Pumping well monitoring system and monitoring method

A monitoring system and pumping well technology, applied in the field of pumping well monitoring, can solve problems such as pump leakage, floating valve leakage, and damage to pumping well equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

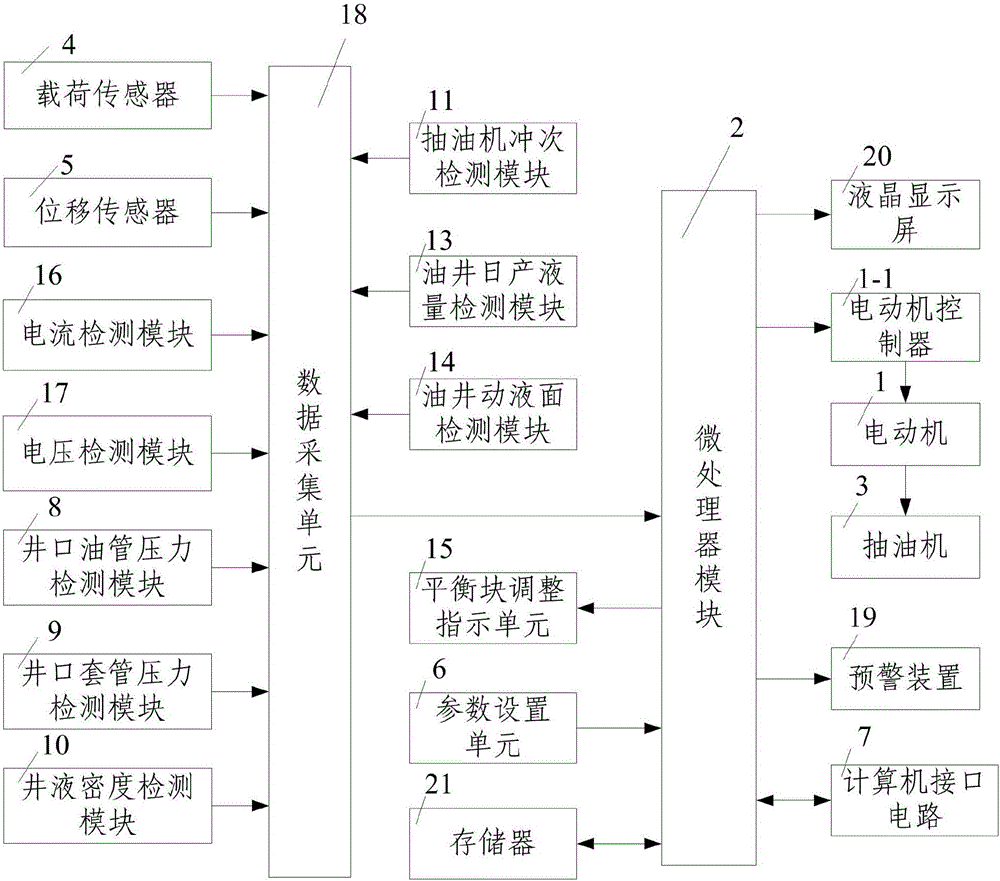

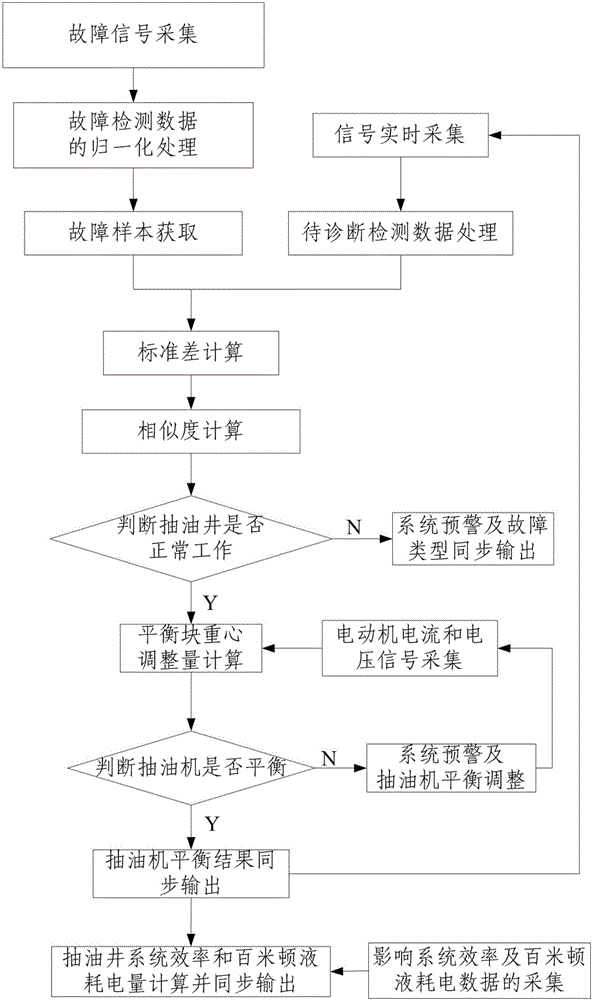

[0099] like figure 1 A pumping well monitoring system shown includes a monitoring device, a pumping unit 3 and an electric motor 1 for driving the pumping unit 3 to pump oil. The monitoring device includes a microprocessor module 2 and a microprocessor module 2 The connected memory 21, the motor controller 1-1 for controlling the motor 1 and the pumping well detection module for detecting the working condition of the monitored pumping well, the input terminal of the microprocessor module 2 is connected with a data acquisition unit 18 and a parameter setting unit 6 for parameter setting, the output terminal of the microprocessor module 2 is connected with a liquid crystal display 20, an early warning device 19 and a balance weight adjustment indicating unit 15, and the motor controller 1-1 and The microprocessor module 2 is connected, and the motor controller 1-1 is controlled by the microprocessor module 2;

[0100] The pumping well detection module includes a wellhead tubing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com