Method for analyzing lithofacies of powder samples

A technology of petrographic analysis and powder, which is applied in the field of petrographic analysis of powder samples, can solve problems such as petrographic analysis of powdery materials, and achieve the effect of studying grindability and improving the efficiency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

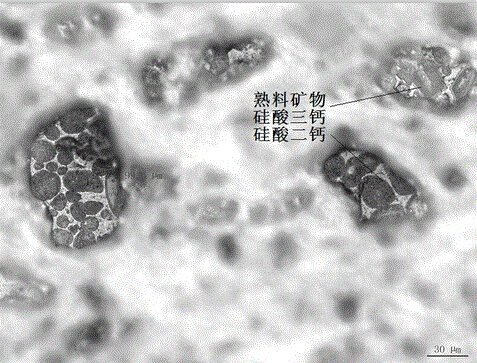

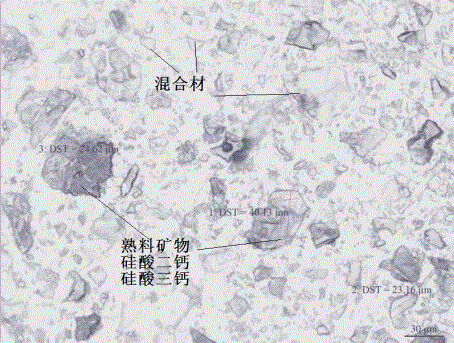

Image

Examples

Embodiment 1

[0038] A petrographic analysis method of a powder sample, including six steps of sample mounting, rough grinding, fine grinding, polishing, erosion and petrographic analysis. Before the sample mounting, the powder sample is added to the sulfur that has been heated and melted in advance. After stirring evenly and standing for 3 minutes, the conventional sample mounting, rough grinding, fine grinding, polishing, etching and petrographic analysis steps are carried out; in this example, the mixing volume ratio of molten sulfur to powder sample is 0.1:1.

Embodiment 2

[0040] A petrographic analysis method for powder samples, including six steps of sample mounting, rough grinding, fine grinding, polishing, erosion and petrographic analysis. Before mounting the samples, the powder samples are added to the liquid resin with a curing agent, After stirring evenly, after standing still for 15 minutes, carry out conventional sample mounting, rough grinding, fine grinding, polishing, etching and petrographic analysis steps.

[0041] In this embodiment, the mixing volume ratio of the liquid resin with the curing agent and the powder sample is 0.5:1, the curing agent is ethylenediamine, and the liquid resin is epoxy resin; the mixing ratio of the curing agent and the liquid resin is 0.1:1.

[0042] Described sample mounting, coarse grinding, fine grinding, polishing, erosion and petrographic analysis, the specific steps are as follows:

[0043] (1) Mounting

[0044] Put the lump material into the mold, and import the liquid resin with curing agent,...

Embodiment 3

[0056] A petrographic analysis method for powder samples, including six steps of sample mounting, rough grinding, fine grinding, polishing, erosion and petrographic analysis. Before mounting the samples, the powder samples are added to the liquid resin with a curing agent, After stirring evenly, after standing for 10 minutes, carry out conventional sample mounting, coarse grinding, fine grinding, polishing, etching and petrographic analysis steps; in this embodiment, the mixing volume ratio of liquid resin with curing agent and powder sample 0.3:1, the curing agent is ethylenediamine, and the liquid resin is epoxy resin; the mixing ratio of the curing agent and liquid resin is 0.4:1.

[0057] Described sample mounting, coarse grinding, fine grinding, polishing, erosion and petrographic analysis, the specific steps are as follows:

[0058] (1) Mounting

[0059] Put the lump material into the mold, and introduce it into the liquid resin with curing agent. The curing agent is et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com