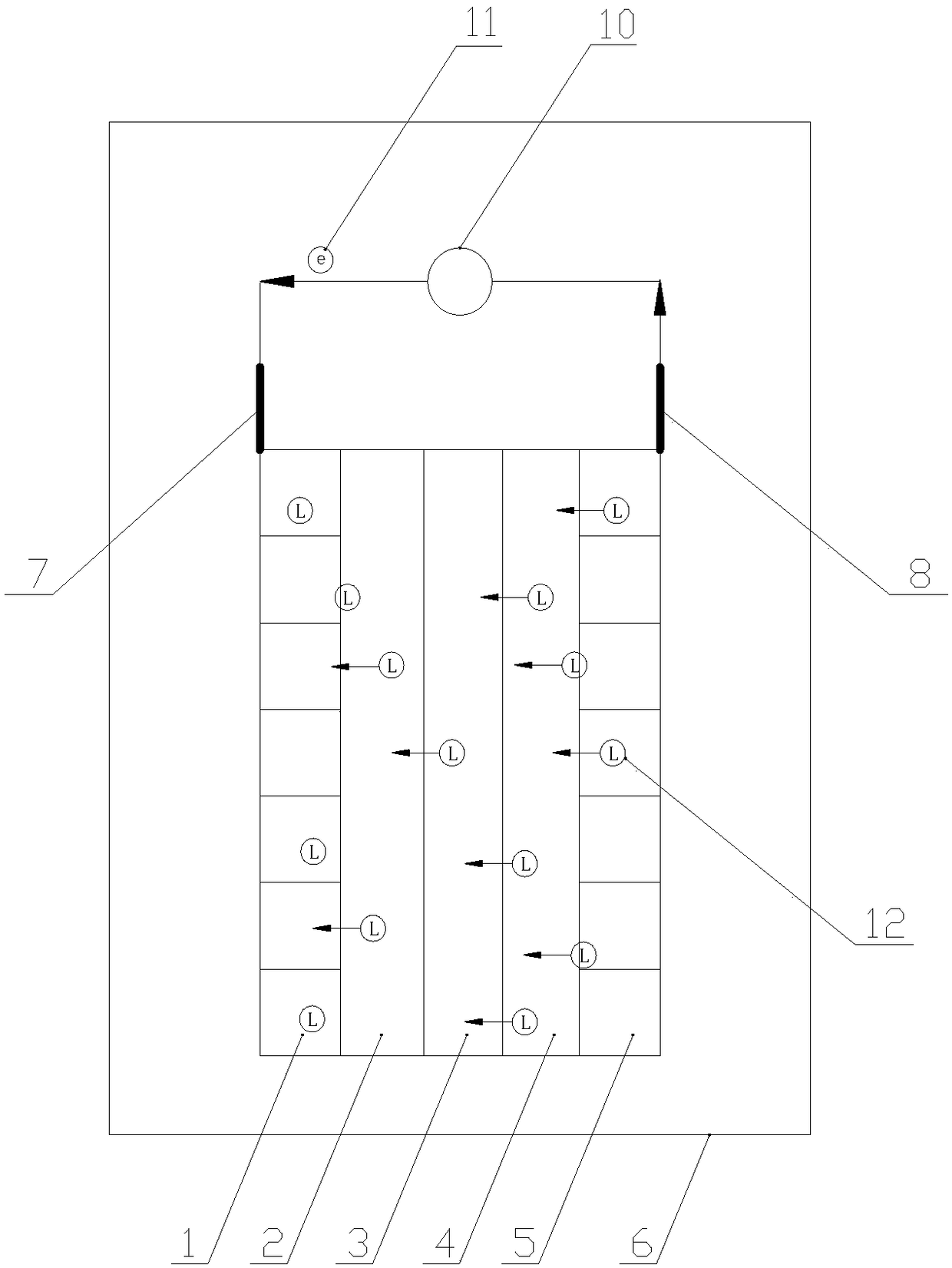

PendingCN108598354ALower internal resistanceImprove flow capacityAssembling battery machinesFinal product manufacturePower batteryInternal resistance

The invention belongs to the technical field of power batteries, in particular to a multi-lug cell. The multi-lug cell comprises a cell formed by winding or stacking a positive plate, a diaphragm anda negative plate, a plurality of corresponding positive lugs are arranged on two sides of the positive plate, and a plurality of corresponding negative lugs are arranged on two sides of the negative plate; positive lug groups on two sides of the cell are formed after the positive lugs on two sides of the positive plate are wound or stacked; and negative lug groups on two sides of the cell are formed after the negative lugs on two sides of the negative plates are wound or stacked. The lugs are arranged on two sides, and the lug groups are formed after the lugs are wound or stacked, so that theinternal resistance of the cell is reduced, the discharge capacity of the cell is strengthened, simultaneously, the thickness of the cell is further reduced, the heat dissipation capacity of the battery is improved, and the safety of the battery is strengthened. Moreover, the invention also discloses a multi-terminal battery, a battery module and a preparation method thereof.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

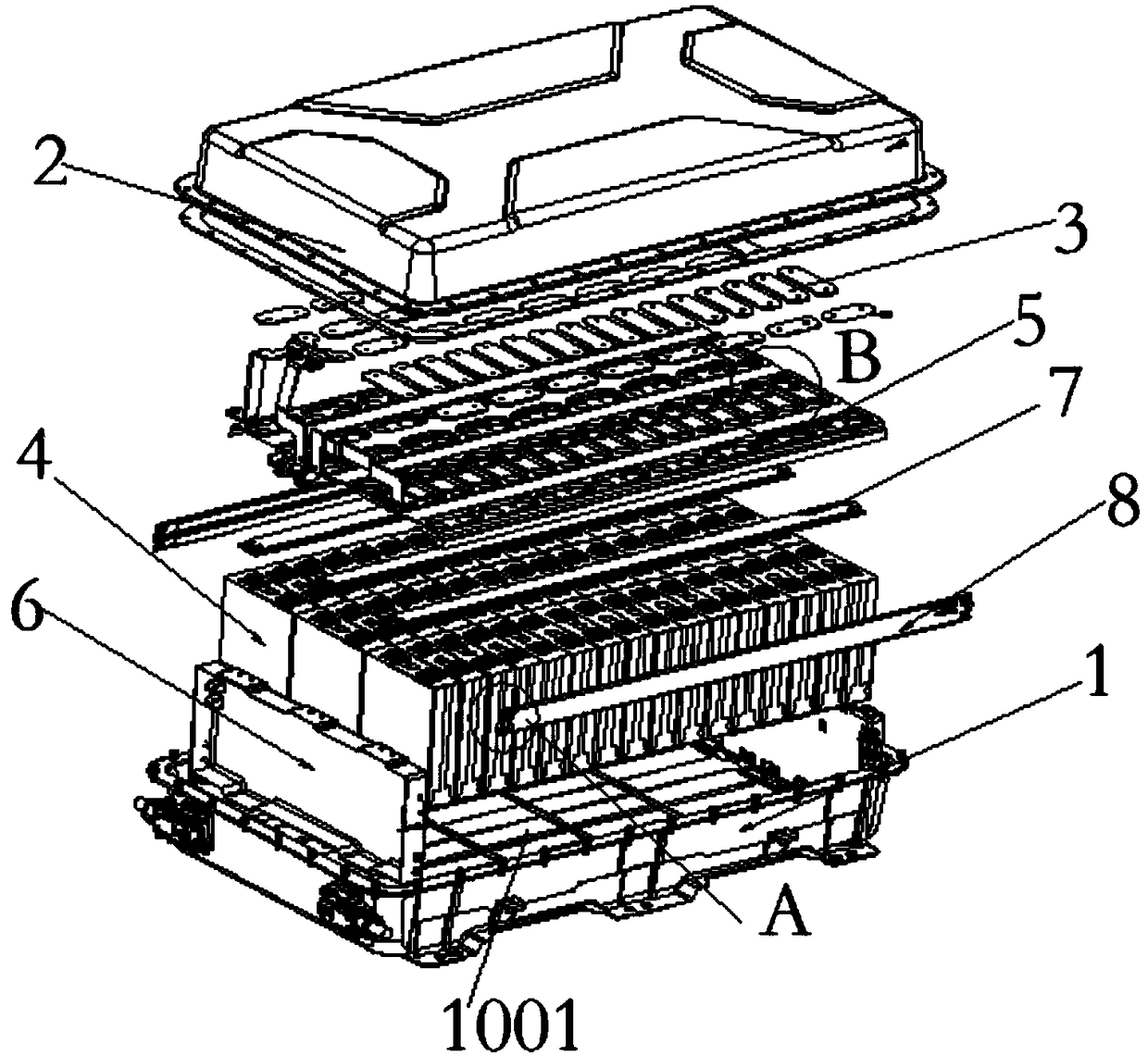

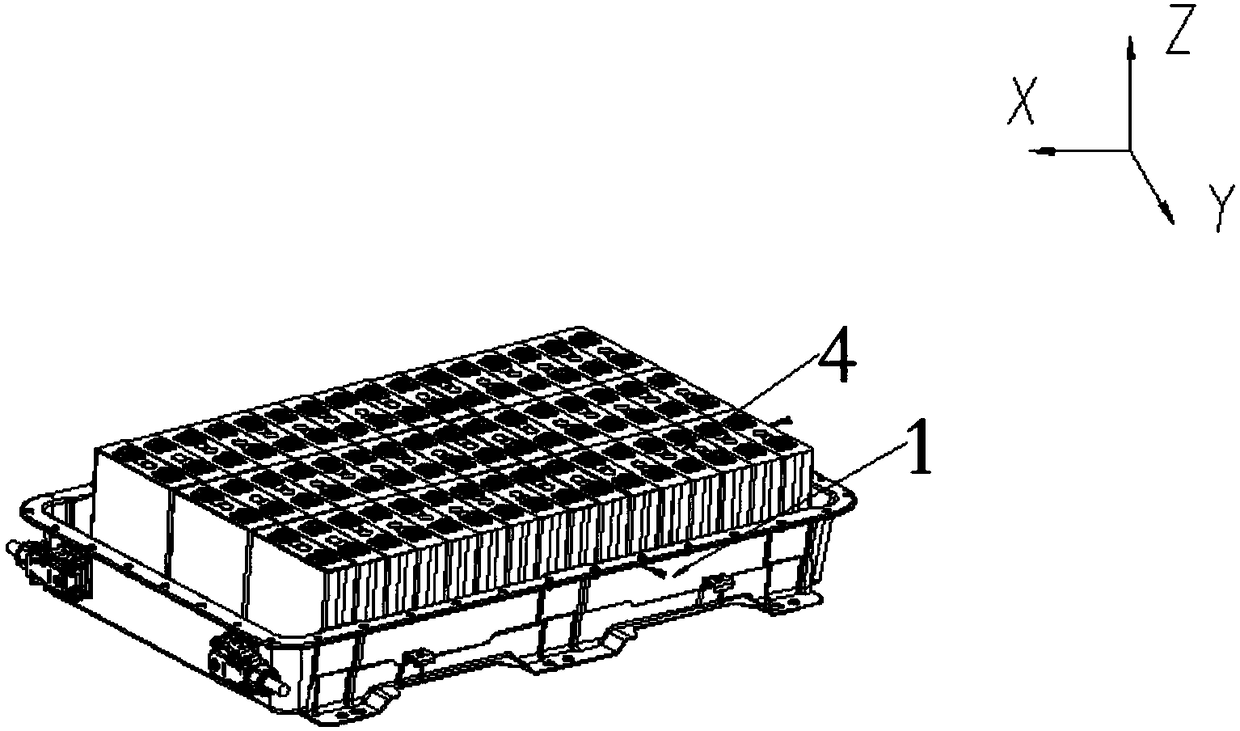

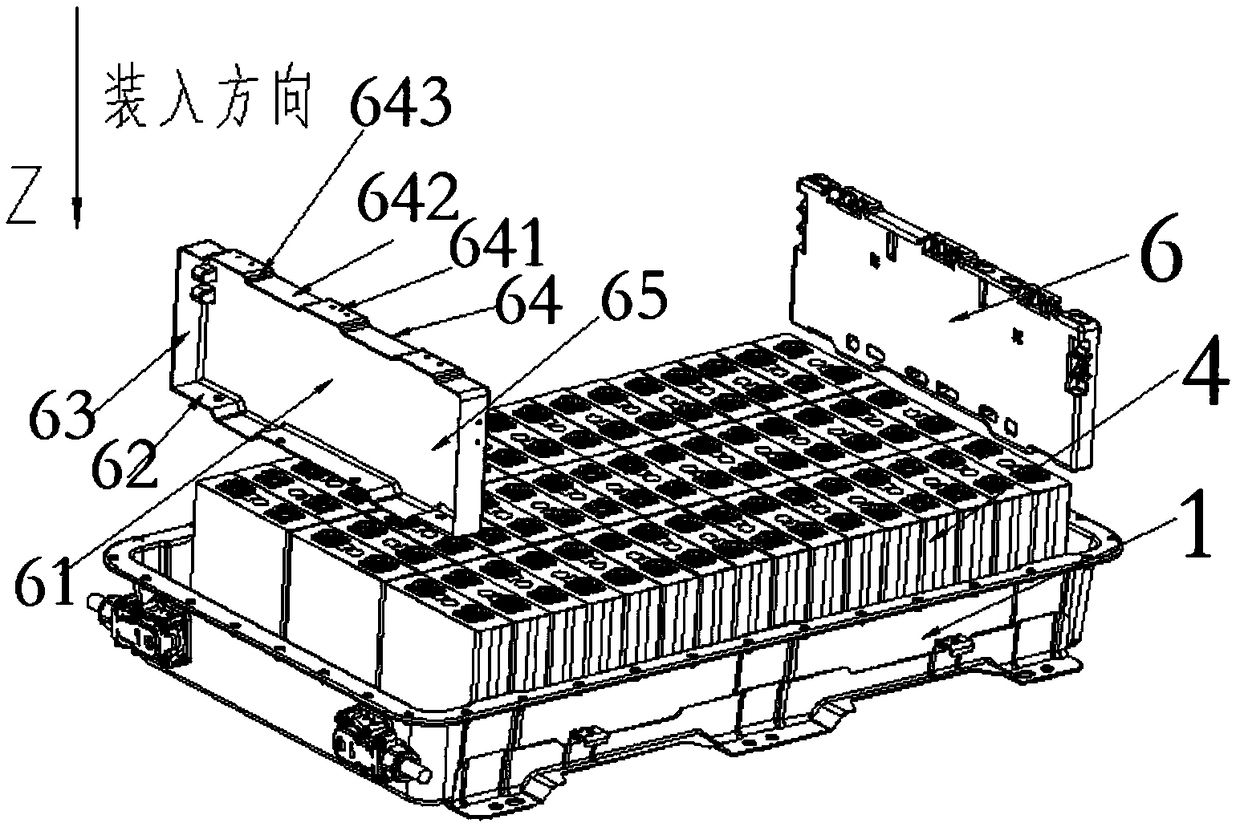

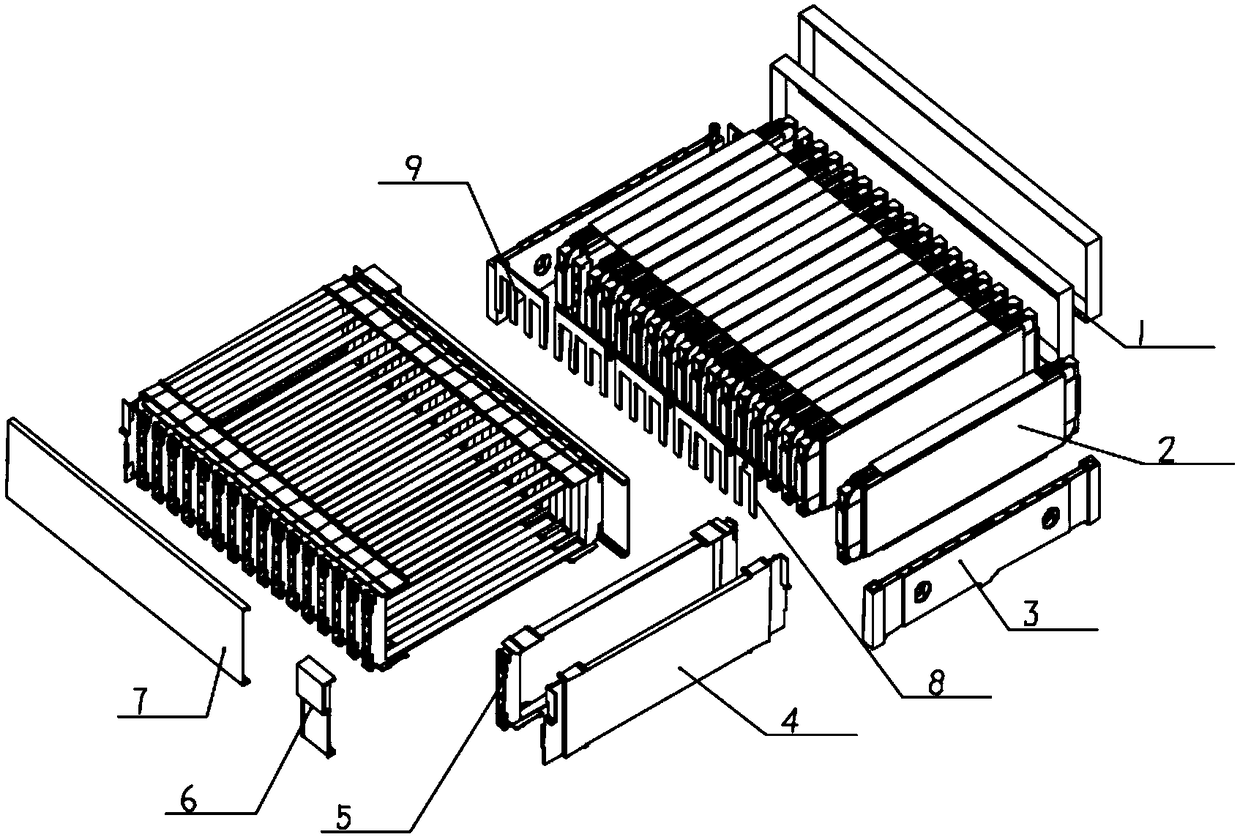

Novel power battery pack structure and assembly process thereof

InactiveCN108777268AStructural process optimizationSimple production processCurrent conducting connectionsBatteriesPower batteryElectrical battery

The invention relates to the field of power batteries, specifically to a novel power battery pack structure and an assembly process thereof. The battery pack structure comprises a box body used for placing battery cells, wherein the upper end of the box body is connected with a box cover used for protecting the battery cells arranged in the box body; a battery cell group is placed in the box bodyand comprises a plurality of battery cells; the lower end surface of each battery cell is connected with the bottom part of the box body through a structural adhesive; and the battery cells are connected through high-voltage connectors. According to a technical scheme of the invention, through improvement of traditional battery pack structures and production processes, the efficiency of group formation is high; in a traditional battery pack production process, the battery cells needs to be modularized and then assembled to form a required battery pack, while the assembly process provided by the invention omits the intermediate link of battery pack production, i.e., reduces the related production process of battery cell modularization, so the efficiency of group formation is improved; thus,the energy density of a product is improved, and the loss of energy conversion in the process of modularization is avoided.

Owner:芜湖天量电池系统有限公司

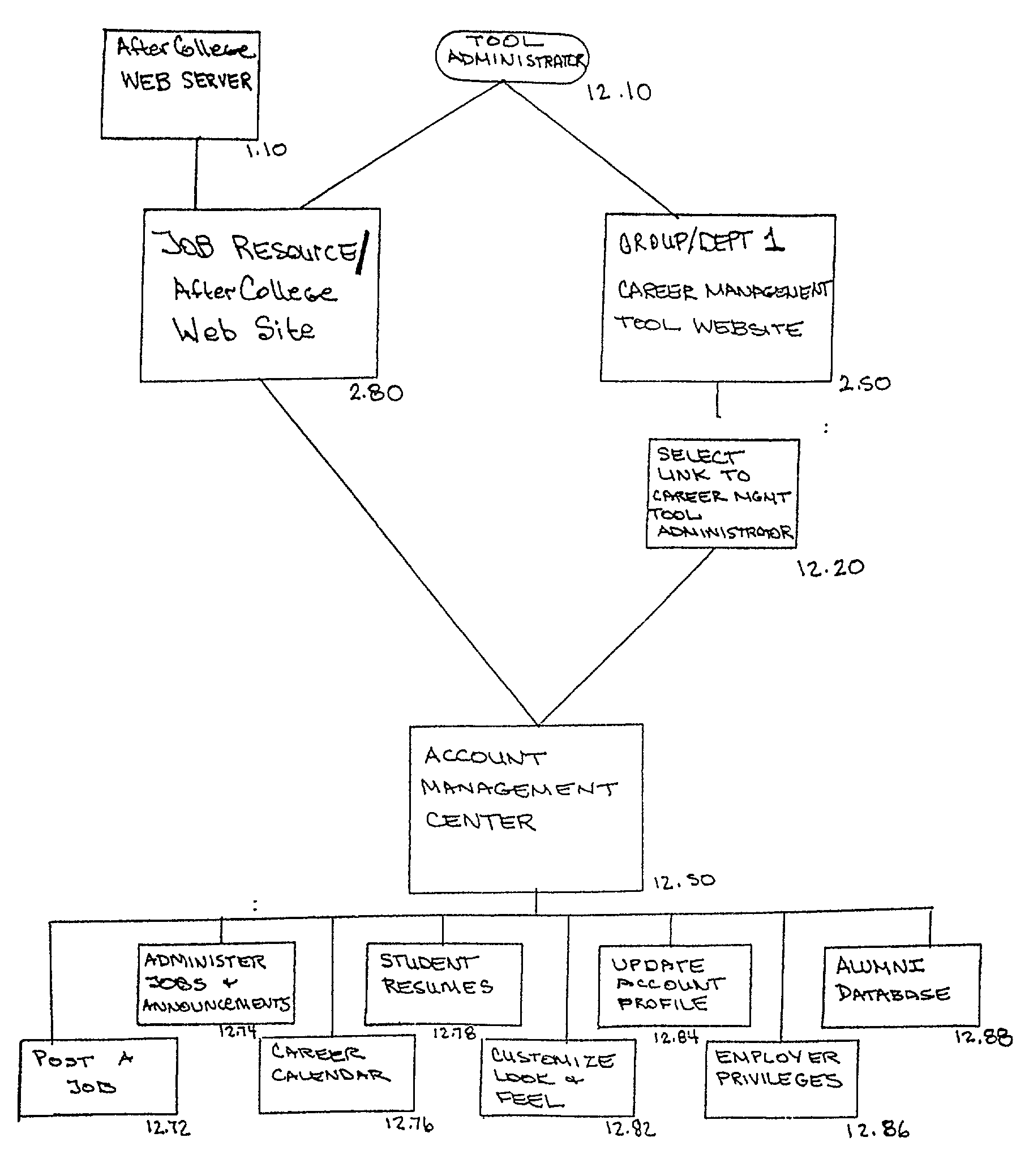

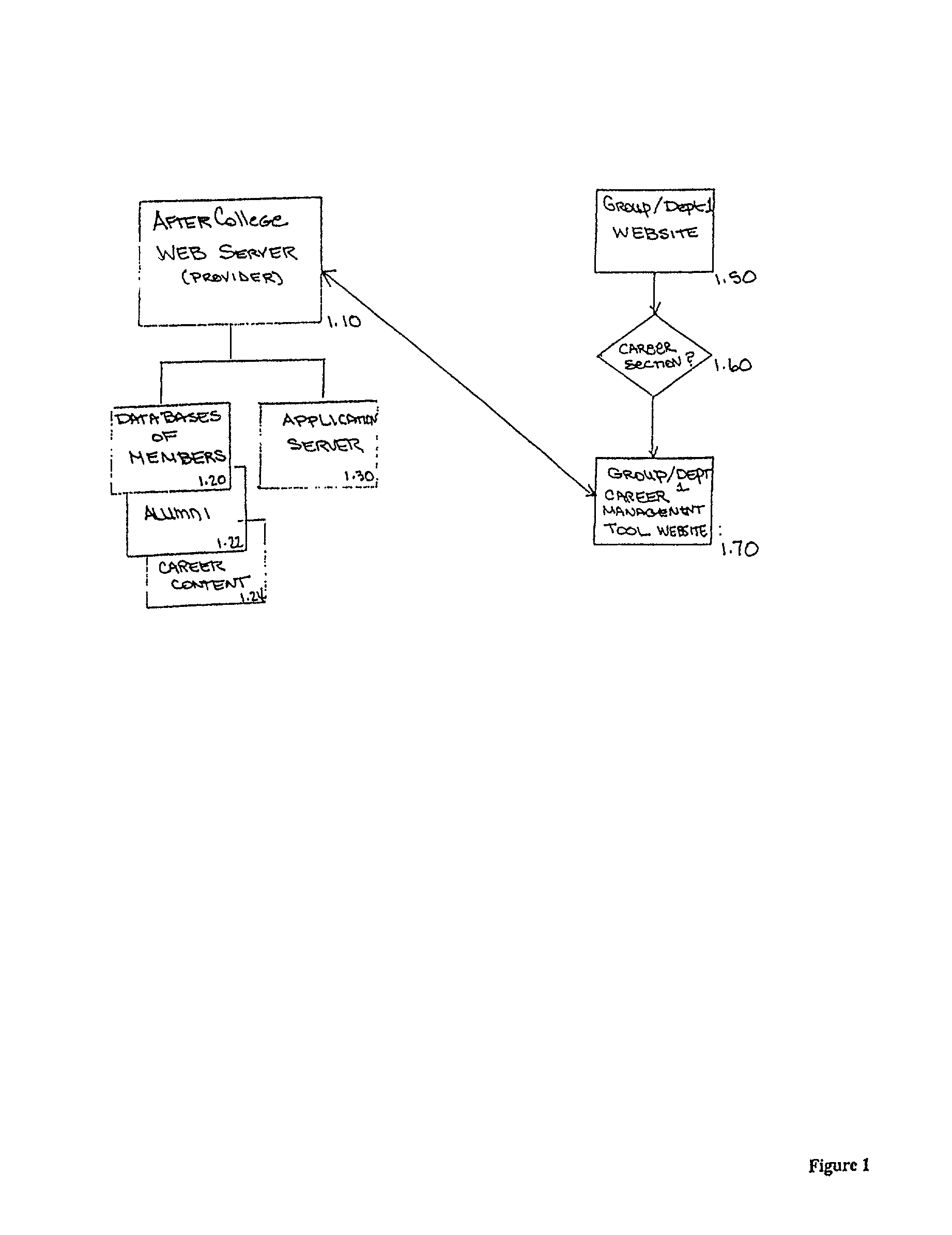

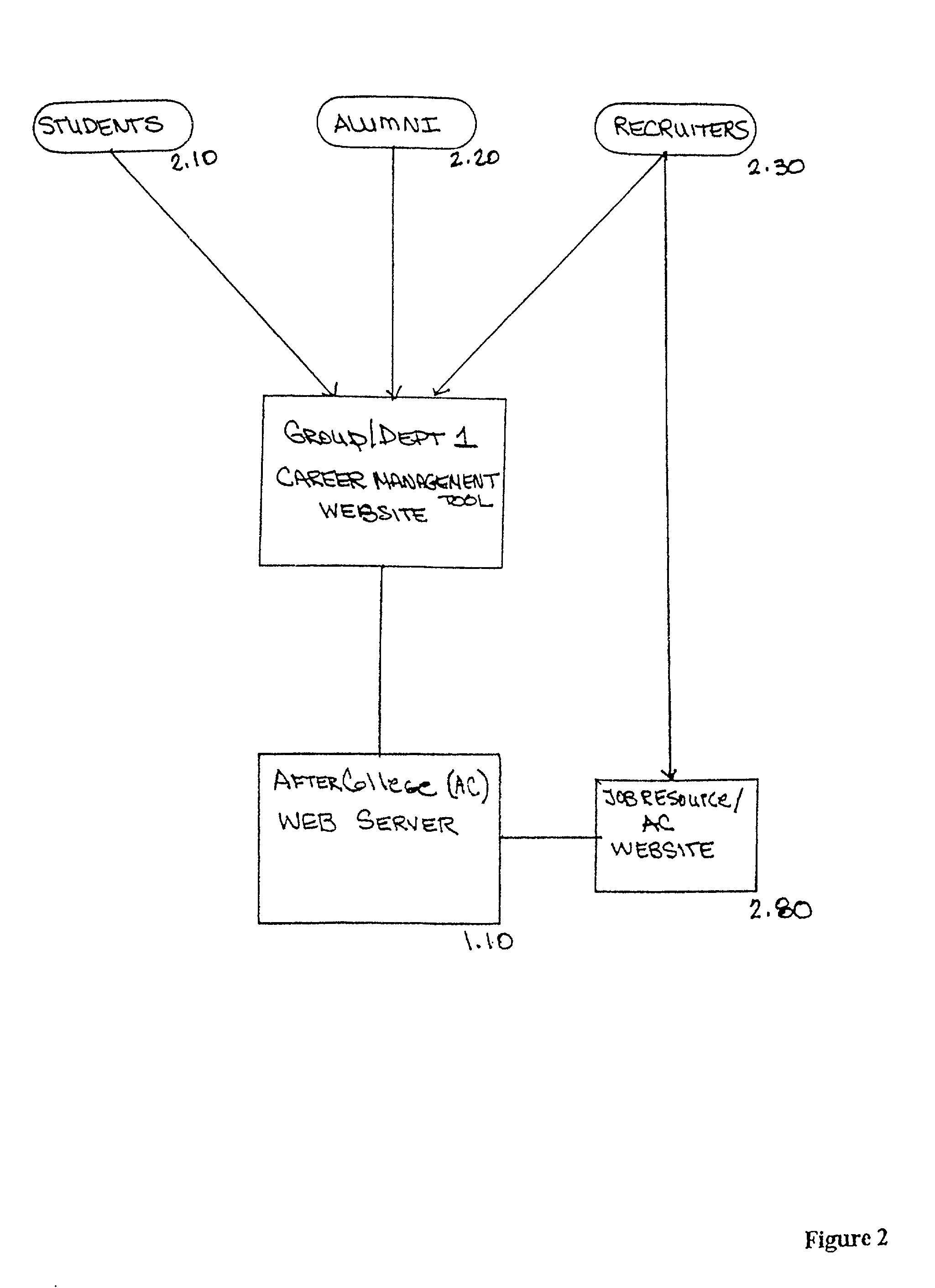

Career management tools and network

InactiveUS7213019B1Easy to implementEasy to manageCommerceSpecial data processing applicationsWeb siteManagement tool

Group-Specific “Career Management Tools” allow groups (a sample of which include: academic departments at colleges and universities, academic groups, campus fraternity chapters, professional group chapters, and any cluster of individuals that identifies itself as a group), to manage their career-related activity on-line, through a tool containing functionality that includes, but is not limited to: a group-specific resume database, a group-specific job database, and a group-specific alumni database. Career Management Tools provide career-related information for group members, and such information is targeted specifically to the group. Information is entered into the Career Management Tool by group members (such as students, faculty, department administrators, group officers, and alumni), or by entities trying to target group members. Career Management Tools are deployed on a group's web site, and are branded to the group site's look and feel and they are accessible from the group's web site.

Owner:AFTERCOLLEGE

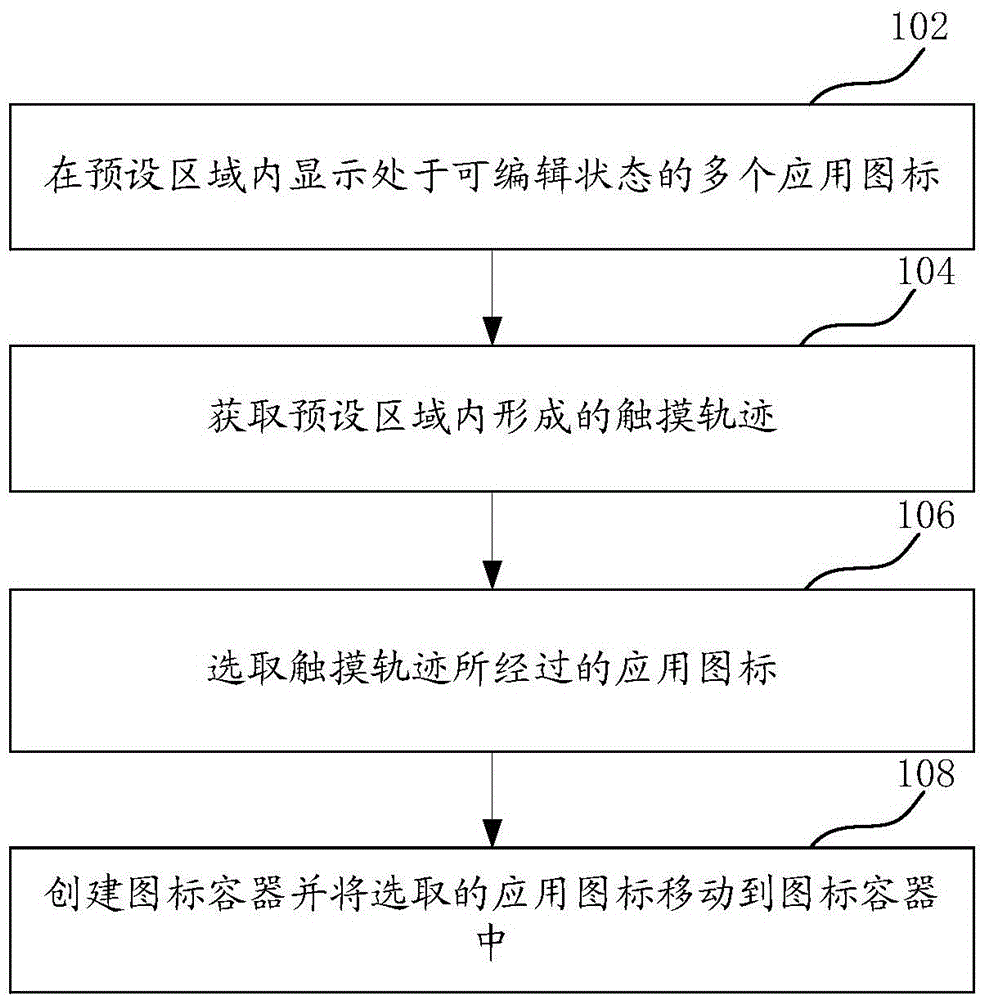

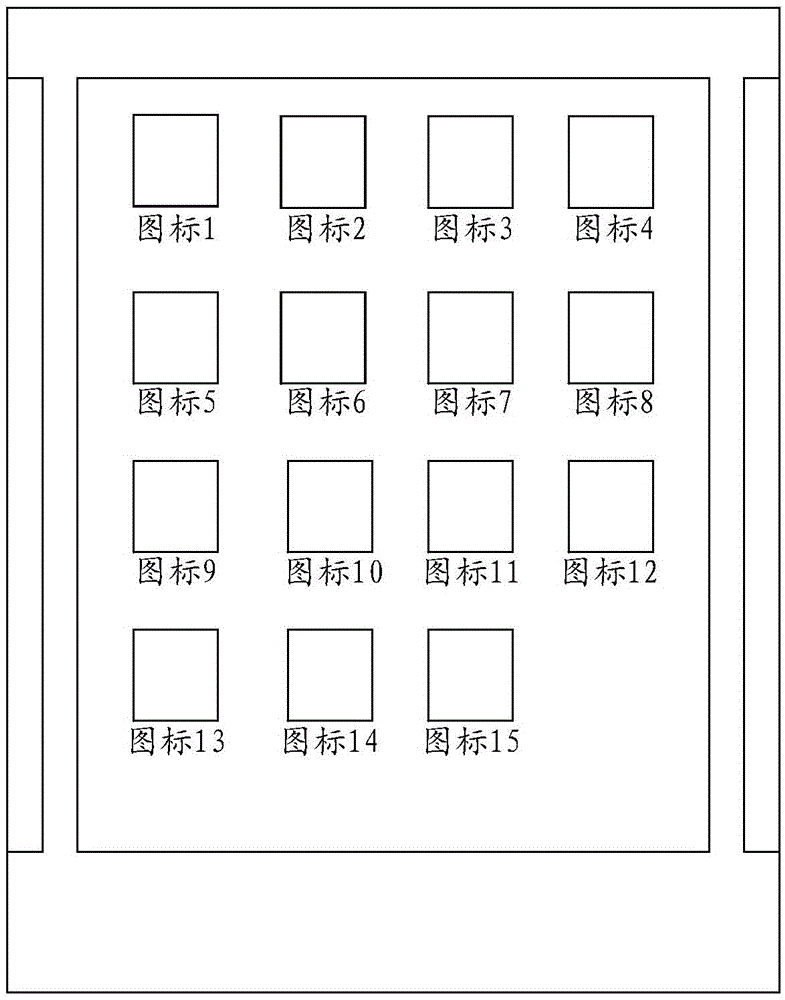

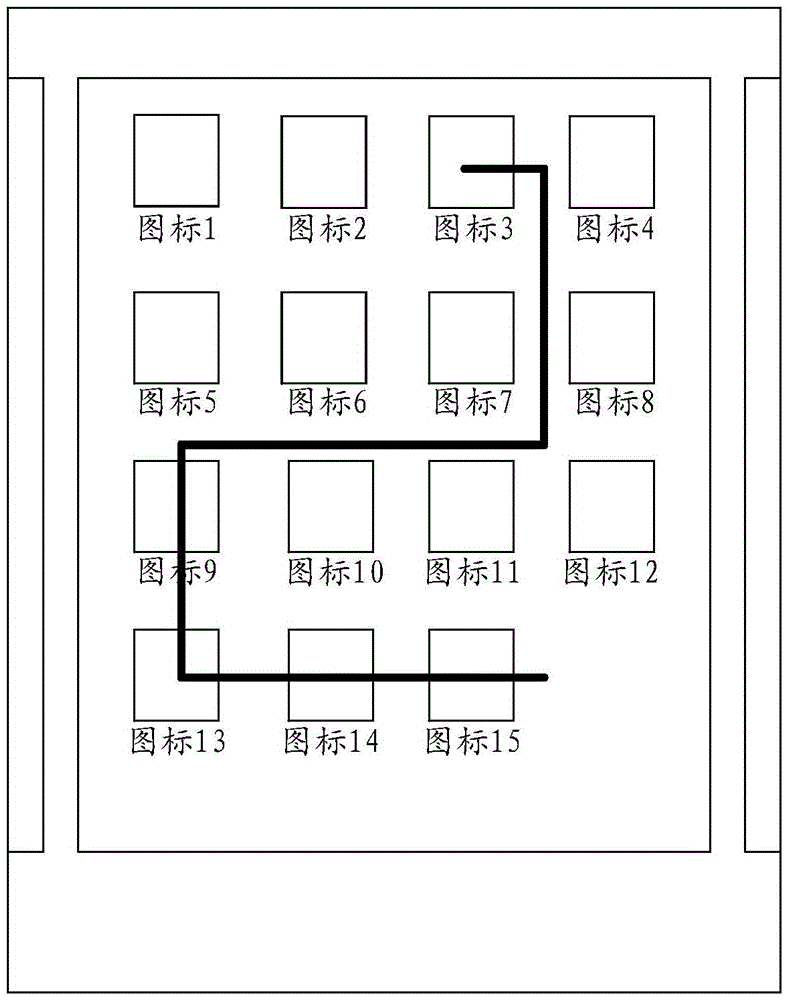

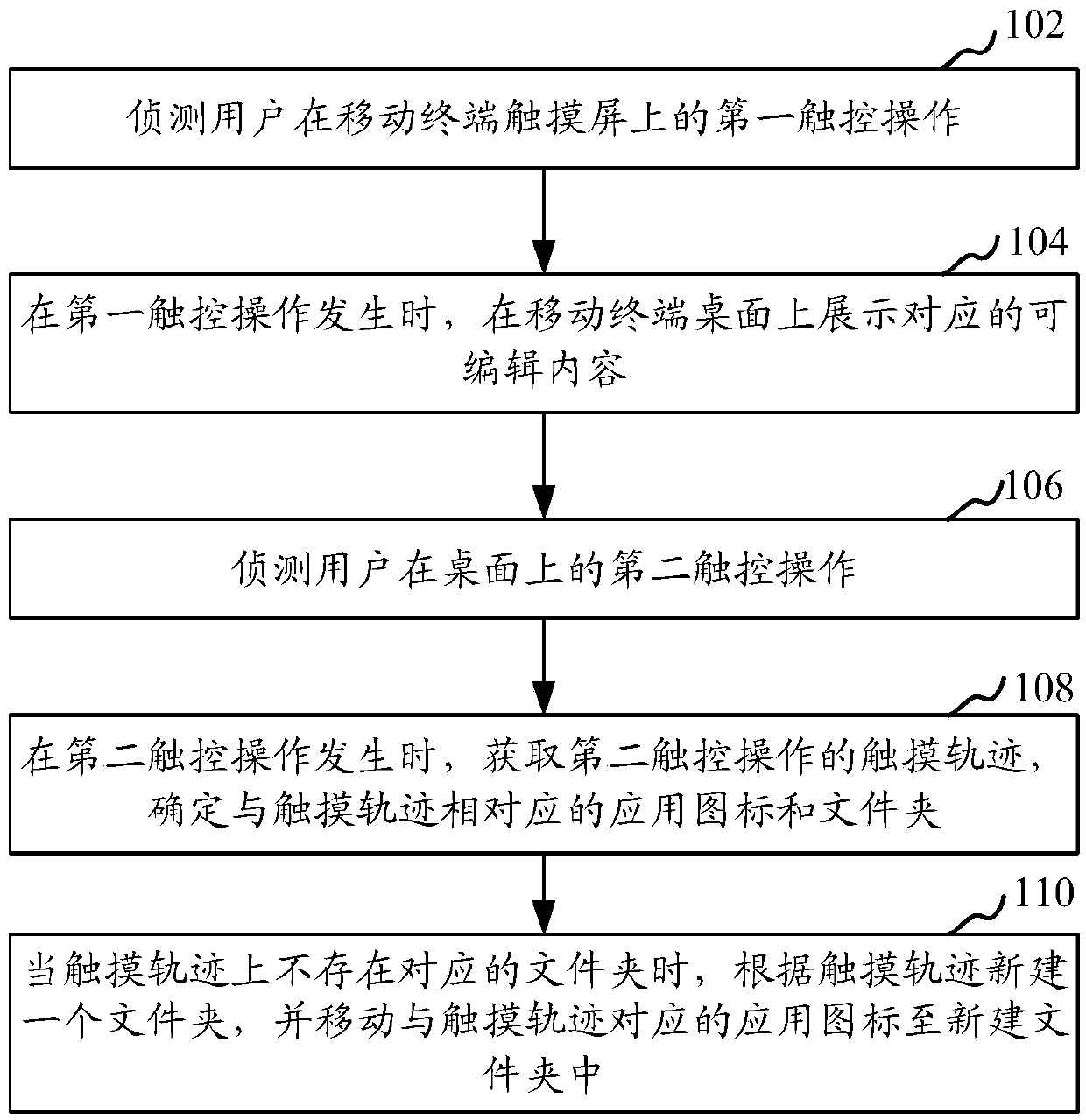

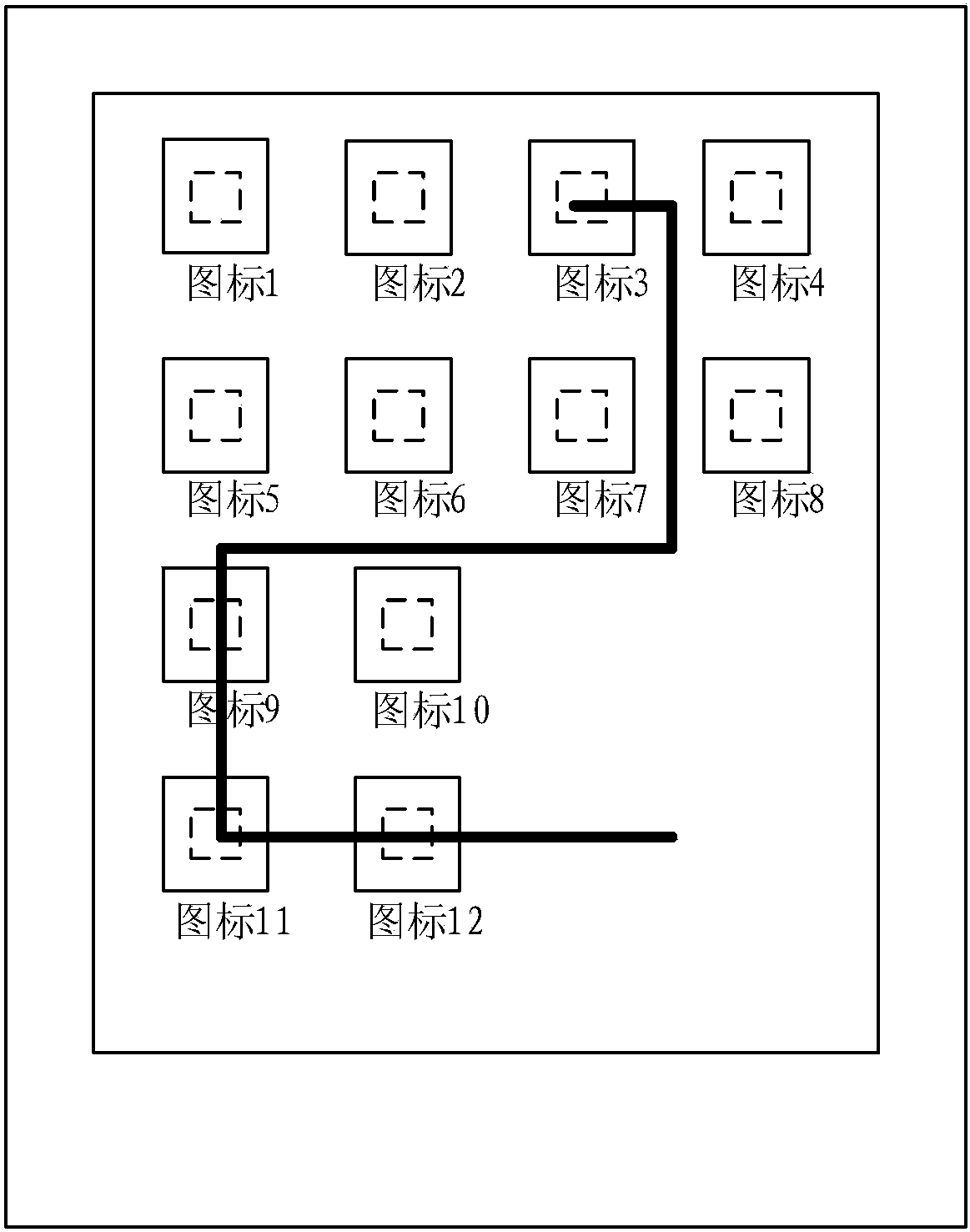

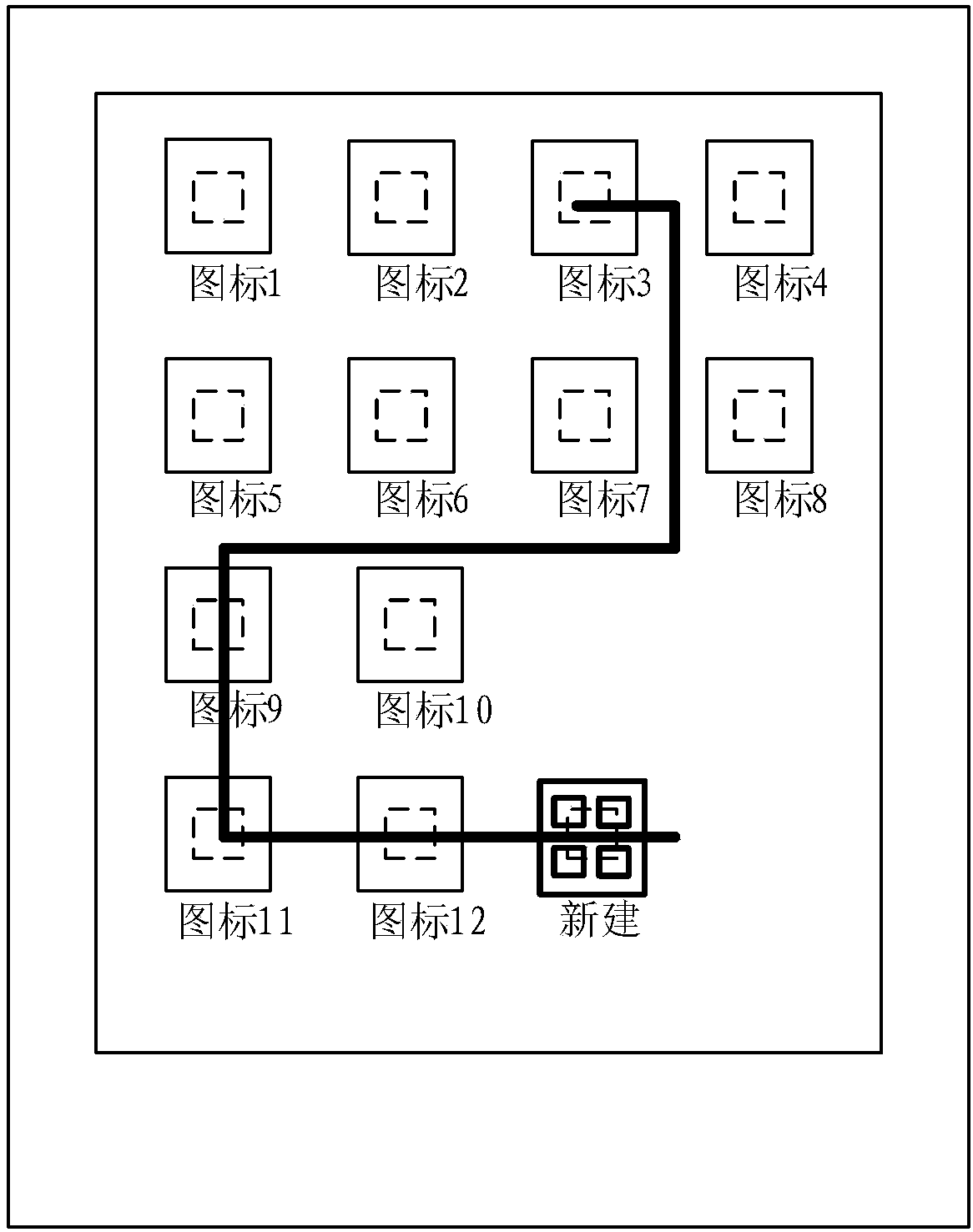

Management method and device of application icon

InactiveCN105630288ASolve the cumbersomeImprove group efficiencyInput/output processes for data processingComplex problemsGroup efficiency

Owner:深圳市慧动创想科技有限公司

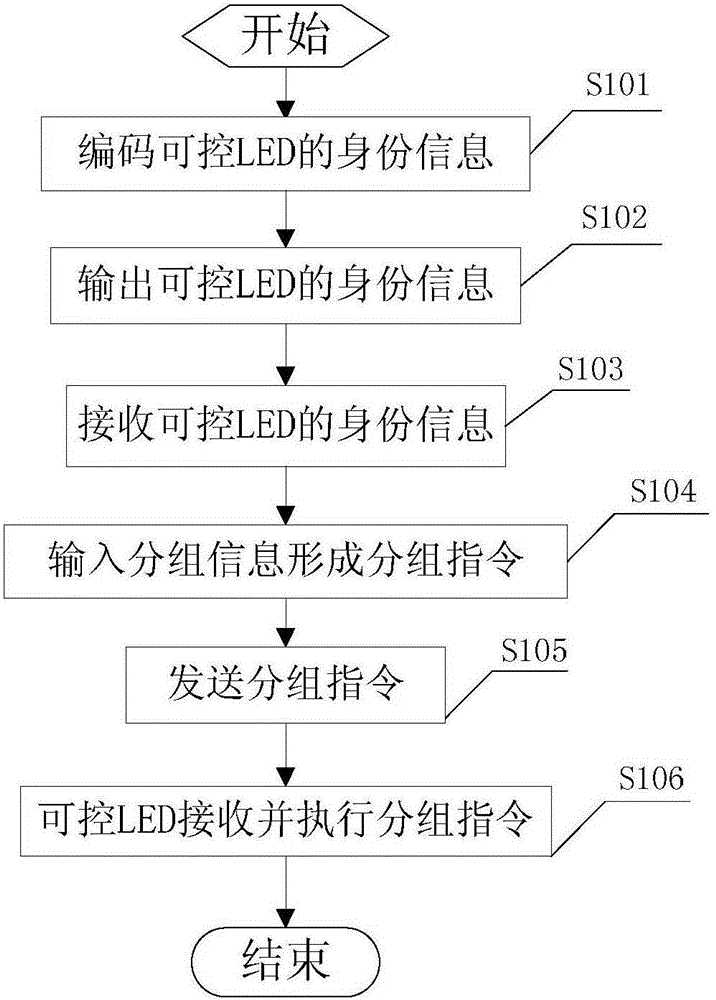

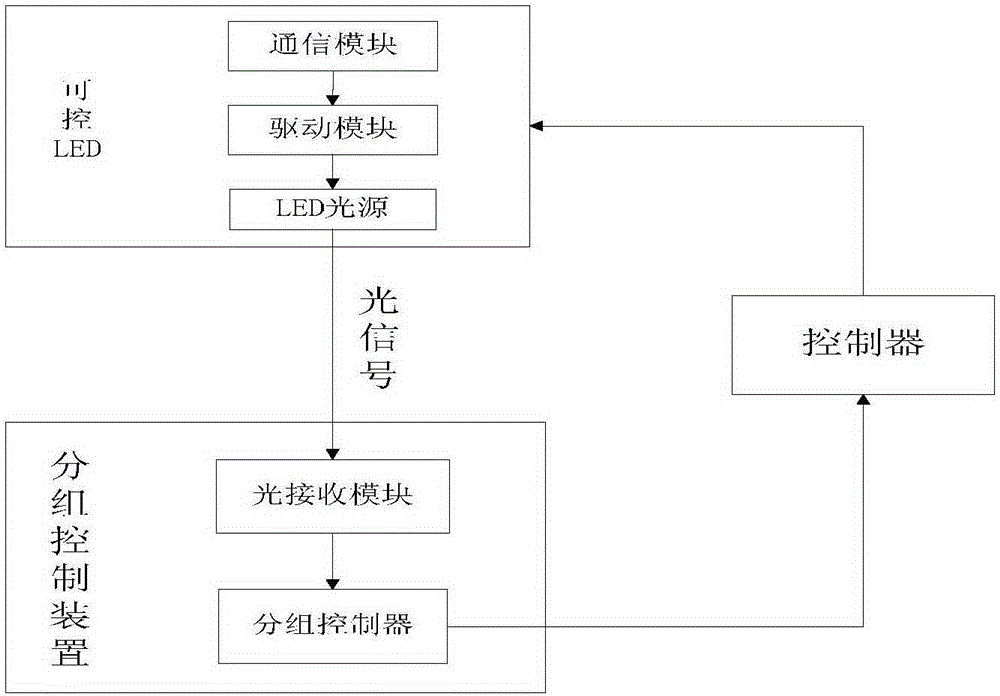

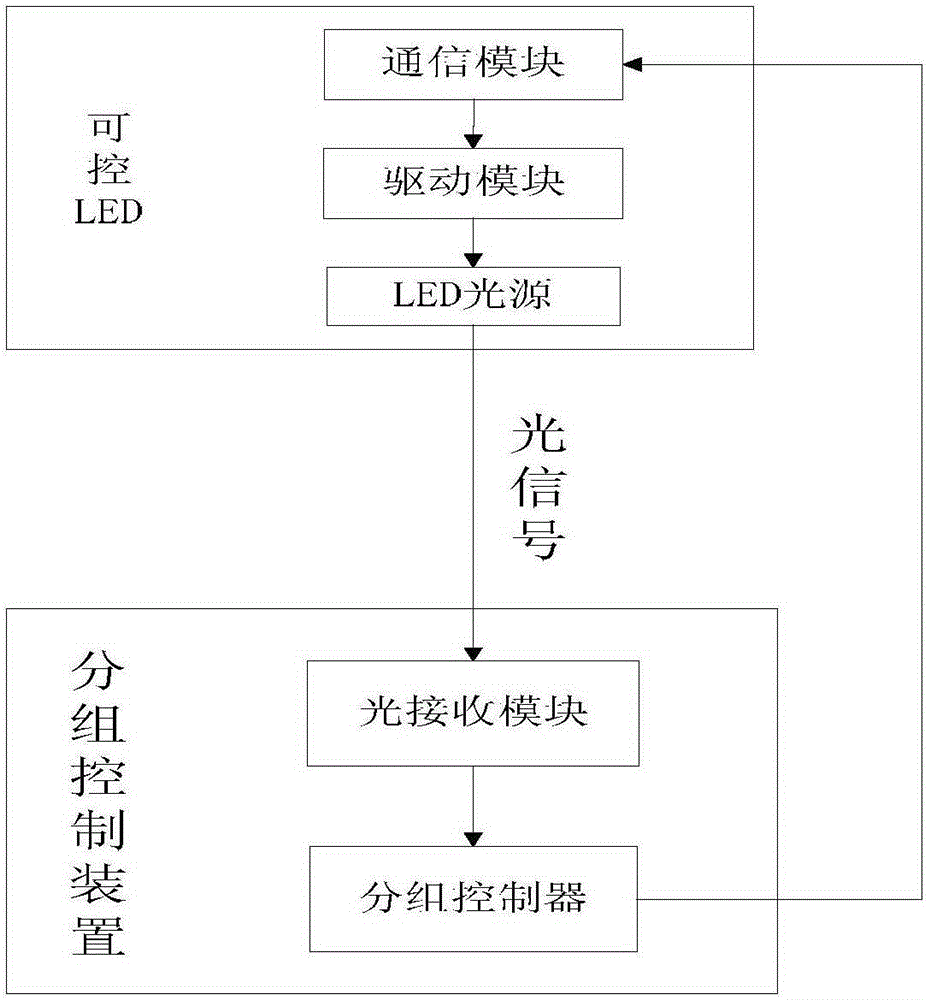

Grouping control method and system of controllable LED

ActiveCN105208715AGroup quicklyImprove grouping efficiencyElectric light circuit arrangementGroup methodData mining

The invention provides a grouping control method and system of controllable LED. The method comprises that b) a grouping request is initiated, each LED is triggered to flicker, and flickering rules of the LED differ from one another; c) identity information of the LED to be grouped is identified according to the received flickering rule of the LED to be grouped; d) a grouping instruction is sent to the LED to be grouped; and 3) the LED to be grouped receives and executes the grouping instruction, and grouping is completed. According to the method and system, grouping is rapid, the grouping method of the controllable LED is simplified, the method and system satisfy operation habits of users more, the requirement of grouping control for the controllable LED is met, and the method and system can be applied to different occasions and can be widely popularized.

Owner:HEUVAN CHONGQING SCI TECH CO LTD

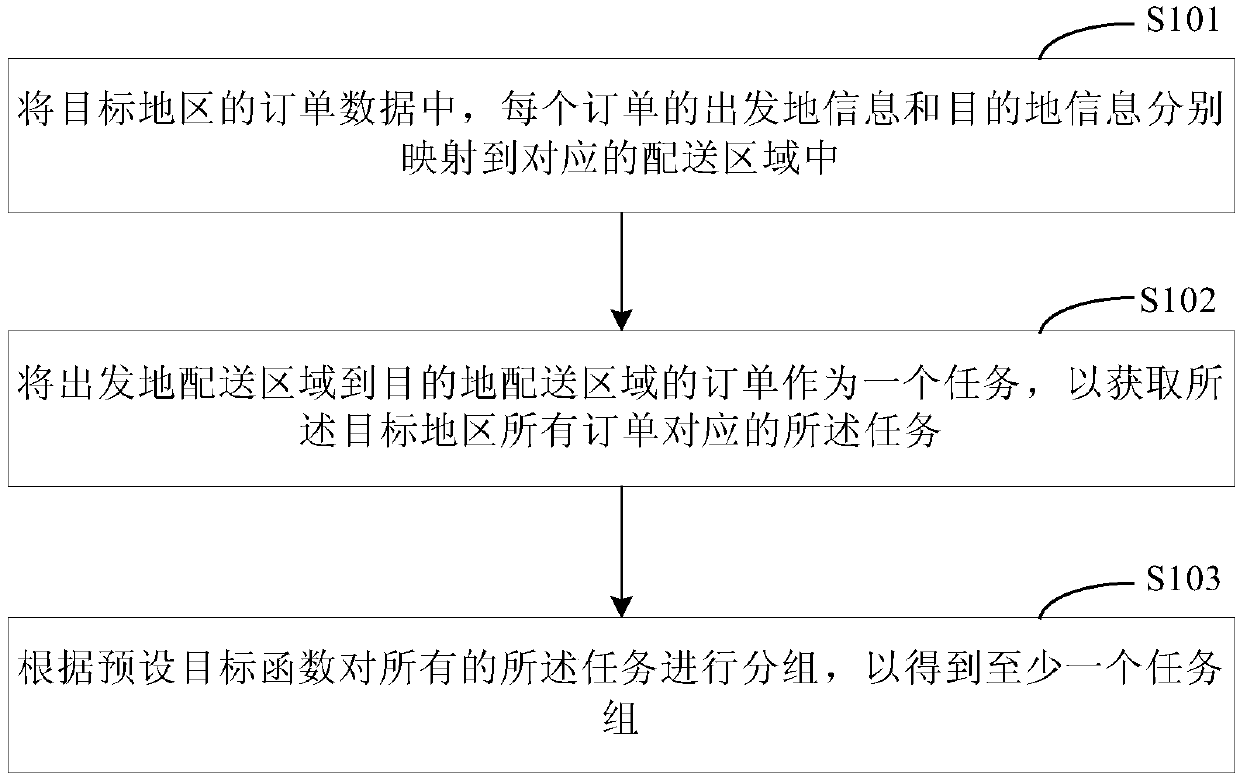

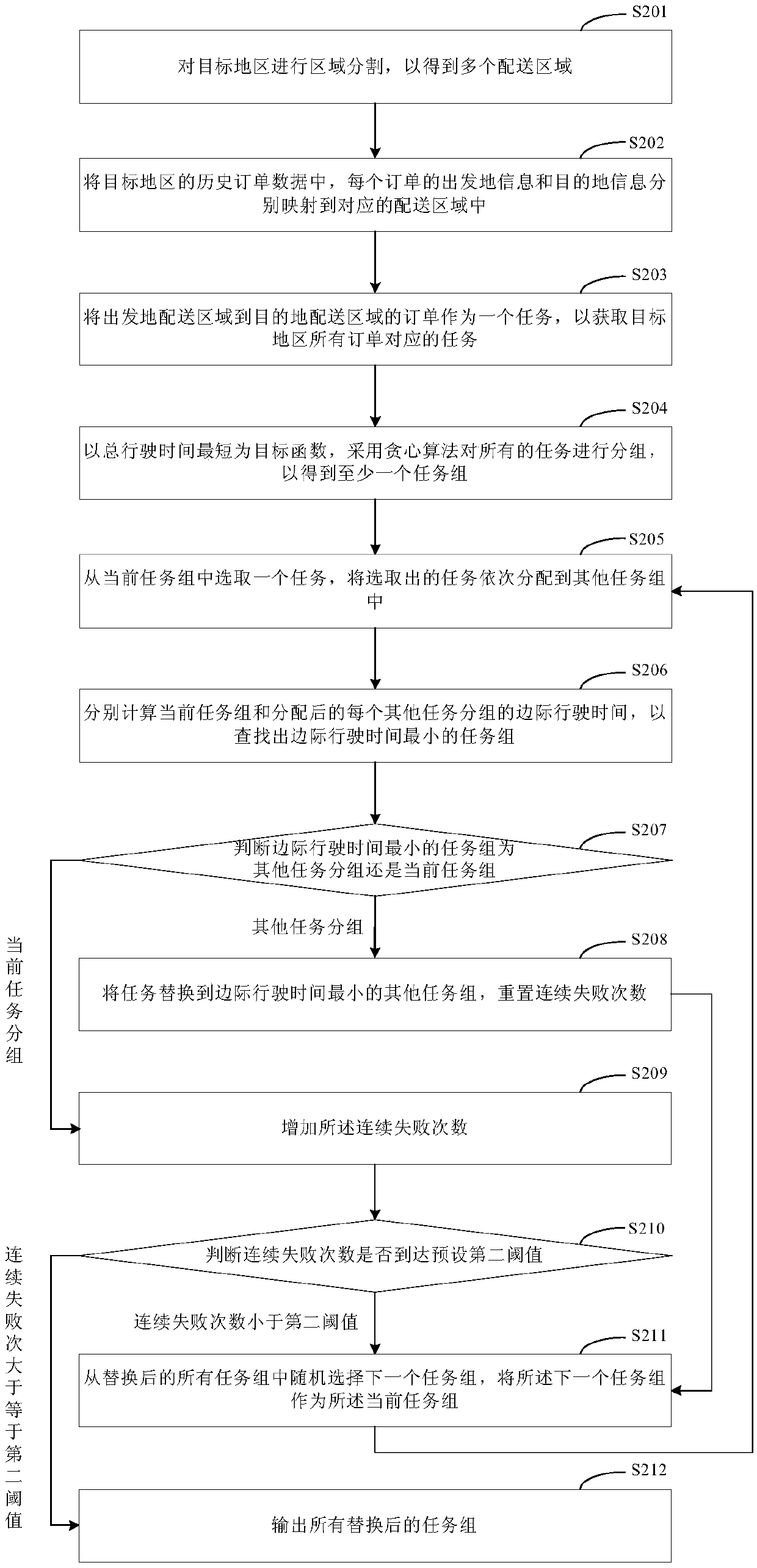

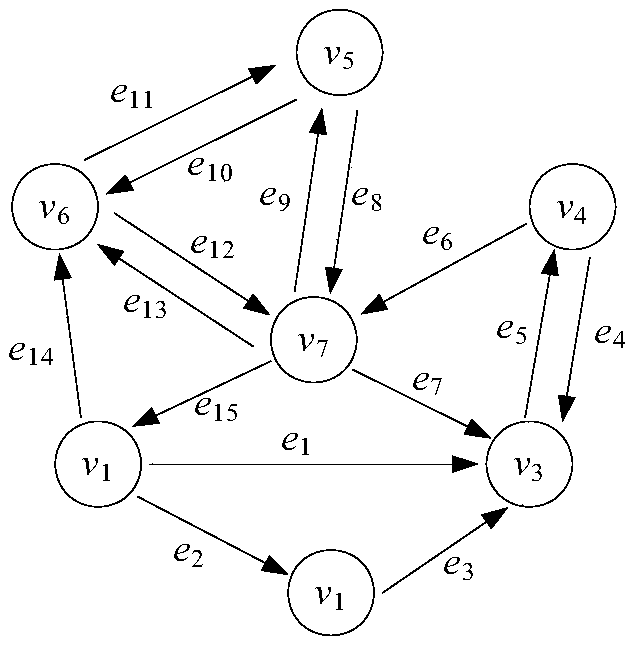

Order processing method and device

ActiveCN108734559AImprove experienceOptimize grouping resultsBuying/selling/leasing transactionsResourcesOrder formOrder processing

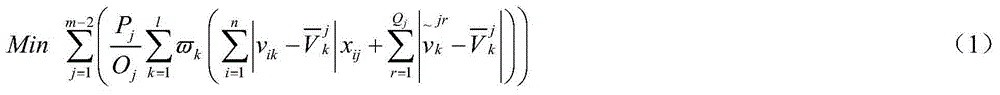

The invention discloses an order processing method and device, relating to the technical field of computers. One specific implementation manner of the method comprises the steps of separately mappingorigin information and destination information of each order among order data of a target area to corresponding distribution areas, wherein the distribution areas are obtained by dividing the target area; considering an order from the origin distribution area to the destination distribution area as a task, so as to acquire tasks corresponding to all orders of the target area; and grouping all tasks according to a preset target function, so as to obtain at least one task group. According to the method, the origin information and the destination information of the order are separately mapped tocorresponding distribution areas, then the order from the origin distribution area to the destination distribution area is considered as a task, and all obtained tasks are grouped based on the targetfunction, so that the distribution efficiency is improved, and the user experience is improved.

Owner:JINGDONG TECH HLDG CO LTD

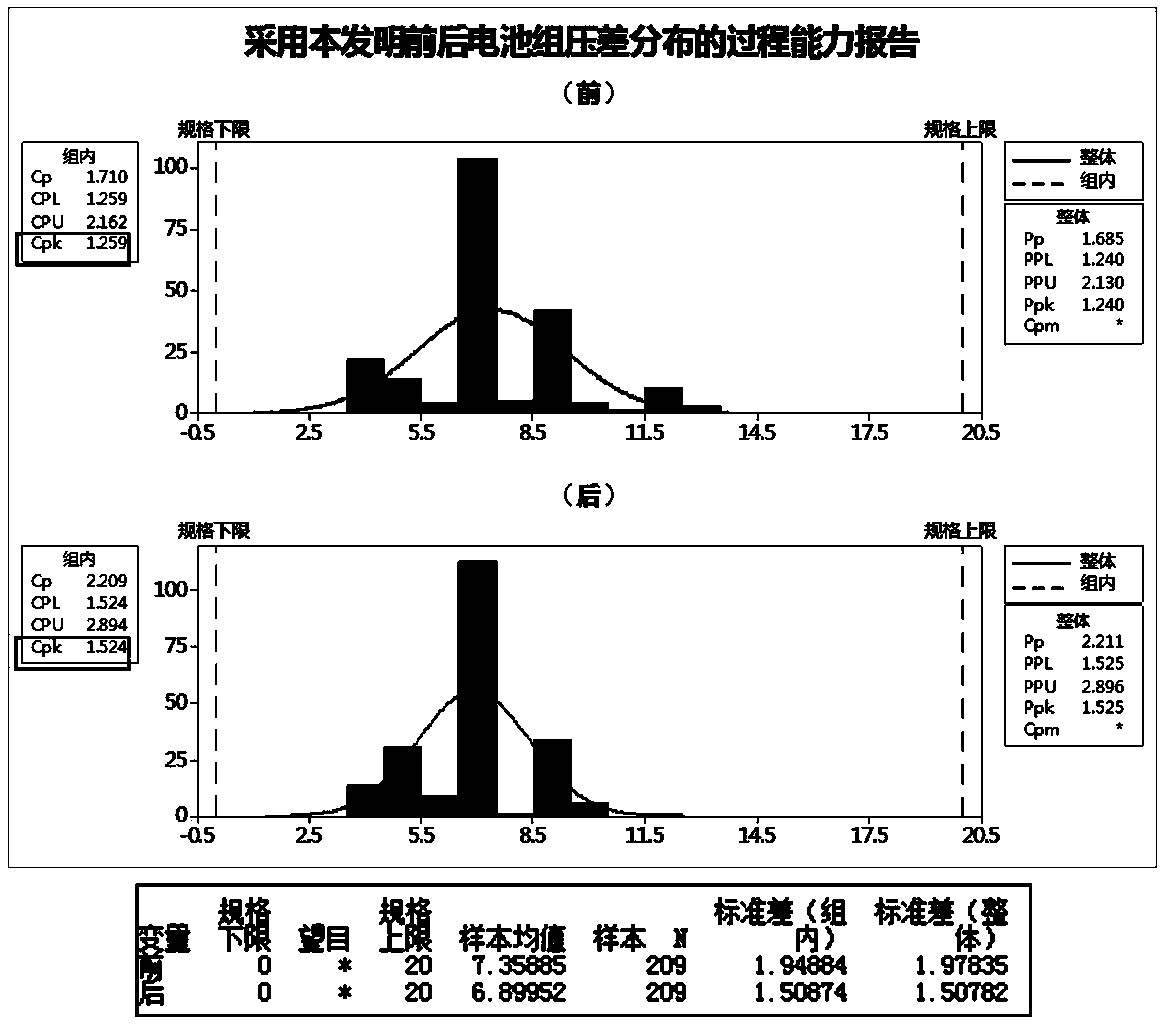

Self-discharge screening method for improving matching consistency of lithium ion batteries

InactiveCN109482521AFully self-dischargedAccurate measurementSortingElectrical batteryScreening method

The invention discloses a self-discharge screening method for improving the matching consistency of lithium ion batteries. The self-discharge screening method for improving the matching consistency ofthe lithium ion batteries comprises the following steps that after the same batch of batteries are subjected to conventional capacity grading, 5-20% SOC state-of-charge electric quantity is charged in a 4-6A current constant current charging mode. After the batteries are put on hold at normal temperature for 24-48h, the battery voltage is measured as OCV1, then the temperature is turned to 45 DEGC, and the batteries are put on hold for 120-168h, then the battery voltage is measured as OCV 2, then the batteries are put on hold at normal temperature, the battery voltage is measured as OCV3 again, values of OCV1, OCV2 and OCV3 are measured, and the voltage difference is calculated, that is , delta V1= OCV1-OCV2 and delta V2= OCV2-OCV3; and an out-of-tolerance value code of the delta V1 is VO1, an out-of-tolerance value code of the delta V2 is VO2, a batch of out-of-tolerance batteries can be roughly eliminated with a VO1 set value, and then a batch of the batteries can be finely eliminated with a VO2 set value. The self-discharge screening method for improving the matching consistency of the lithium ion batteries has simple and convenient implementation, high matching precision, good consistency and high matching efficiency, and is especially suitable for batch production application.

Owner:JIANGSU FRONT NEW ENERGY +1

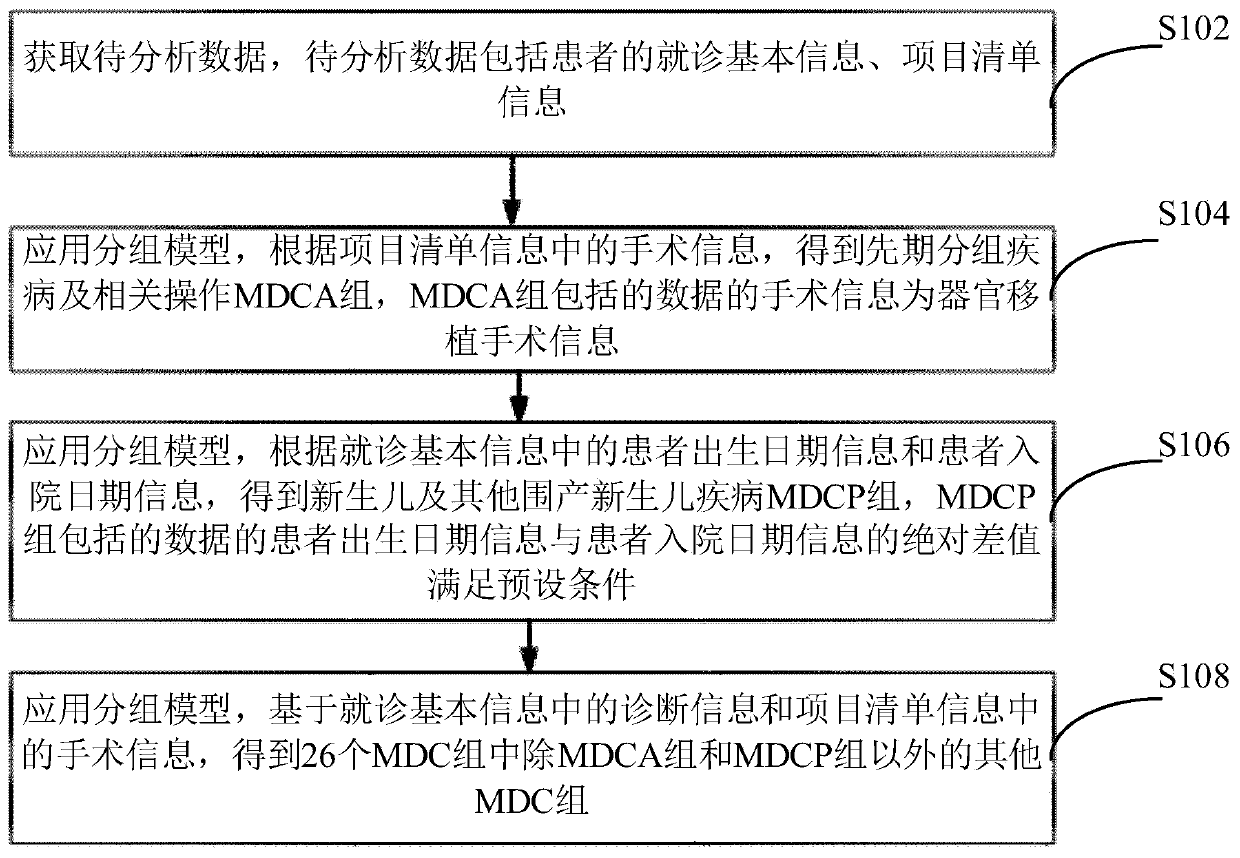

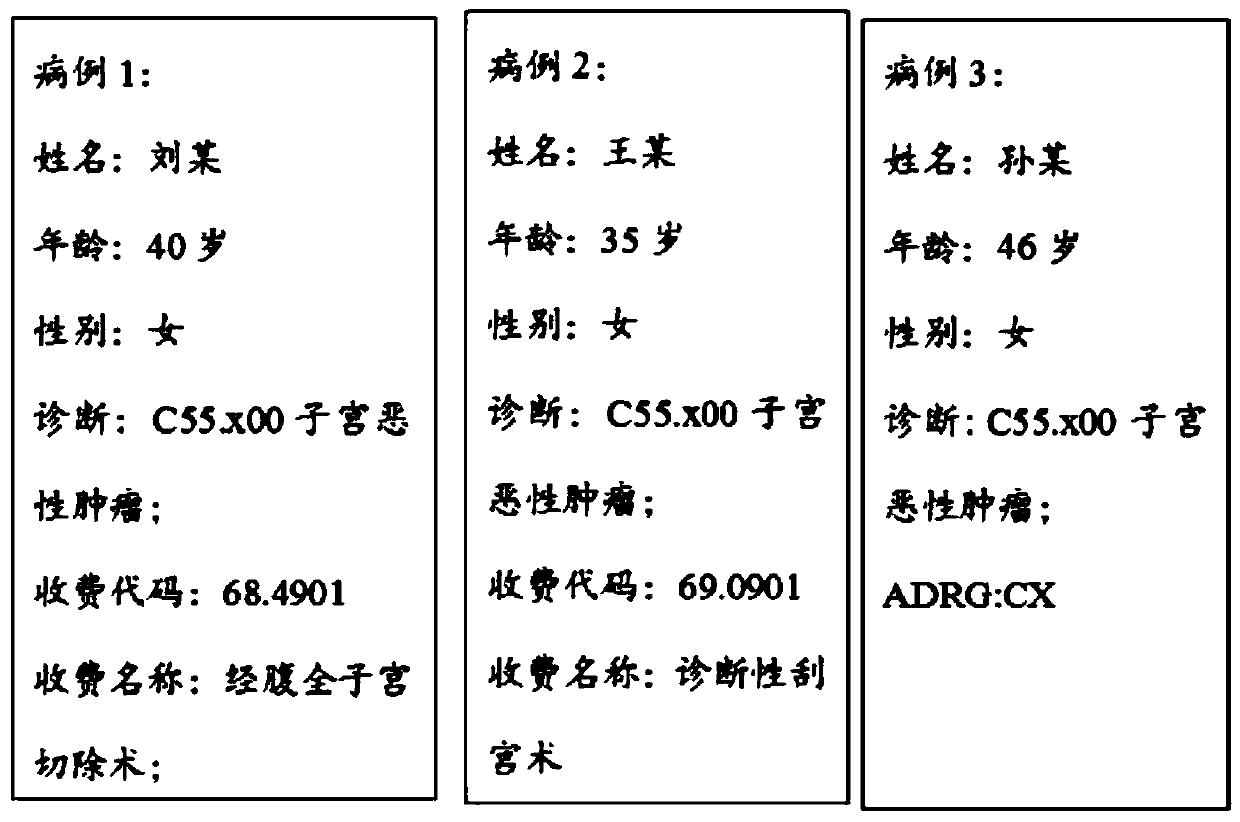

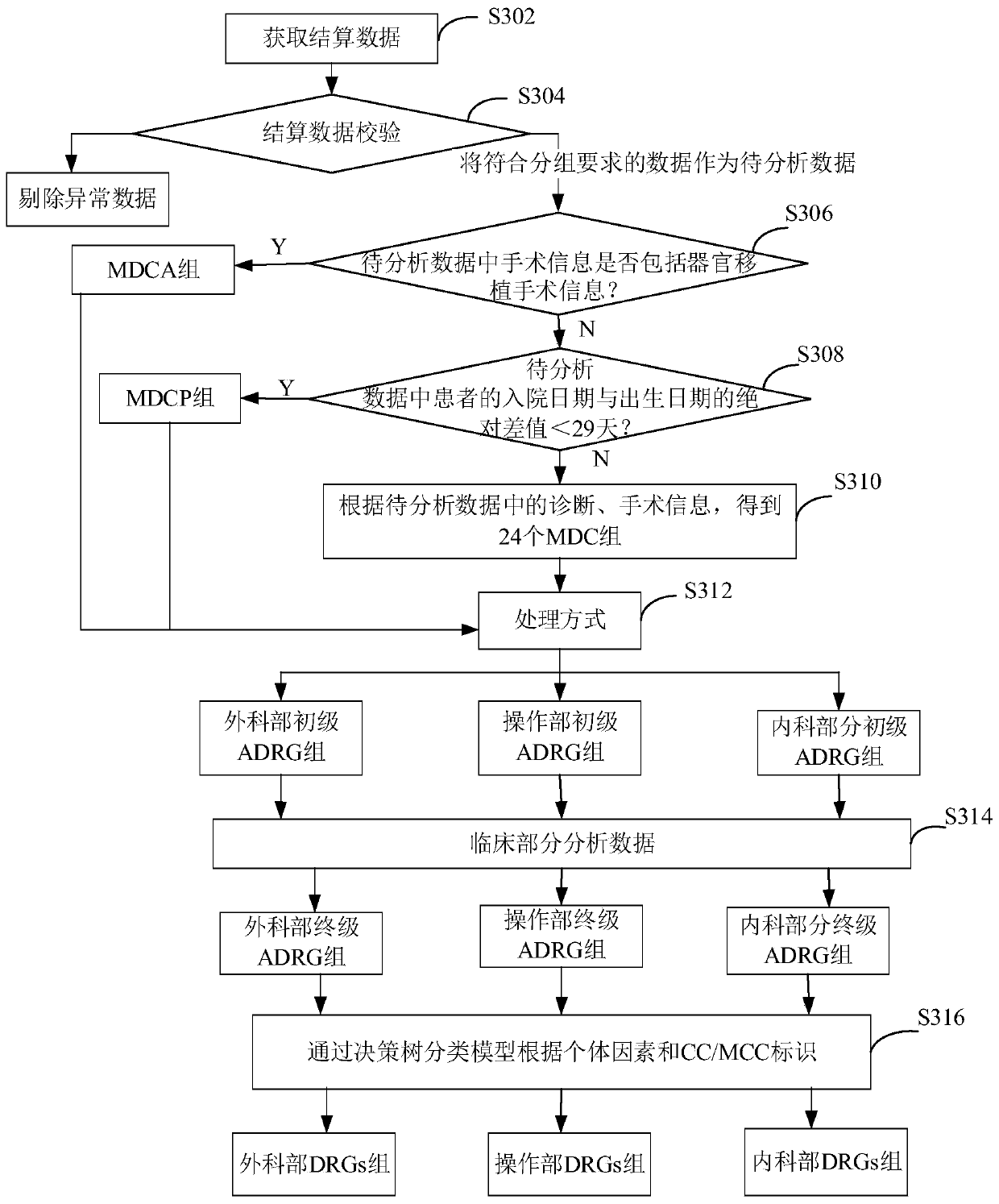

Method and device for DRGs grouping of medical insurance data, and electronic equipment

InactiveCN110706769ASteps to reduce repeated groupingEasy to operateFinancePatient-specific dataAnalysis dataDiagnostic information

The invention discloses a method and device for DRGs (Diagnosis Related Groups) grouping of medical insurance data, and electronic equipment. The method comprises the steps of: obtaining to-be-analyzed data which comprises treatment basic information and project list information of a patient; applying a grouping model to obtain an MDCA group according to the operation information in the project list information; applying the grouping model to obtain an MDCP group according to the patient birth date information and the patient admission date information in the treatment basic information; and obtaining other MDC (Major Diagnostic Category) groups except the MDCA group and the MDCP group in the 26 MDC groups by applying the grouping model based on the diagnosis information in the treatment basic information and the operation information in the project list information. According to the method, the to-be-analyzed data can be divided into the MDC groups by applying the grouping model, theto-be-analyzed data is grouped to obtain the MDCA group and the MDCP group, and then the remaining to-be-analyzed data is grouped to obtain other MDC groups, so that the whole operation process is simple, and the grouping efficiency is improved.

Owner:上海金仕达卫宁软件科技有限公司

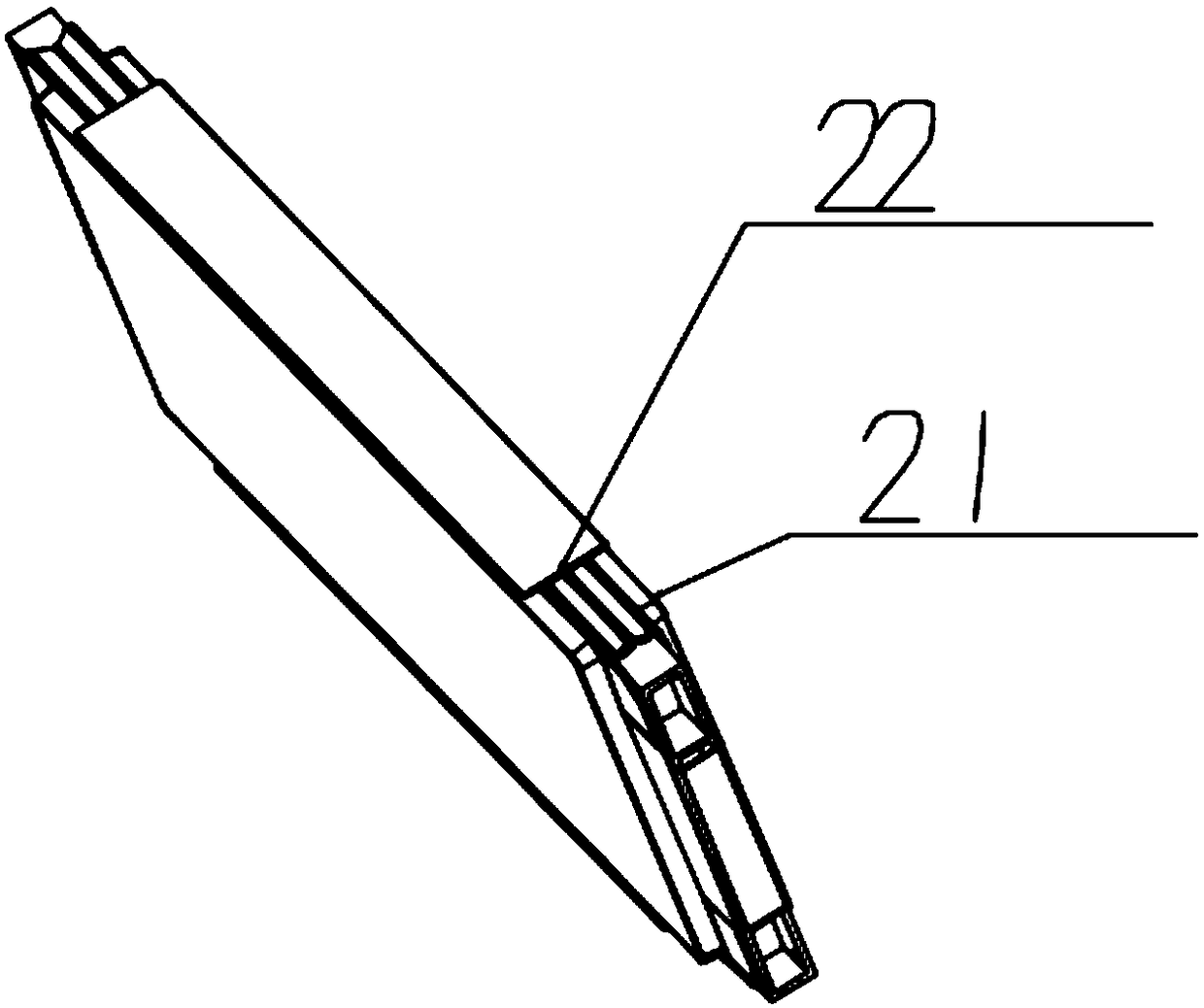

Busbar-free battery module, busbar-free battery module assembling method and battery pack

The invention provides a busbar-free battery module, a busbar-free battery module assembling method and a battery pack, and relates to the technical field of batteries. The busbar-free battery modulecomprises a plurality of battery cells, and each battery cell is provided with a connecting tab, each connecting tab comprises a first segment and a second segment, and the first segments are connected with the battery cells and are bent by a first preset angle relative to the battery cells; the second segments are connected to ends, far away from the battery cell, of the first segments and are bent by a second preset angle relative to the first segments. The second sections extend in the same direction, and the second sections are welded. According to the busbar-free battery module, a busbaris not needed, a plurality of connecting tabs are directly welded, the structure is simple, and the weight of the battery module is favorably reduced.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD

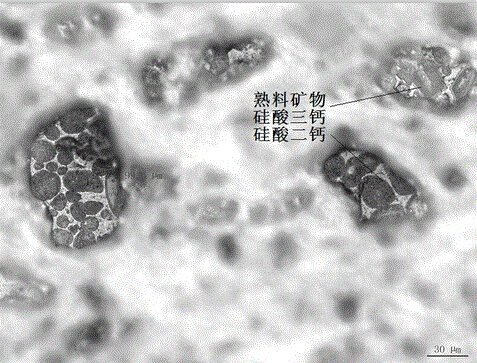

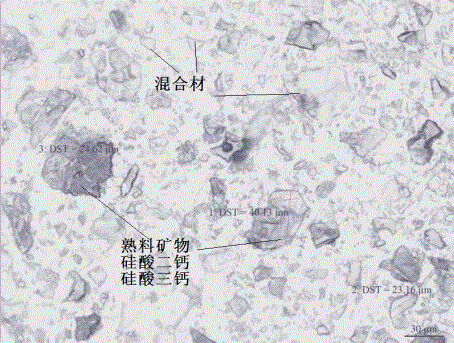

Method for analyzing lithofacies of powder samples

InactiveCN104865185ATimely monitoringTimely adjustmentPreparing sample for investigationMaterial analysis by optical meansAdhesiveMaterials science

The invention discloses a method for analyzing lithofacies of powder samples, which comprises six steps of mounting, coarse grinding, fine grinding, polishing, etching and petrographic analysis, wherein powder samples are added into adhesives to be made into a bulk shape, the adhesives are used to adhere powder cement together to be made into the bulk shape, and powder is powder clinker or cement. The method for analyzing lithofacies of powder samples is substantially used to analyze the lithofacies of the powder samples, solves the problem in the prior art that just bulk materials are analyzed, and has the advantages that the method for analyzing lithofacies of powder samples is simple in operation and has great guiding significance to productive process.

Owner:JIAHUA SPECIAL CEMENT

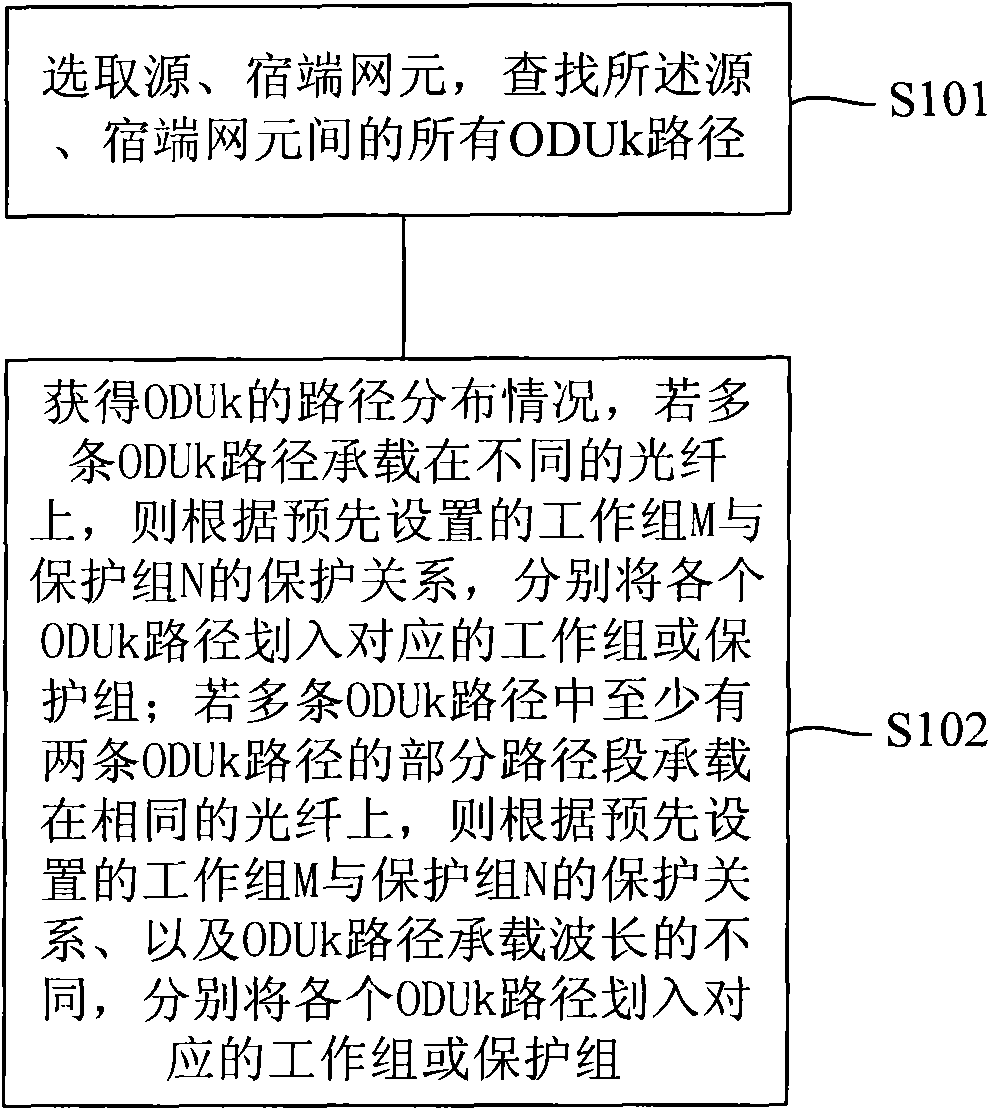

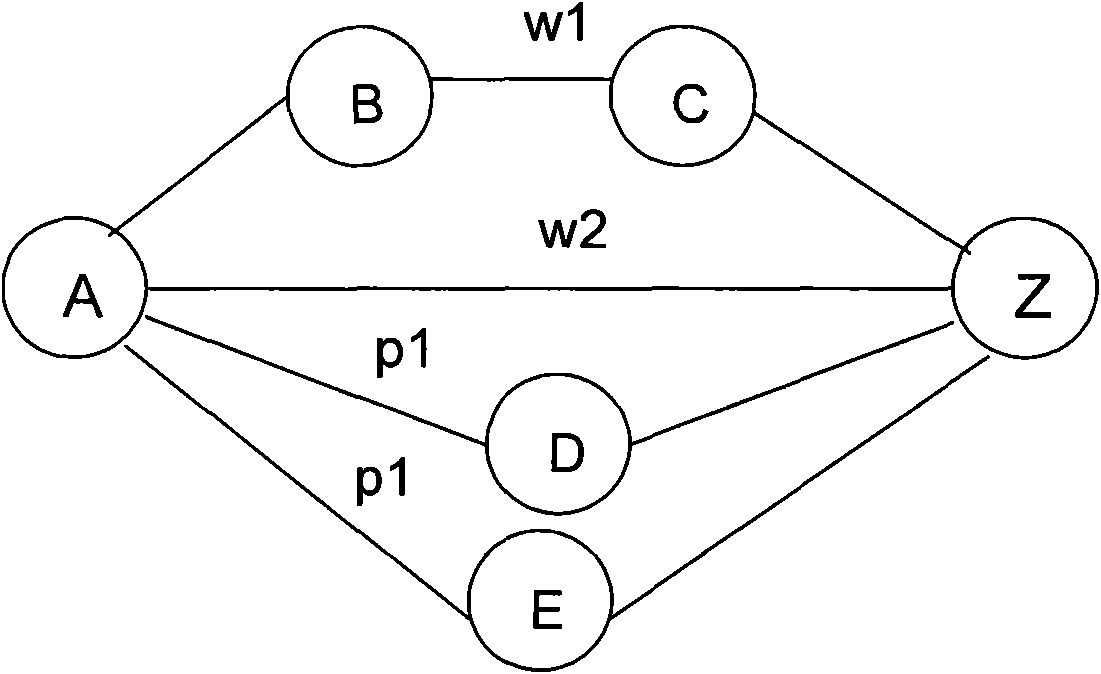

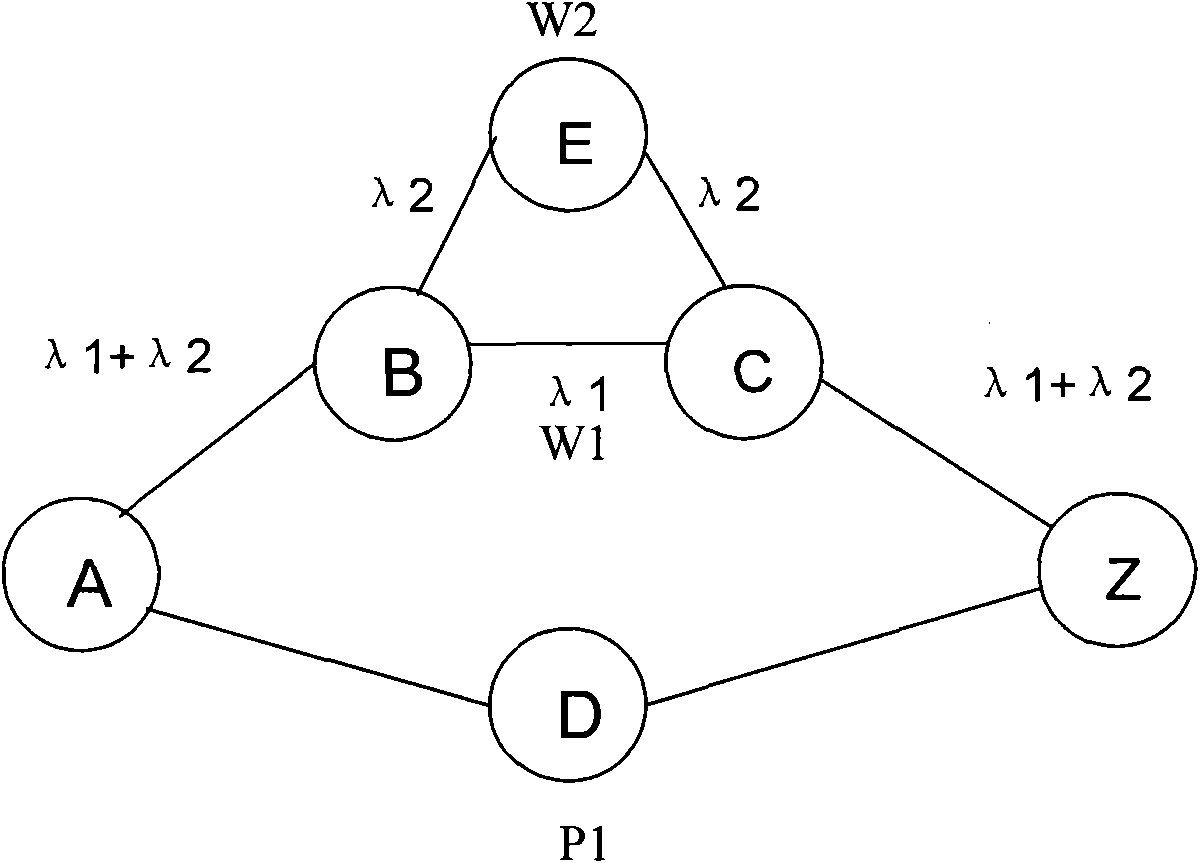

Path grouping method, device and system

InactiveCN102255739AReduce complex stepsImprove group efficiencyError preventionElectromagnetic transmissionChannel dataNetwork connection

The embodiment of the invention provides a path grouping method, a path grouping device and a path grouping system. The method comprises the following steps of: selecting a source network element and a destination network element and searching for all optical channel data unit-k (ODUk) paths between the source and destination network elements; obtaining the distribution conditions of the ODUk paths, and if the plurality of ODUk paths are born on different optical fibers, dividing each ODUk path into corresponding working groups or protection groups according to preset protection relationships between working groups M and protection groups N respectively; and if the path segments of at least two of the plurality of ODUk paths are partially born on the same optical fiber, dividing each ODUk path into the corresponding working groups or protection groups according to the preset protection relationships between the working groups M and the protection groups N and different ODUk path bearing wavelengths, wherein M and N are natural numbers. The embodiment of the invention improves grouping efficiency in M protection N optical channel data unit-k sub-network connection (MpN ODUk SNC) and simultaneously reduces error probability in the grouping.

Owner:HUAWEI TECH CO LTD

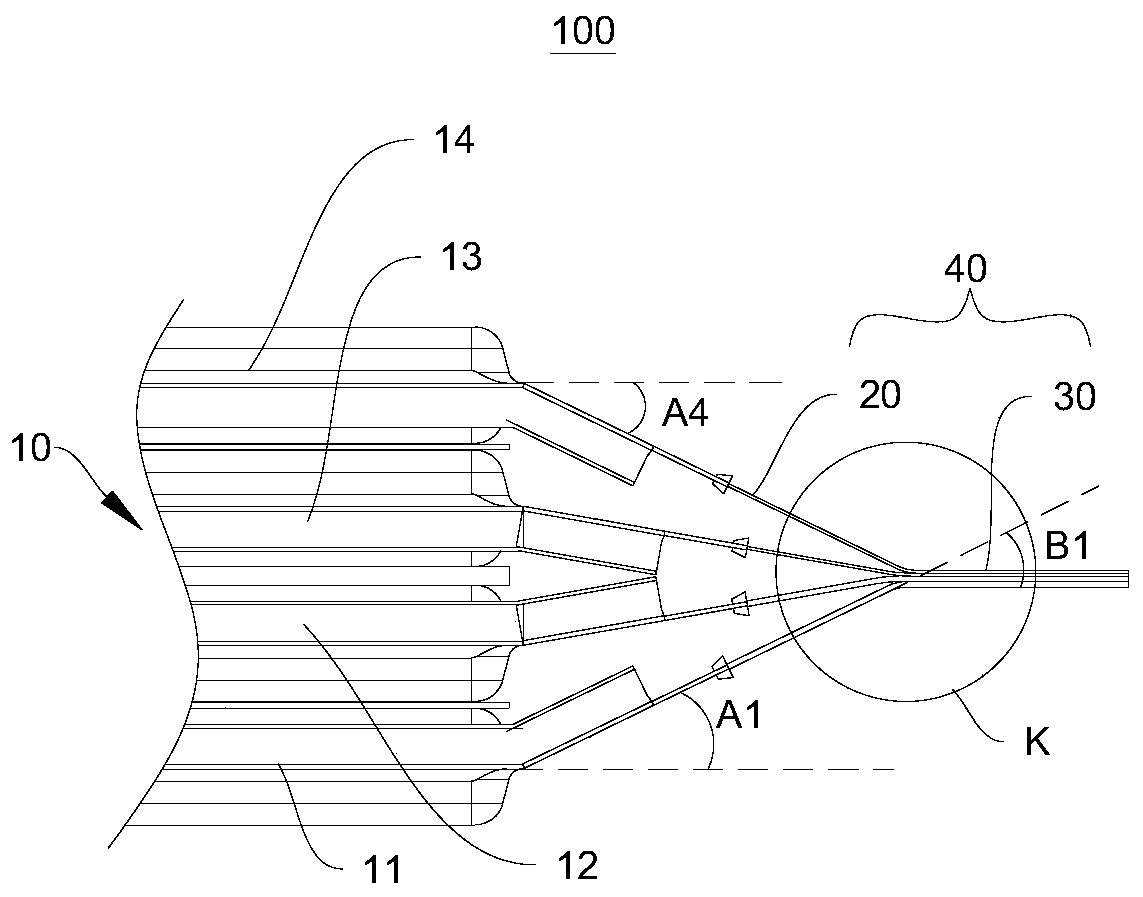

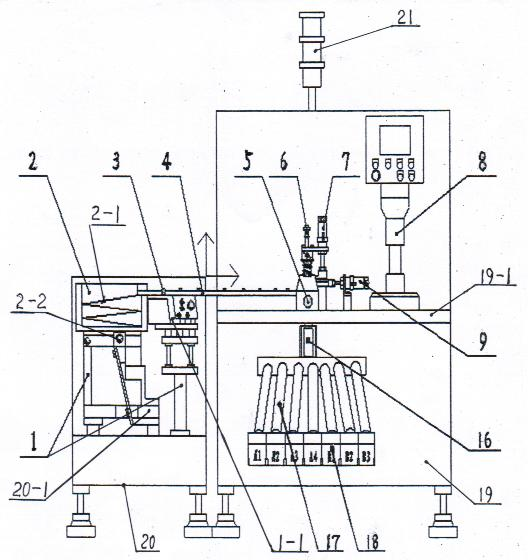

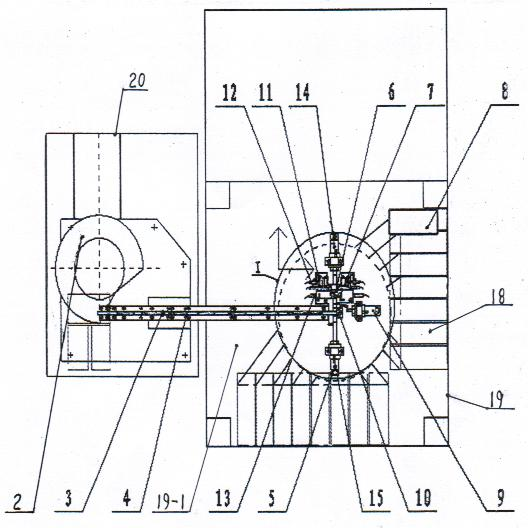

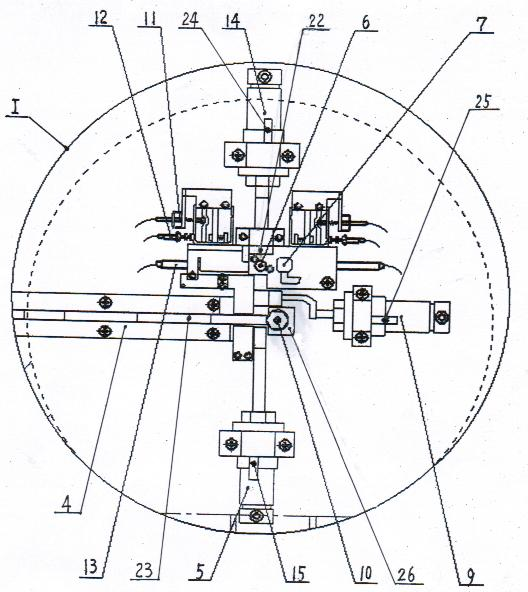

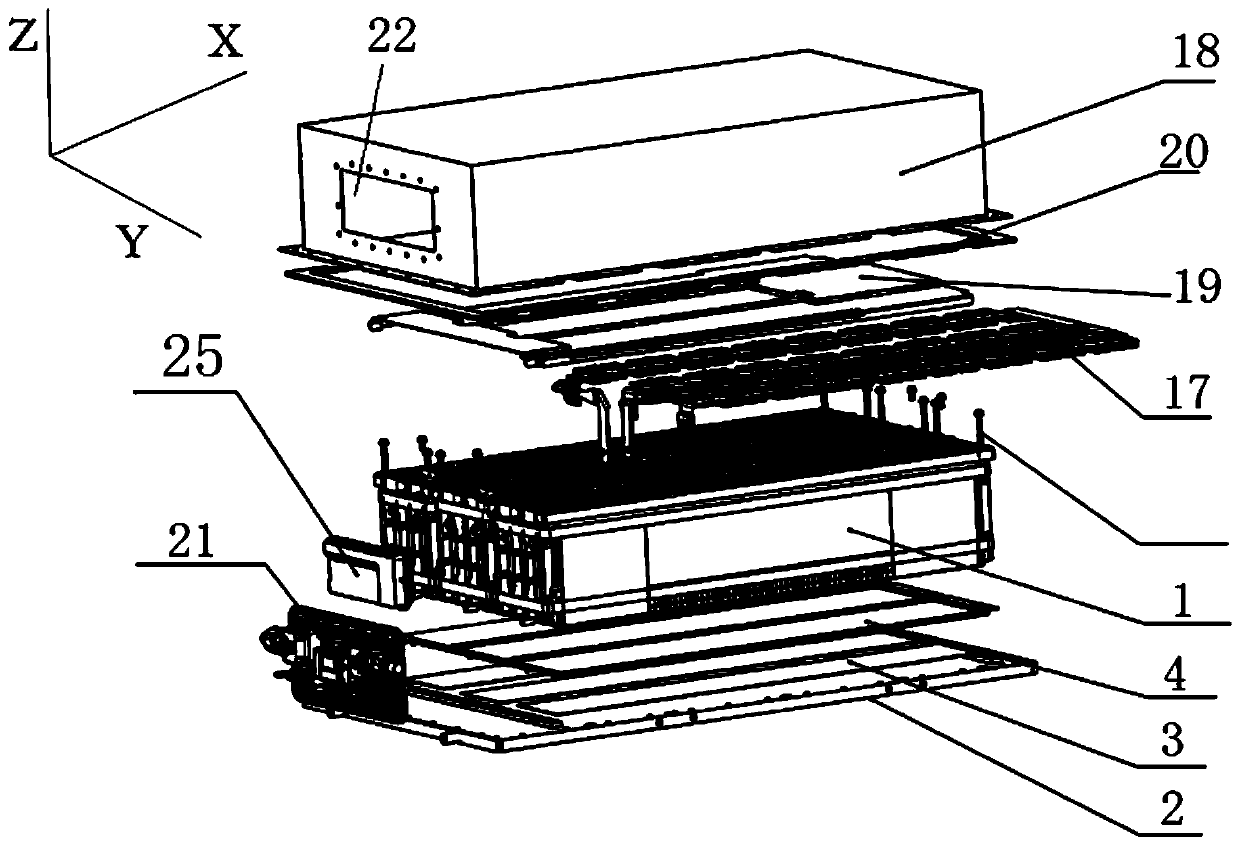

Automatic Blade Measuring Machine

The invention belongs to a measuring device for machining, particularly relates to an automatic blade measuring machine, comprising a vibrating feeding case (20), a measuring case (19), a carriage (1), charging barrel No.1 (16), charging barrel No.2 (17) and a magazine (18), wherein, the vibrating feeding case (20) is provided with a base plate (20-1) and the carriage (1), a delivery flat rack (1-1) and a spiral vibrating plate (2) are arranged on the carriage (1), a feeding controller (2-2) is arranged under the spiral vibrating plate (2), the spiral vibrating plate (2) is provided with a built-in feeding track (2-1), the upward side of the spiral vibrating plate (2) is connected with the left end of a delivery plate (4), one side surface of the delivery plate (4) is provided with an inductor No.1 (3), and the right end of the delivery plate (4) is connected with an inductor base (26) in the measuring case (19). The automatic blade measuring machine improves the efficiency of blade grouping, saves labor and time, and improves the labor productivity.

Owner:FUXIN DARE AUTOMOTIVE PARTS

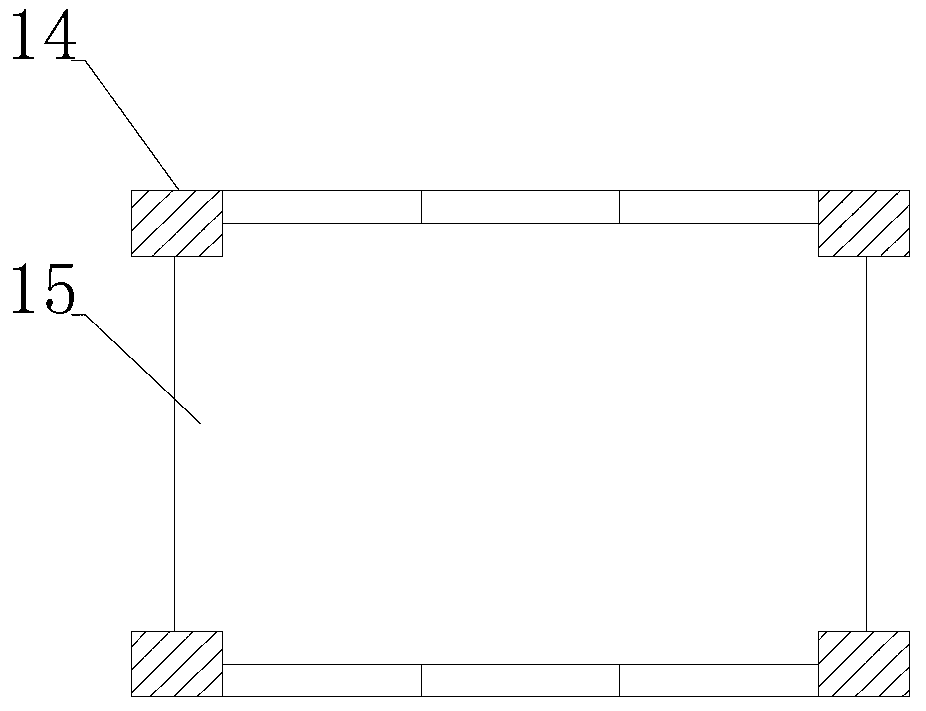

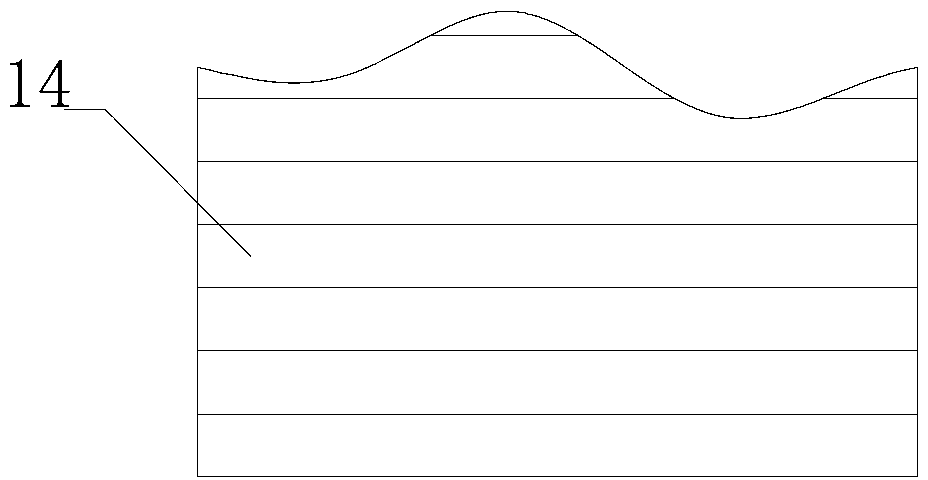

Battery module thermal runaway expansion suppression device based on heat tube

PendingCN107732368AImprove group efficiencyInhibit thermal runaway expansionSecondary cells servicing/maintenanceVehicular energy storageAutomotive batteryHeat conducting

The invention provides a battery module thermal runaway expansion suppression device based on a heat tube, and belongs to the technical field of the electromobile power battery management. The batterymodule thermal runaway expansion suppression device based on the heat tube comprises a battery module, a runner, a base and aluminium plate jackets. The battery module comprises multiple same batteryand heat tube module units. Each battery and heat tube module unit comprises two single batteries, two thermal insulating jackets, two heat-conducting aluminum plates, a heat tube group and a thermalinsulating bar. Two single batteries are fixed at the inner side of the thermal insulating jackets. Two heat-conducting aluminum plates are positioned between two single batteries. Two heat-conducting aluminum plates are fixed with the evaporation section of each heat tube in the heat tube group through the thermal insulating bar. The condensation section of the lower part of the heat tube is positioned in the runner and used for performing the heat convection. The battery module is integrally fixed with the front and rear aluminium plate jackets through the base. The device is capable of effectively controlling the temperature of the battery module and the surface temperature difference of the battery, suppressing the thermal runaway expansion in the battery module, improving the safetyof a electromobile battery system, and providing the guidance for the safety design of the battery module.

Owner:TSINGHUA UNIV

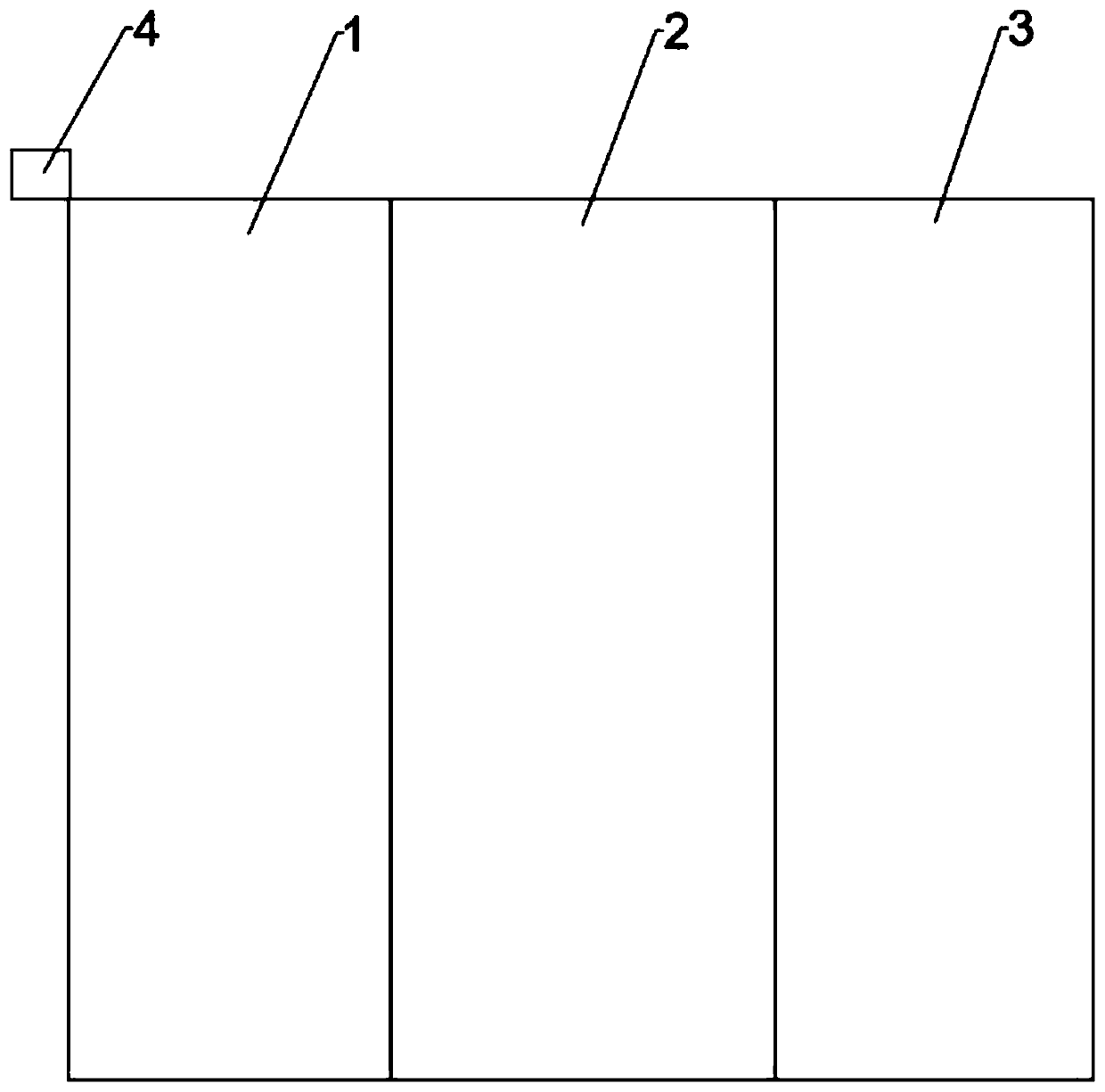

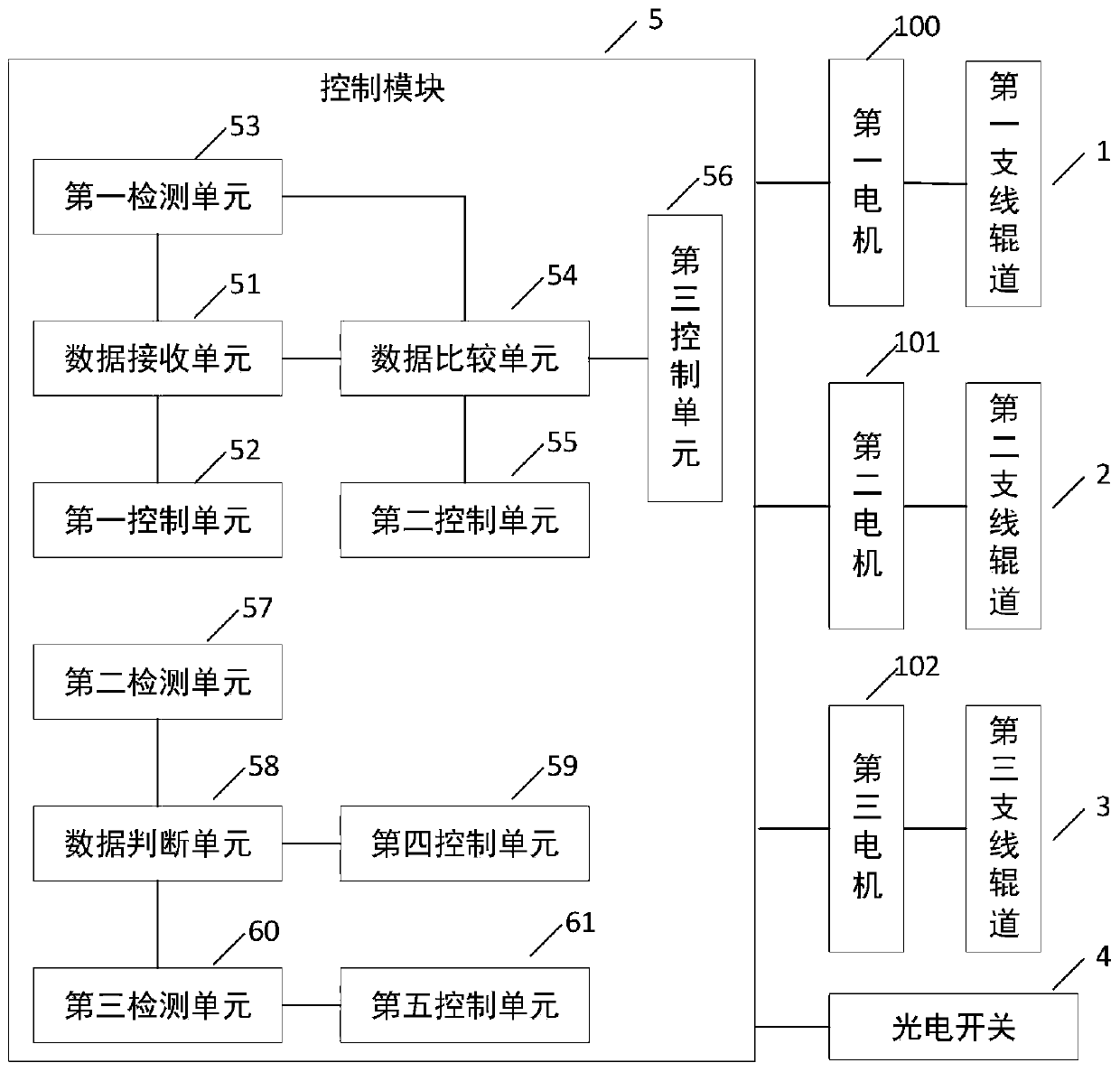

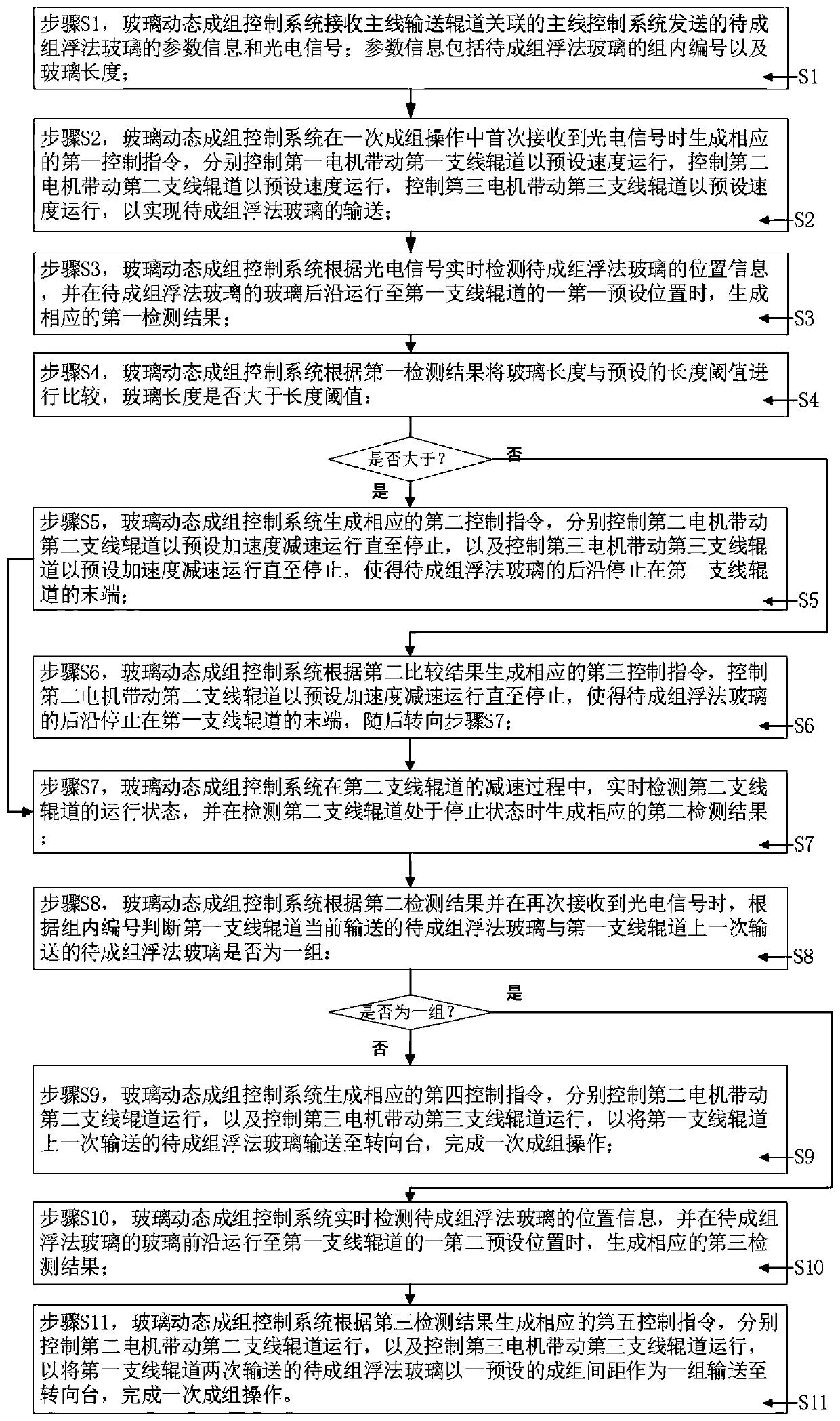

Glass dynamic grouping control system and method for float glass production line

ActiveCN110937793AControl start and stopImplement dynamic groupingGlass transportation apparatusPhotoswitchControl system

The invention provides a glass dynamic grouping control system and method for a float glass production line, and relates to the technical field of glass production. The glass dynamic grouping controlsystem comprises a first branch roller way, a second branch roller way, a third branch roller way, a photoelectric switch used for generating a photoelectric signal when detecting the float glass to be grouped, and a control module for controlling the first branch roller way, the second branch roller way and the third branch roller way to operate when receiving the photoelectric signal for the first time, wherein when the rear edge of the glass moves to a first preset position, if the length of the glass is greater than a length threshold, the second branch roller way and the third branch roller way are controlled to decelerate, and if not, the second branch roller way is controlled to decelerate, when the photoelectric signals are received again and the to-be-grouped float glass conveyedtwice is not in one group, the second branch roller way and the third branch roller way are controlled to operate, and when the photoelectric signals are received again and the to-be-grouped float glass conveyed twice is in one group and the front edge of the glass operates to a second preset position, the second branch roller way and the third branch roller way are controlled to operate. The glass dynamic grouping control system can be used for grouping glass of any specification and can control the grouping distance.

Owner:CHINA TRIUMPH INT ENG

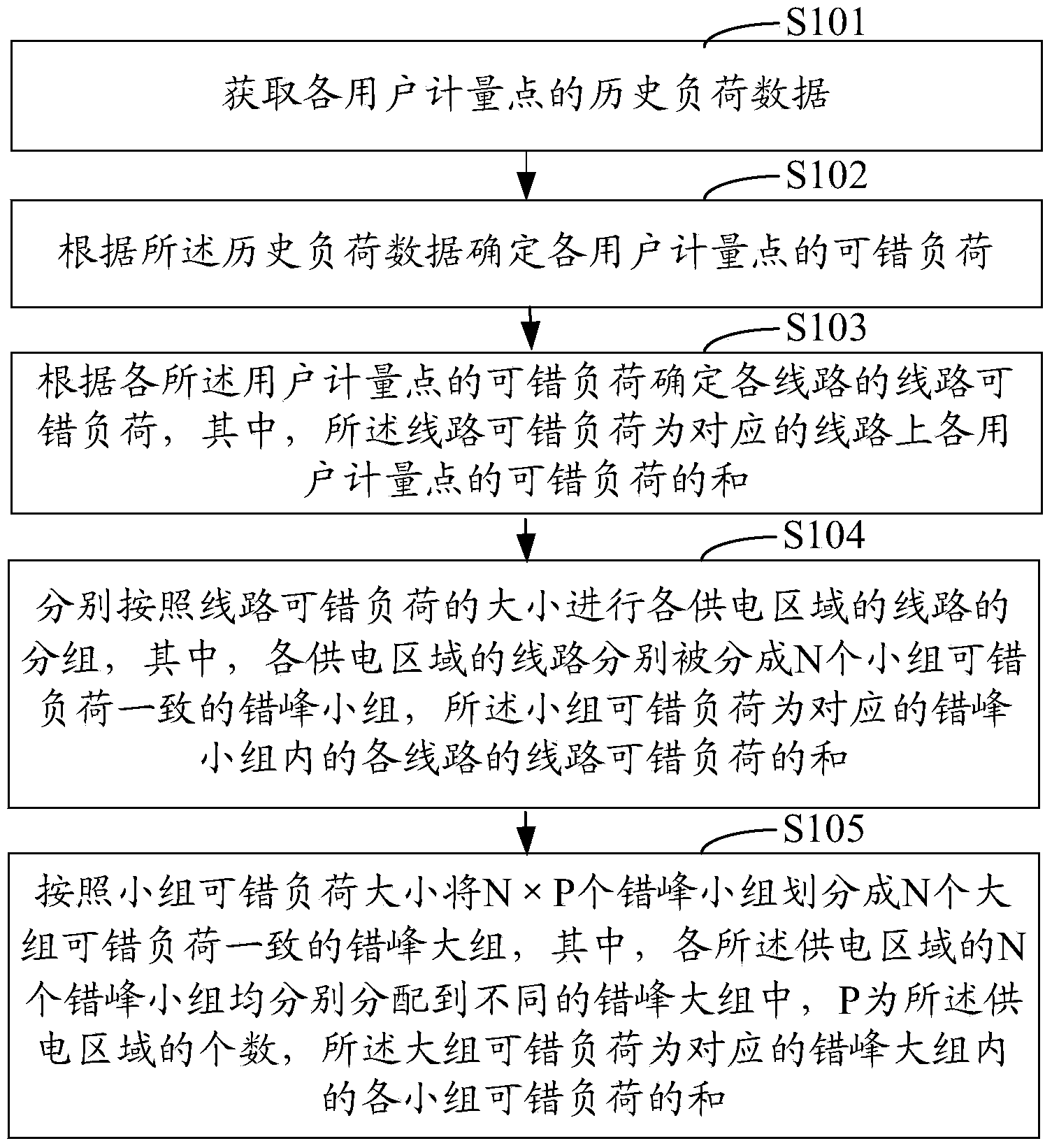

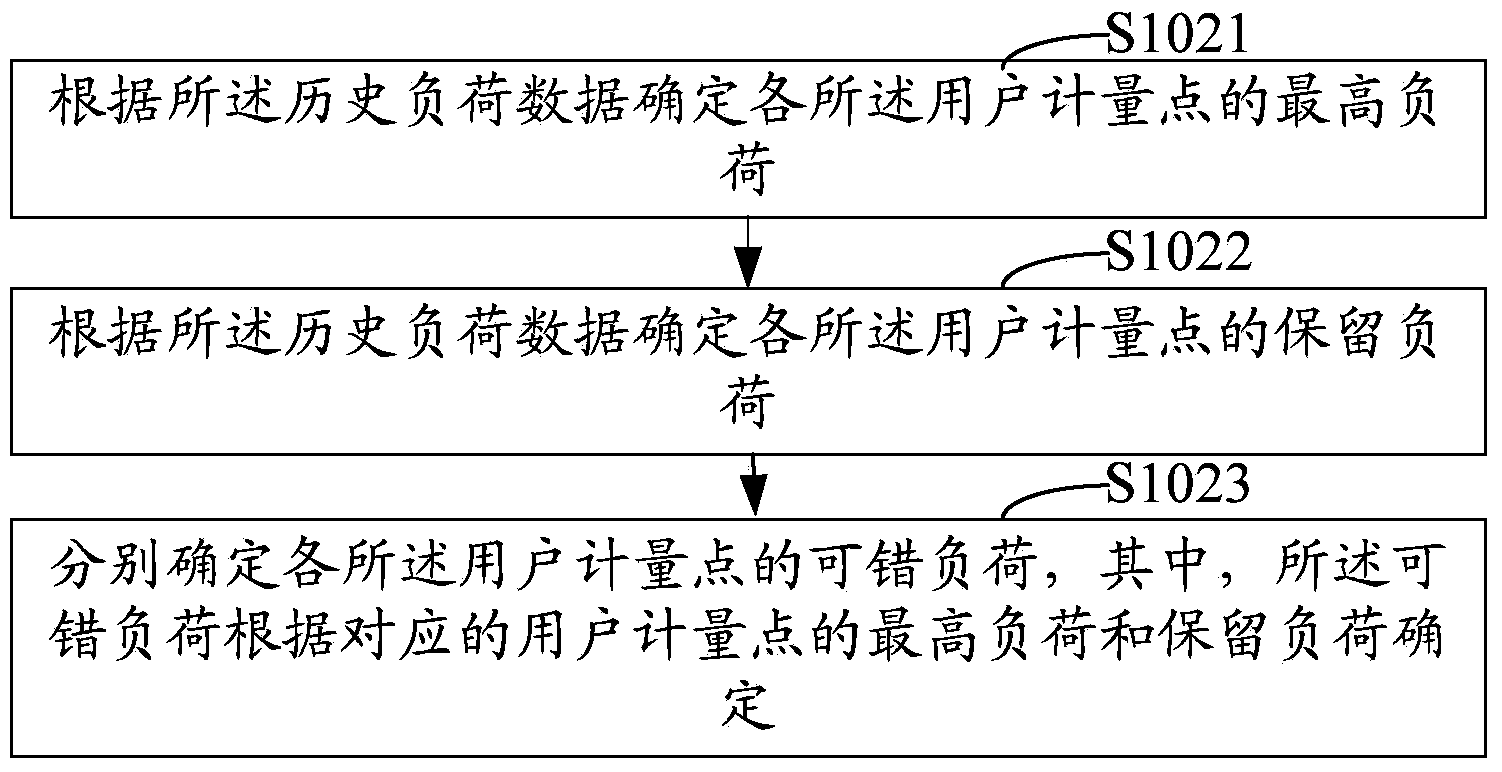

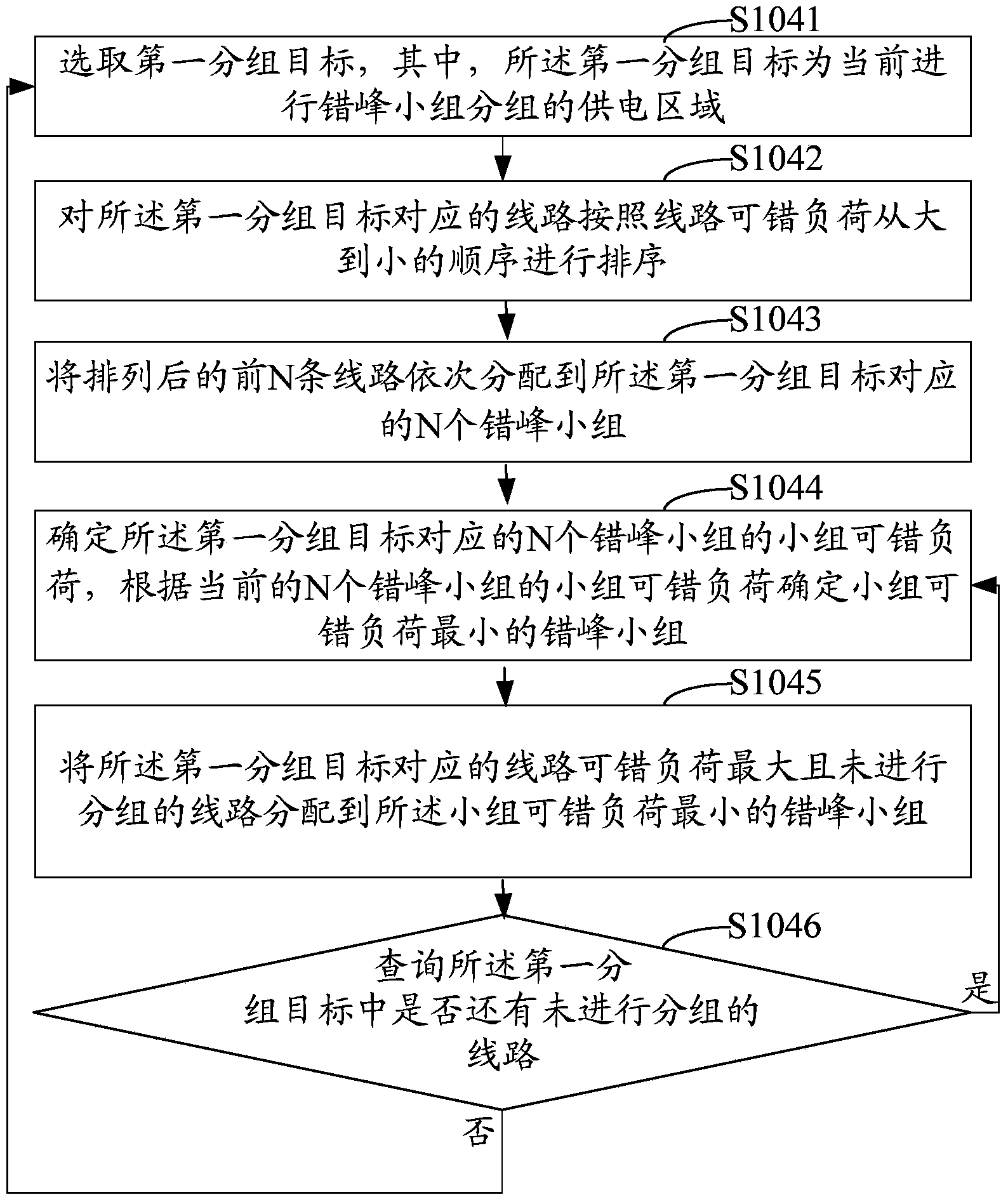

Grouping method and system of orderly-power-utility peak-staggering stagger-stop users

ActiveCN103455949AGet real-time and fastImprove accuracyData processing applicationsPower utilitySmall peak

The invention provides a grouping method and system of orderly-power-utility peak-staggering stagger-stop users. The grouping method of the orderly-power-utility peak-staggering stagger-stop users comprises the steps of (1) obtaining historical load data of user metering points; (2) determining stagger-possible loads of the user metering points according to the historical load data; (3) determining circuit stagger-possible loads of circuits according to the stagger-possible loads of the user metering points; (4) carrying out grouping on the circuits of each power supply area according to the circuit stagger-possible loads, wherein the circuits of each power supply area are divided into N small peak-staggering groups, and small-group stagger-possible loads of the N small peak-staggering groups are consistent; (5) dividing N*P small peak-staggering groups into N large peak-staggering groups according to the small-group stagger-possible loads, wherein large-group stagger-possible loads of the N large peak-shifting groups are consistent, the N small peak-staggering groups of each power supply area are distributed into different large peak-staggering groups, the P is the number of the power supply areas, and the large-group stagger-possible load is equal to the sum of the small-group stagger-possible loads of the small peak-staggering groups in each corresponding large peak-staggering group. According to the grouping method and system of the orderly-power-utility peak-staggering stagger-stop users, accuracy and efficiency of grouping can be improved.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

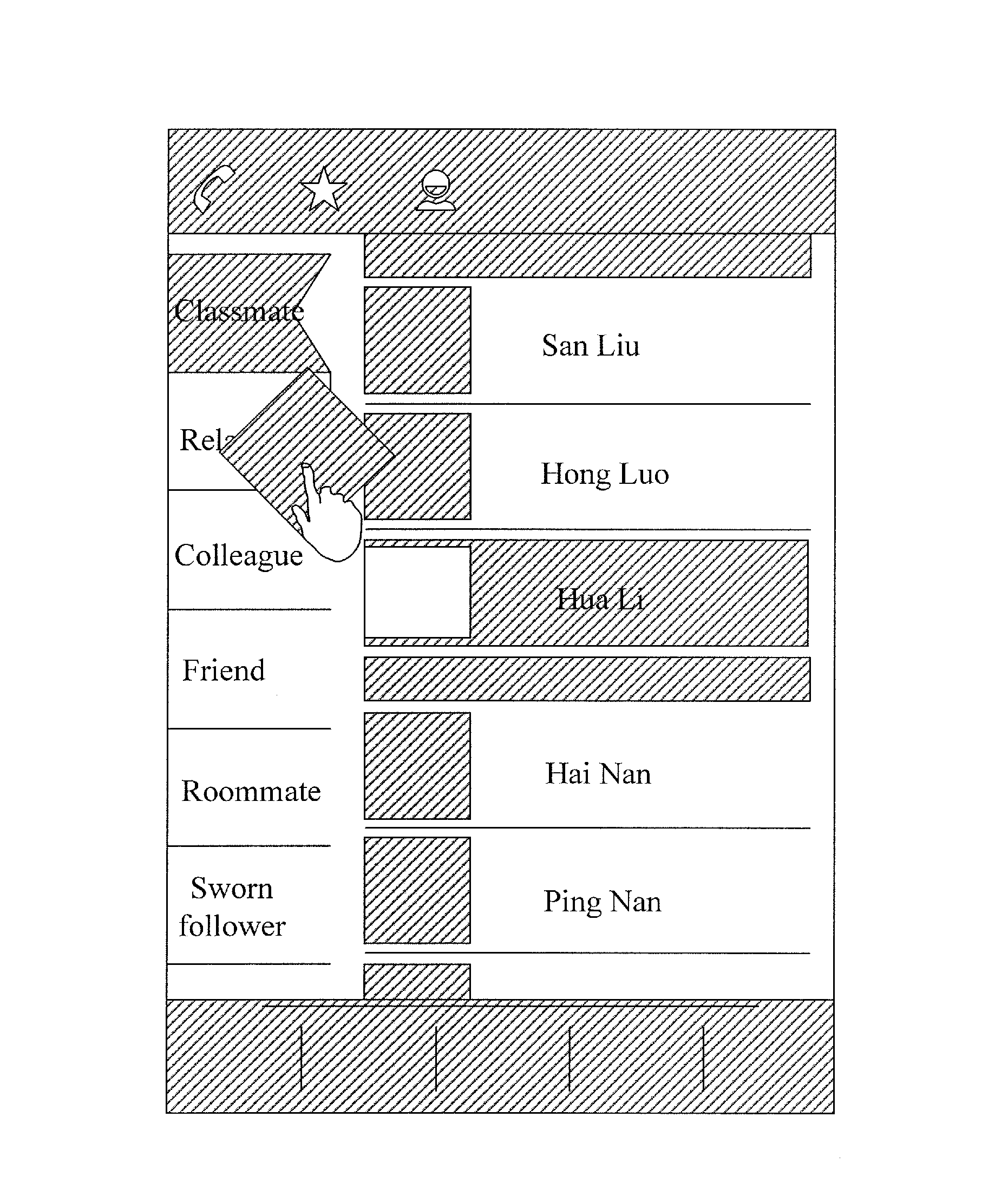

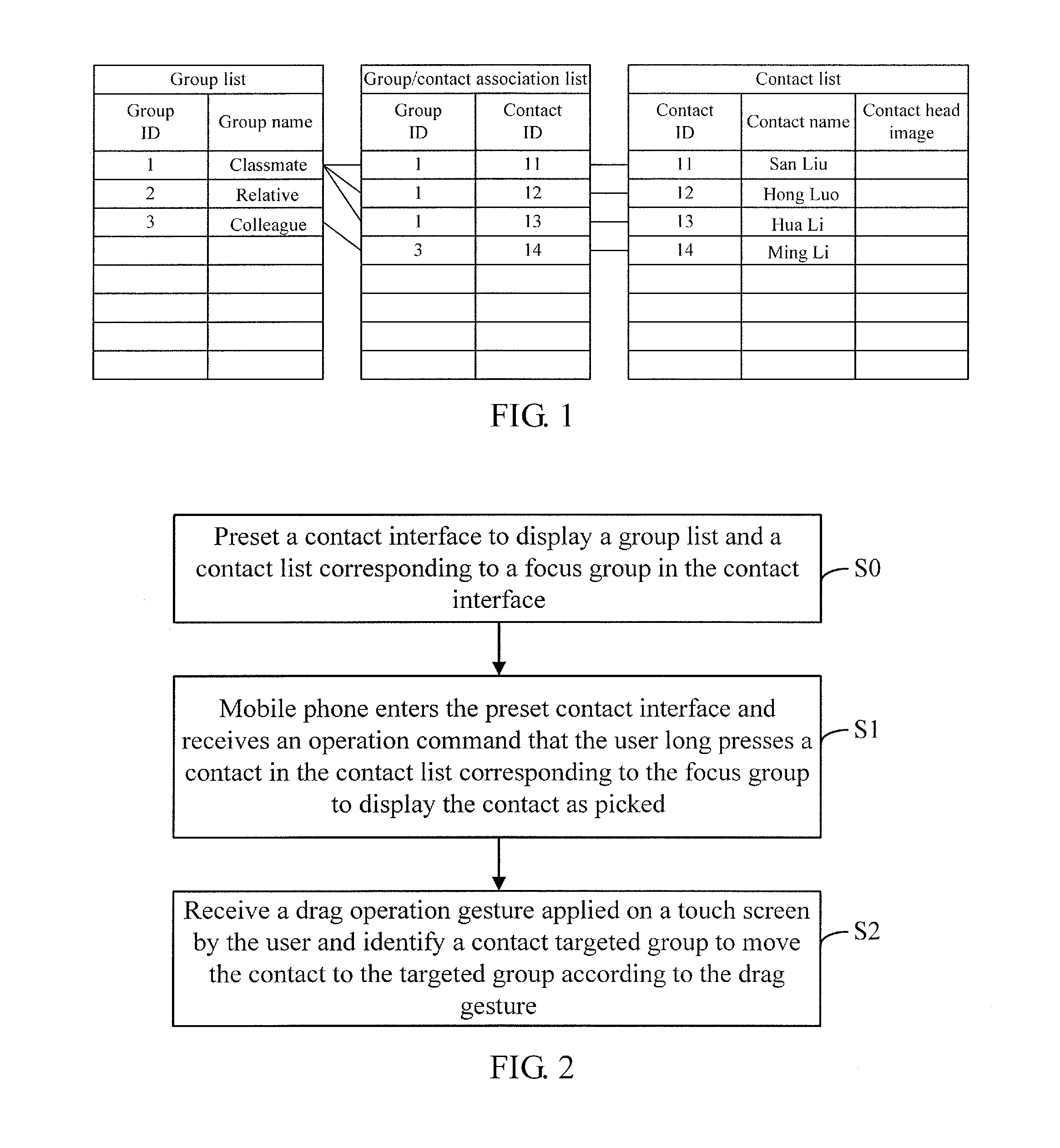

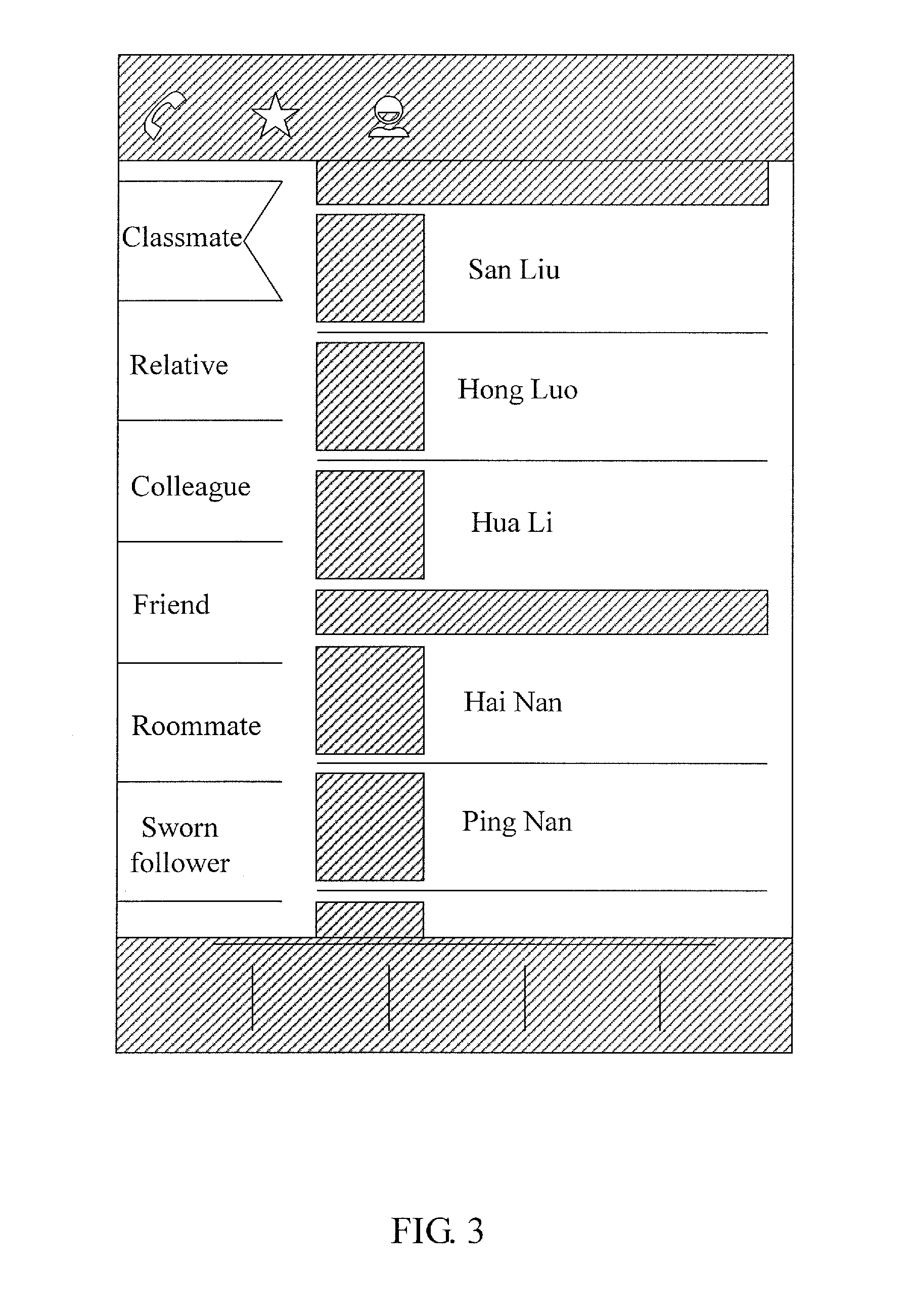

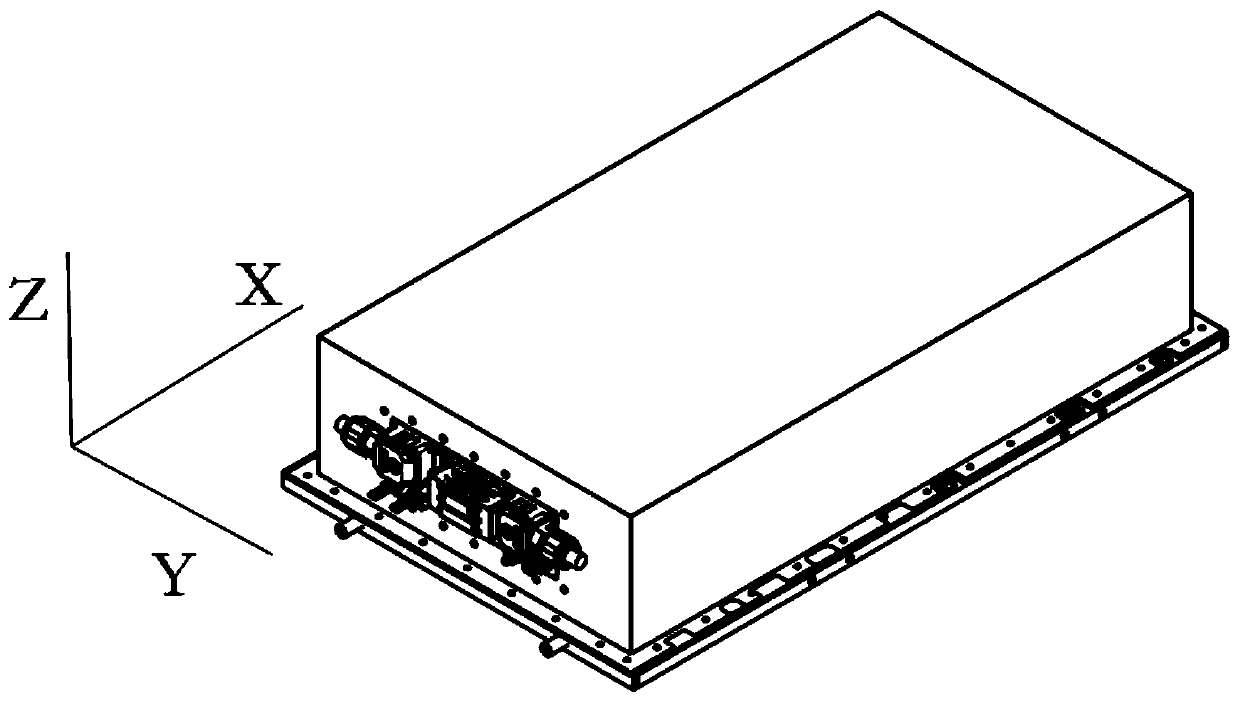

Method and device for processing contact information groups

InactiveUS20150074539A1Easy to operateEasy to handleRelational databasesSubstation equipmentSimulationContact list

A method and a device for processing contact information group are proposed. The method includes: entering a contact interface according to a first operation command from an user; displaying a contact in a contact list corresponding to a focus group as picked according to a second operation command from the user; and identifying a targeted group of the contact and moving the contact to the targeted group according to a third operation command from the user. By using the present invention, the user can rapidly groups all the contacts through a single operation interface.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

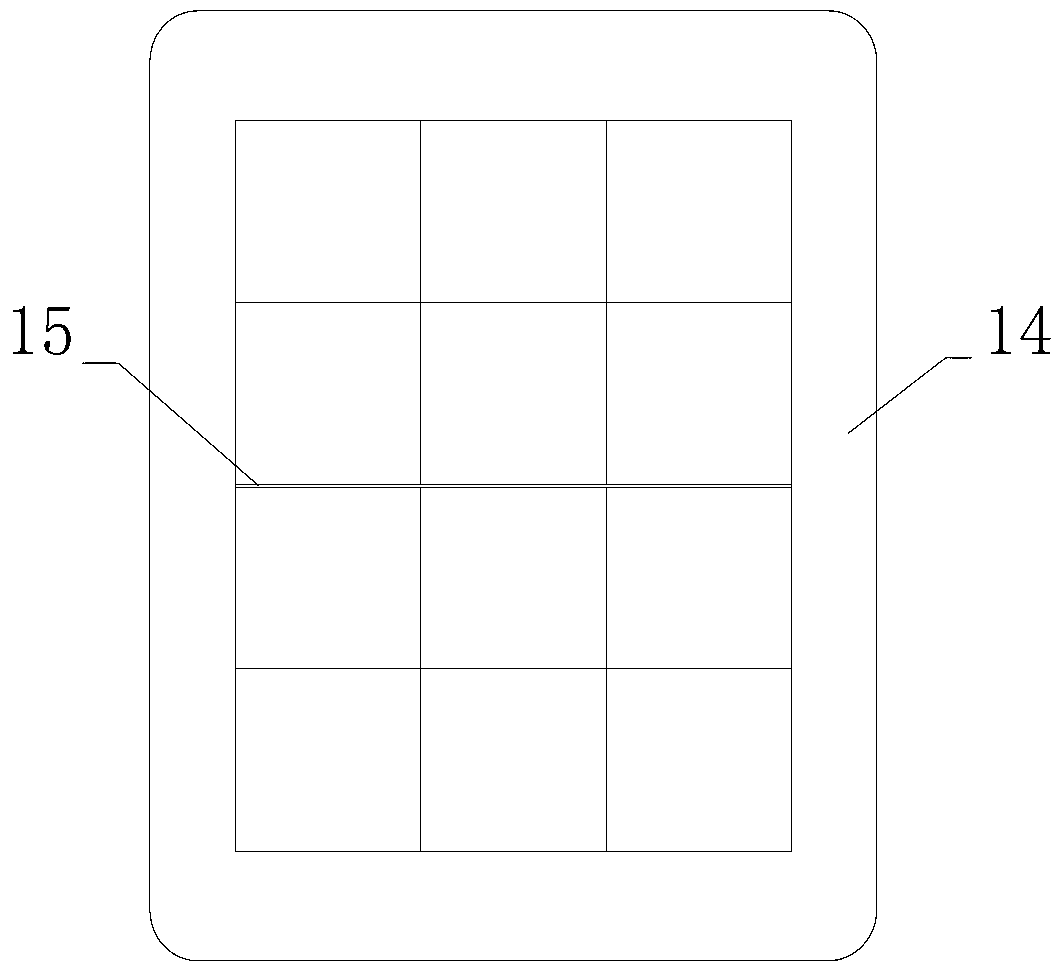

Power battery pack structure and assembly process thereof

InactiveCN110364655AModularizationReduce post-maintenance costsSecondary cellsCell component detailsPower batteryEngineering

The invention discloses a power battery pack structure and an assembly process thereof. The battery pack structure comprises a module; the battery pack structure further comprises a water-cooling boxbody, a protection structure arranged on the water-cooling box body and a module mounting assembly arranged in a protection space formed by the water-cooling box body and the protection structure; andthe module is detachably connected with the water-cooling box body through the module mounting assembly. By optimizing the grouping mode of the battery packs, the battery packs are modularized, and the modules are detachable, so that the later maintenance cost of the battery packs is greatly reduced, and the overall cost of the battery packs is reduced.

Owner:芜湖天量电池系统有限公司

High-speed sorting mechanism for batteries

Owner:江苏洛柳精密科技有限公司

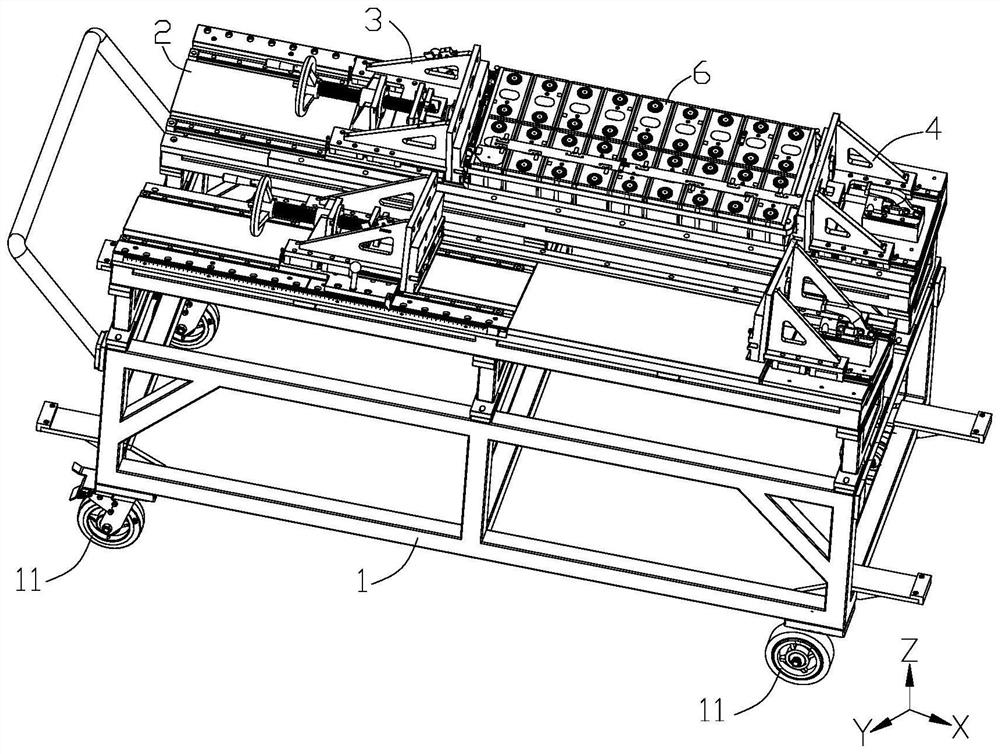

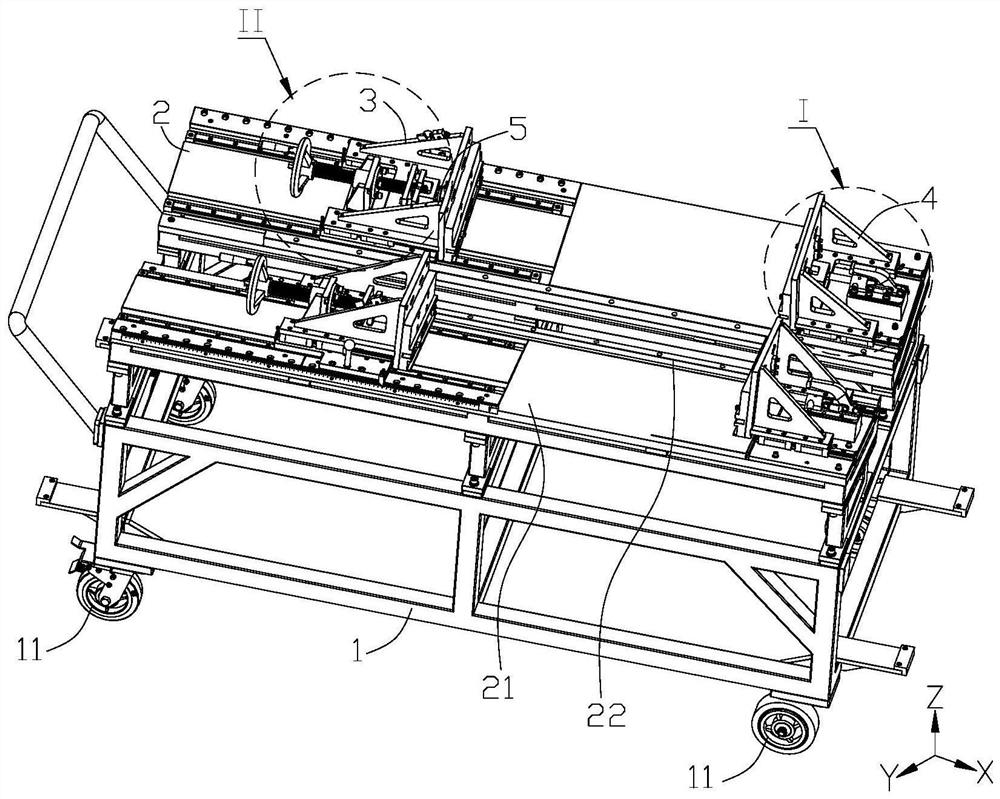

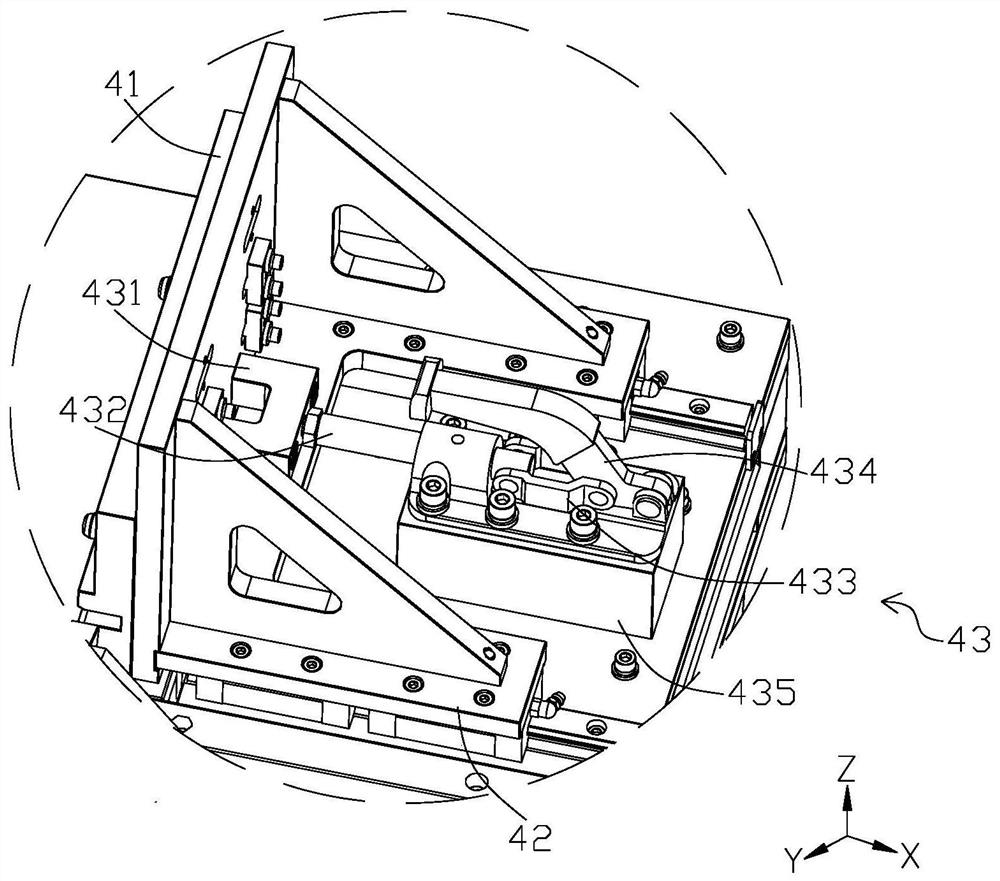

Gift box caser

ActiveCN103274077AImprove cohesionImprove group efficiencyPackagingEngineeringMechanical engineering

The invention provides a gift box caser. The gift box caser comprises a conveying mechanism I, a different-direction grouping mechanism, a conveying mechanism II, an encasing mechanism, a first-stage pushing assembly and a second-stage pushing assembly. The conveying mechanism I is used for conveying products, the different-direction grouping mechanism is used for grouping the products, the conveying mechanism II is used for outputting the products after the products are grouped by the different-direction grouping mechanism, the encasing mechanism is used for encasing the products on the conveying mechanism II, the first-stage pushing assembly is used for pushing the products on the conveying mechanism I to the different-direction grouping mechanism, and the second-stage pushing assembly is used for pushing the products to the conveying mechanism II after the products are grouped by the different-direction grouping mechanism. The gift box caser is capable of outputting two groups of products at a time through the different-direction grouping mechanism, high in grouping efficiency, short in grouping time, good in overall matching of equipment, reasonable in structure and high in encasing efficiency.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Novel graphene-based total-soil metal lithium battery and working method thereof

ActiveCN108321391ALower internal resistanceEasy transferPhosphatesElectrode carriers/collectorsElectrical batteryNew energy

The invention discloses a novel graphene-based total-soil metal lithium battery. The novel graphene-based total-soil metal lithium battery comprises a positive electrode, a negative electrode, solid electrolyte, a diaphragm and a battery shell. In the battery, a positive current collector adopts a LiFePO4-graphene based compound; a negative current collector adopts metal lithium; the diaphragm adopts polypropylene; the solid electrolyte adopts a V2S5-graphene based composite material; the middle of the positive electrode and the solid electrolyte is coated with one layer of the diaphragm; themiddle of the negative electrode and the solid electrolyte is coated with one layer of the diaphragm; the diaphragms are arranged in parallel and are accommodated in the battery shell; the battery isformed by stacking the positive electrode, the negative electrode, the diaphragms and the solid electrolyte in an inserting bag mode; and convex parts on substrates of the positive electrode and the negative electrode are connected with leads to form conductive lugs. The graphene total-soil metal lithium battery reduces the internal resistance of the battery, has excellent electronic conductivity,lithium ion conversation rate and metal lithium rechargeability, improves electrode solid / solid interface contact stability, has high energy density and high safety, and is suitable for a power battery of a new energy automobile.

Owner:ANHUI ANKAI AUTOMOBILE

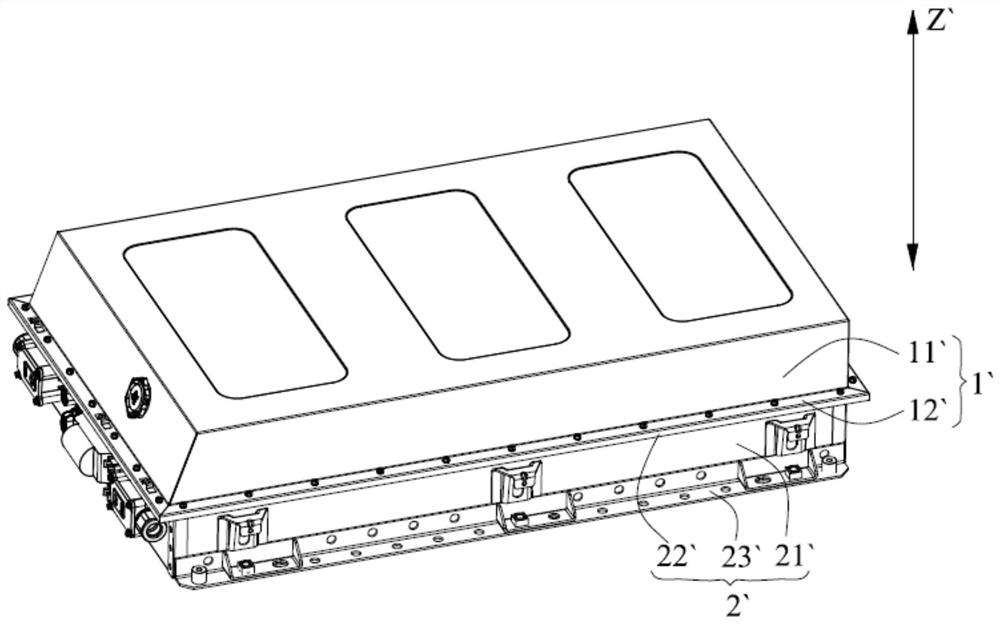

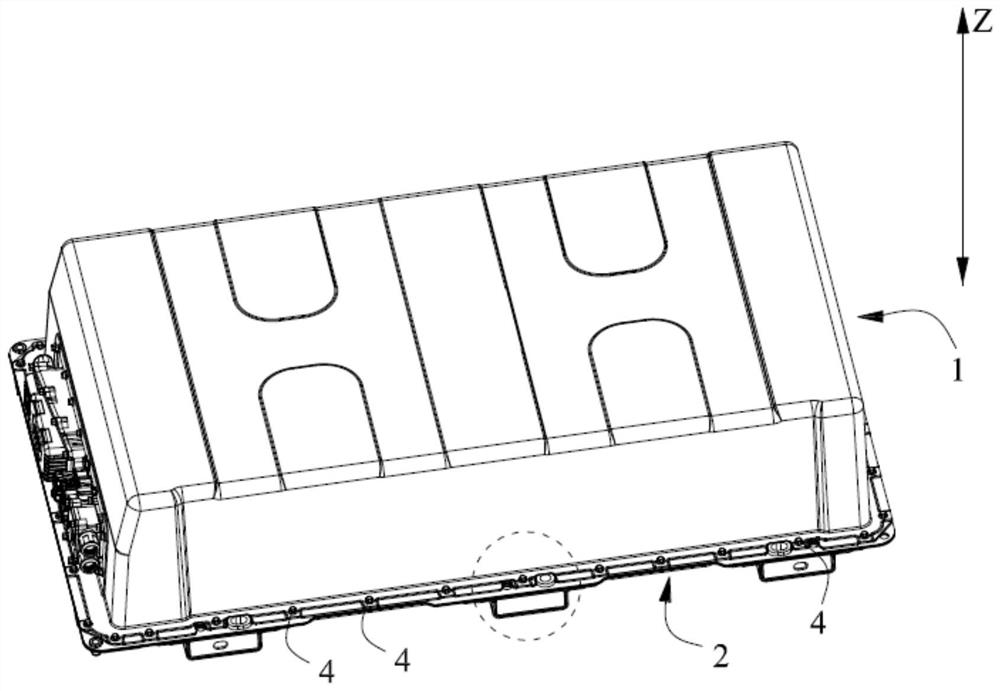

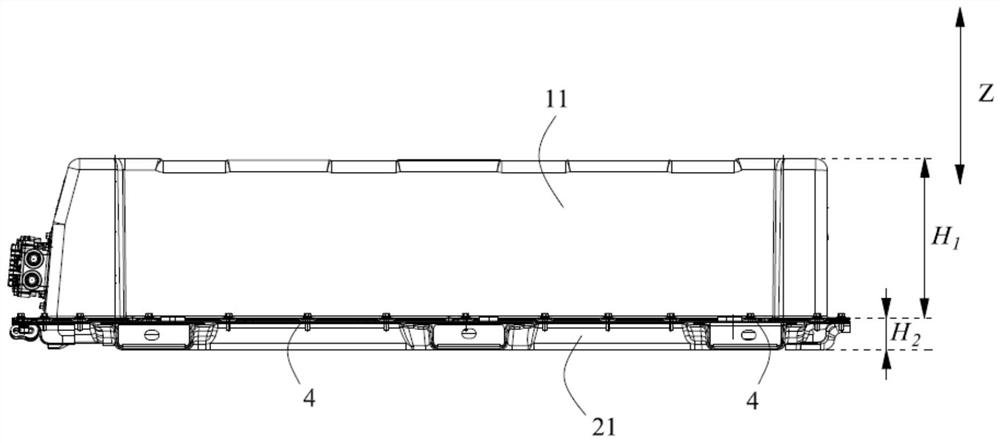

Battery box

ActiveCN113206341AImprove group efficiencyIncrease energy densityElectric propulsion mountingPropulsion by batteries/cellsClassical mechanicsStructural engineering

The invention provides a battery box. The battery box comprises an upper box body, a lower box body, a connecting piece and a fixing piece; the upper box body is provided with a first side wall and a first eave part protruding out of the first side wall in the circumferential direction, and the lower box body is provided with a second side wall and a second eave part protruding out of the second side wall in the circumferential direction. The first eave part and the second eave part are oppositely arranged in the vertical direction, the first eave part is provided with a first connecting hole, and the second eave part is provided with a second connecting hole and a mounting hole spaced from the second connecting hole. And the connecting piece is fixedly connected with the upper box body and the lower box body through the first connecting hole and the second connecting hole. The material density of the lower box body is larger than that of the upper box body, and the height of the first side wall in the vertical direction is larger than that of the second side wall in the vertical direction. According to the battery box provided by the invention, the structure of the lower box body is simplified, and the weight of the lower box body is reduced, so that the grouping efficiency and the energy density of the battery box are improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Large module grouping structure of flexible soft package battery

PendingCN108666494ASolve the generality problemLower component costsCurrent conducting connectionsBatteriesElectrical batteryBusbar

The invention discloses a large module grouping structure of a flexible soft package battery. The large module grouping structure comprises a plurality of Blocks (2) and a plurality of in-module frames (5) which are stacked in a crossed way along the thickness direction, wherein the Blocks (2) and the in-module frames (5) are packaged into groups by means of packing straps (1); the Blocks (2) arebattery modules; positive and negative electrodes of the plurality of Blocks (2) are respectively and electrically connected by means of busbars; the in-module frames (5) are positioned among the Blocks (2), so that the Blocks (2) are adjusted to reserve a certain range of gap from one another, and flexible grouping is further realized. The large module grouping structure of the flexible soft package battery can solve the conflict between module universality and flexible design, reduces grouping cost of the module, and increases the grouping efficiency of the module.

Owner:TIANJIN ENERGIES

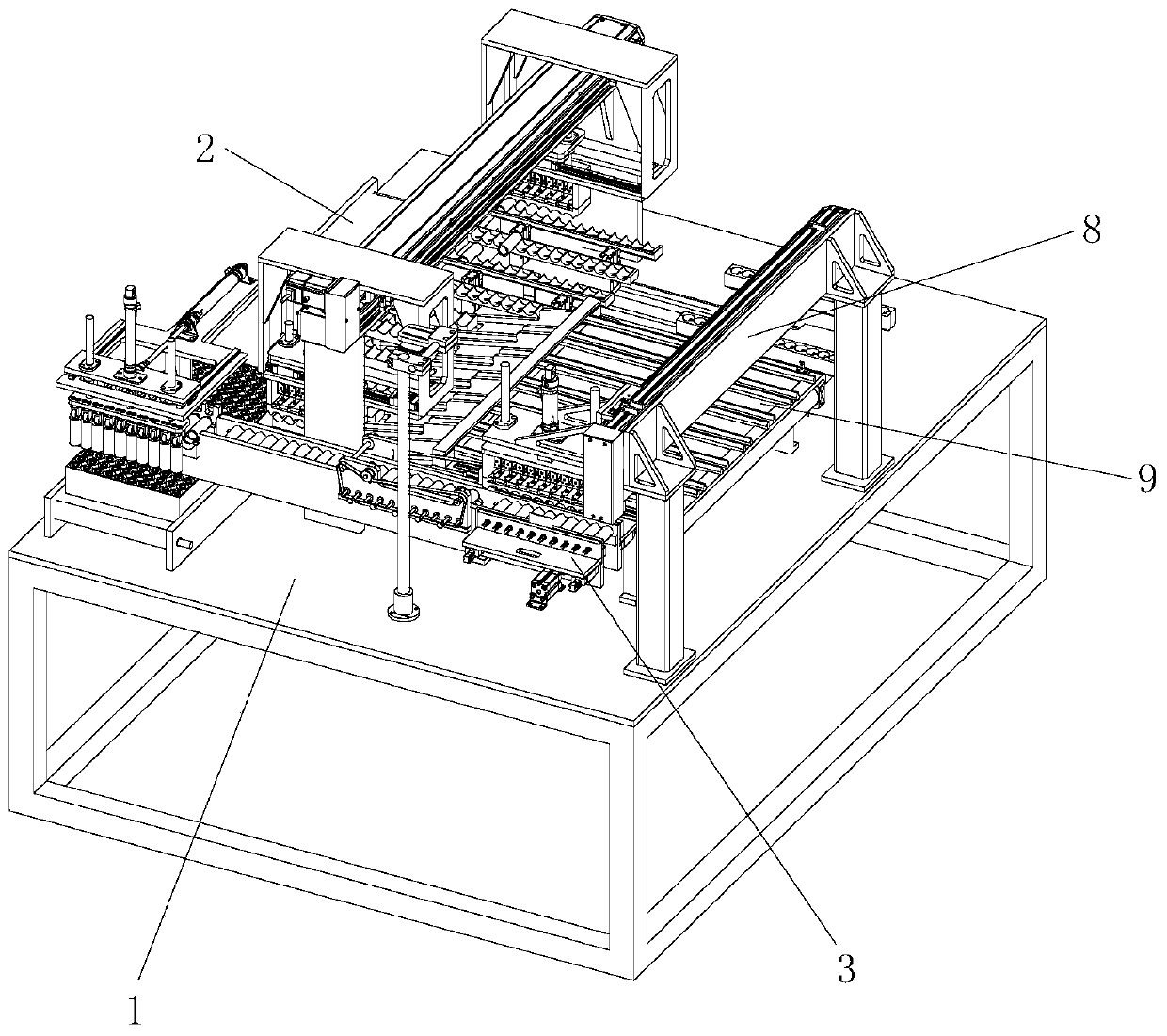

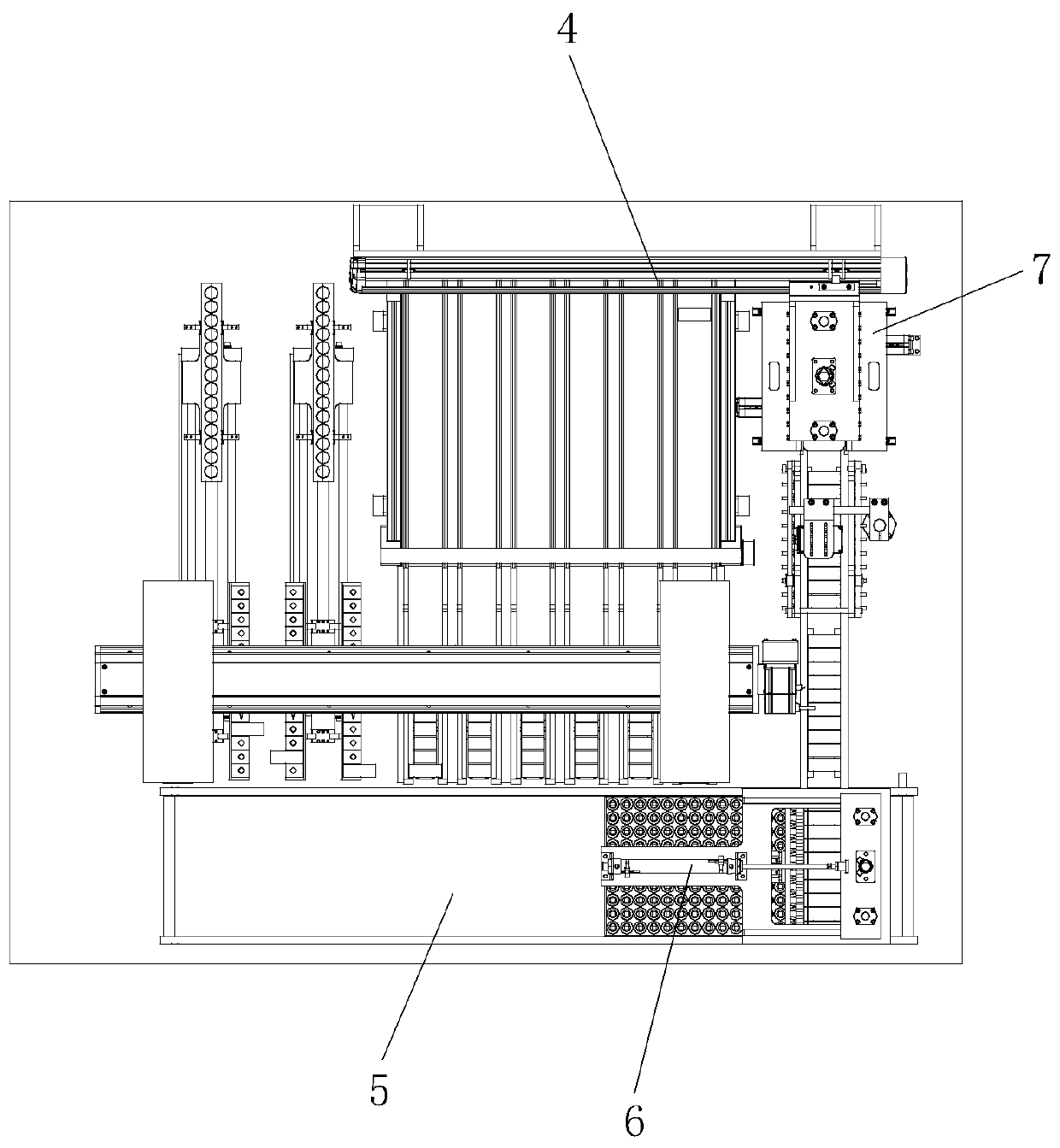

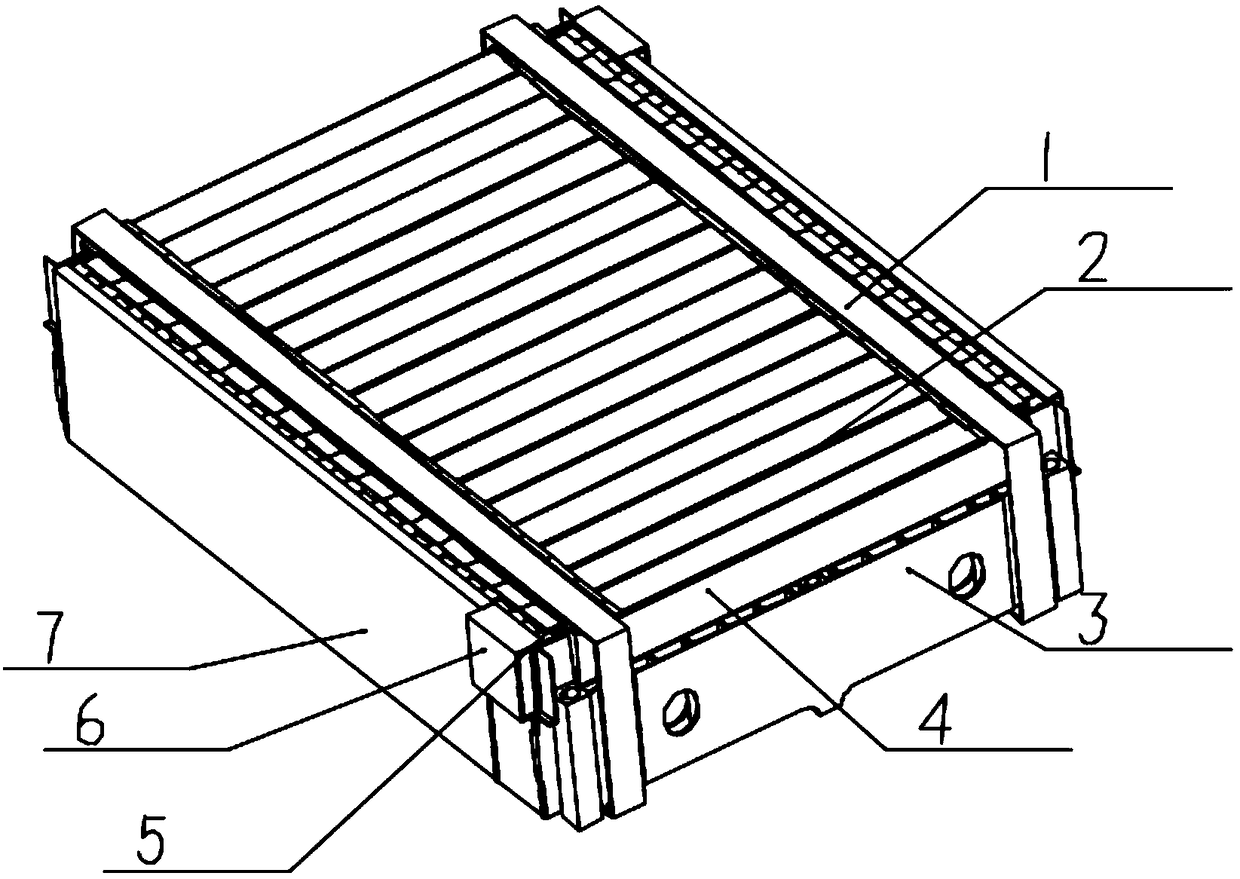

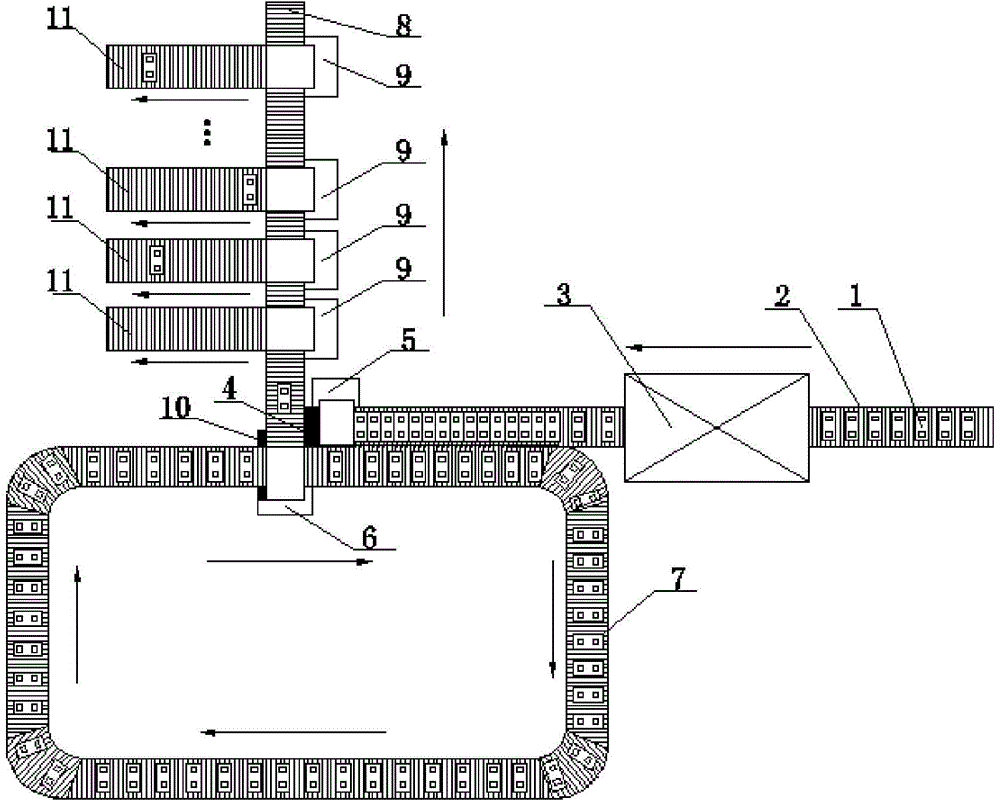

Reverse-flow full-automatic battery grouping method and reverse-flow full-automatic battery grouping system based on dynamic optimization

ActiveCN104914379AReduce the workload of manual matchingReduce labor costsElectrical testingSecondary cells servicing/maintenanceGroup methodEngineering

The invention discloses a reverse-flow full-automatic battery grouping method and a reverse-flow full-automatic battery grouping system based on dynamic optimization. The battery grouping system comprises a battery performance detection device, a conveying device, and a main control computer. In the conveying device, an input conveyor belt and one side of an annular conveyor belt are parallel to and connected with each other, the annular conveyor belt and an output conveyor belt are perpendicular to and connected with each other, and the output conveyor belt and an outlet conveyor belt are perpendicular to and connected with each other. A baffle, a push-in cylinder and a photoelectric door are arranged at the tail end of the input conveyor belt. A push-out cylinder and a photoelectric door are arranged at the joint of the annular conveyor belt and the output conveyor belt, and a sensor is arranged beside the push-out cylinder. The distance between the push-out cylinder and the push-in cylinder is equal to the spacing between two adjacent batteries on the annular conveyor belt. The battery grouping method comprises the steps of battery input and grouping optimization calculation, battery pushing-out, and battery grouping output. By adopting the battery grouping method and the battery grouping system, real-time grouping optimization selection can be carried out according to the current state, and the quality and success rate of grouping are improved.

Owner:浙江海宁经编产业园区开发有限公司

User group optimization method and device, storage medium and computer equipment

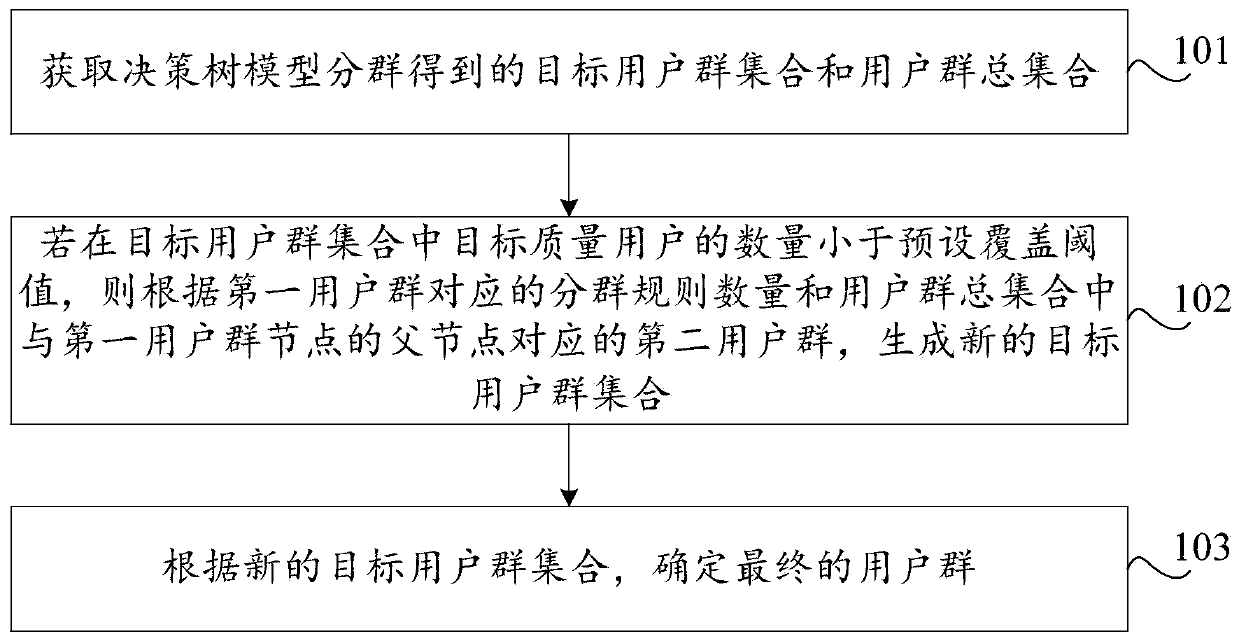

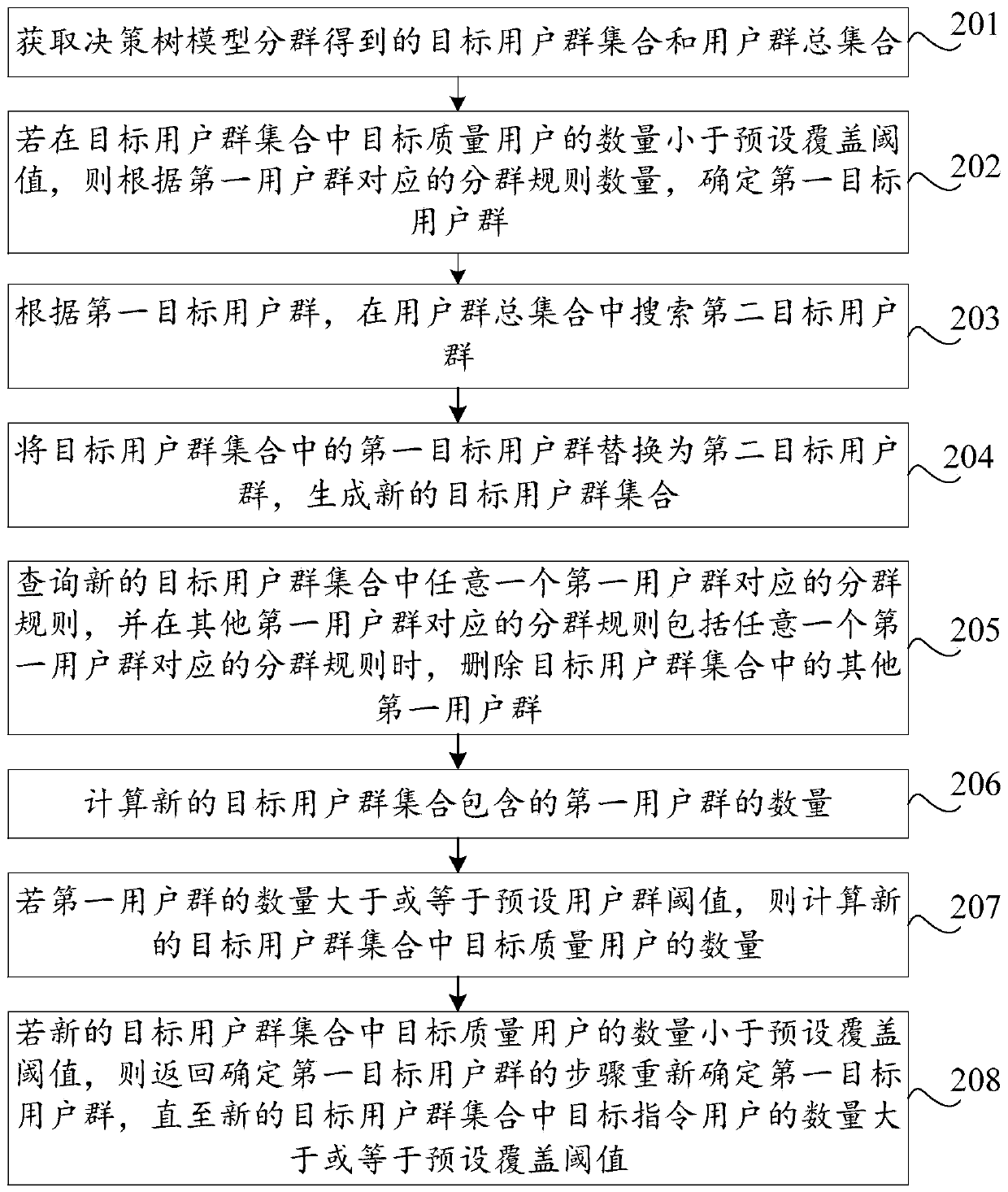

ActiveCN109992699AOptimization is fast and accurateImprove group efficiencyCharacter and pattern recognitionOther databases retrievalRelationship - FatherComputer science

The invention discloses a user group optimization method and device, a storage medium and computer equipment. The method comprises the steps that a target user group set and a user group total set obtained by clustering a decision tree model are acquired, the target user group set comprises a first user group corresponding to each leaf node of the decision tree model, and the user group total setcomprises a second user group corresponding to each node of the decision tree model; if the number of the target quality users in the target user group set is smaller than a preset coverage thresholdvalue; if so, a new target user group set is generated according to the number of grouping rules corresponding to the first user group and a second user group corresponding to the father node of the first user group node in the user group total set, wherein the number of target quality users in the new target user group set is greater than or equal to a preset coverage threshold; and a final usergroup is determined according to the new target user group set. The user group optimization method is simple and effective.

Owner:PING AN TECH (SHENZHEN) CO LTD

Assembling device and assembling method

PendingCN112310462AHigh positioning accuracyAvoid correctionPrimary cell to battery groupingAssembling battery machinesStructural engineeringMechanical engineering

The invention relates to an assembling device and an assembling method, which are used for stacking a plurality of battery units, the stacking direction being the length direction of the assembling device. The assembling device comprises a base and an assembling part; the assembling part is mounted on the base and comprises a first matching surface and a second matching surface; the first matchingsurface is used for placing a battery unit; in the direction close to the second matching surface, the first matching surface inclines downwards by a first preset angle alpha, so that the battery unit placed on the first matching surface can move towards the direction of the second matching surface and abuts against the second matching surface. In the stacking process of the battery units, the battery units can be firstly positioned, other driving mechanisms do not need to be additionally arranged in the positioning process, and the positioning can be realized only through the structures of the battery units and the assembling part, so that the position precision of the battery units can be improved; and the positions of the battery units are prevented from being corrected in the stackingprocess, and therefore, the grouping efficiency of the battery units is improved, and meanwhile, the assembling device can be simplified.

Owner:CONTEMPORARY AMPEREX TECH CO

Application icon management method and device

ActiveCN107817927AEasy to operateImprove group efficiencyInput/output processes for data processingComputer terminalTouchscreen

Owner:PING AN TECH (SHENZHEN) CO LTD

Battery cell, battery module and vehicle

PendingCN113258207ALarge capacityImprove group efficiencySecondary cellsCell component detailsPower batteryMechanical engineering

The invention relates to the technical field of power batteries, and discloses a battery cell, a battery module and a vehicle. The battery cell comprises a metal shell, a naked battery cell and an external tab; the metal shell comprises a packaging shell and a sealing cover, a sealing cavity is defined between the packaging shell and the sealing cover, and connecting positions are arranged at the connecting position between the packaging shell and the sealing cover in the circumferential direction and comprise the first connecting position formed through heat sealing or mucilage glue and the second connecting position formed through welding; a glue part is arranged between the sealing cover at the first connecting position and the packaging shell; the naked battery cell is arranged in the sealing cavity; and one end of the external tab is arranged in the sealing cavity and is electrically connected to the naked battery cell, the other end of the external tab penetrates out of the metal shell, and the external tab is in insulated connection with the metal shell. According to the invention, the directional pressure relief of the battery cell is realized, the occurrence probability of battery cell explosion is reduced, and the safety of the battery module is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com