Busbar-free battery module, busbar-free battery module assembling method and battery pack

A battery module and assembly method technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of low assembly efficiency, large number of parts, and complex assembly, so as to improve installation efficiency and assembly efficiency , reduce the overall weight, and reduce the number of assembly parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

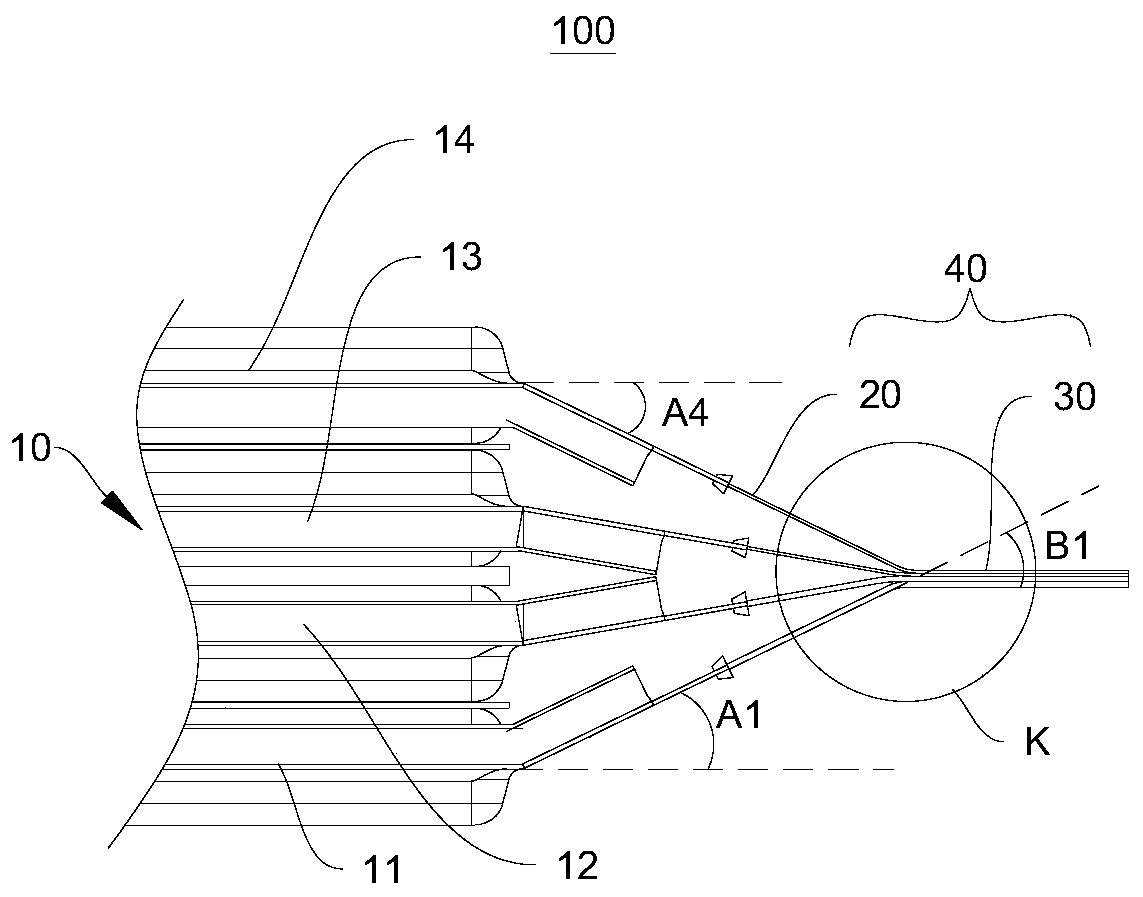

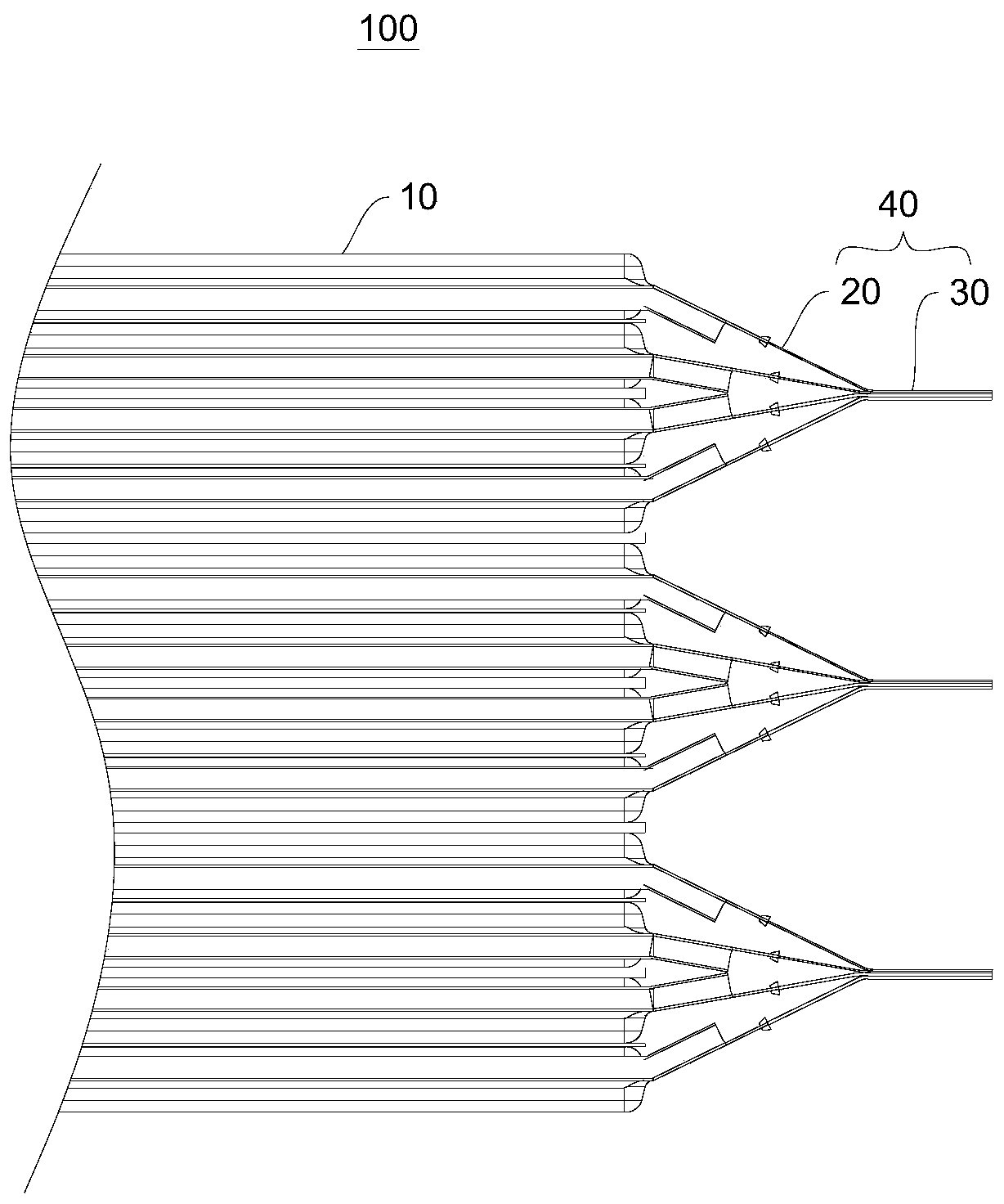

[0053] figure 1 For a structural schematic diagram of the bus-less battery module 100 provided in the first embodiment of the present invention, please refer to figure 1 .

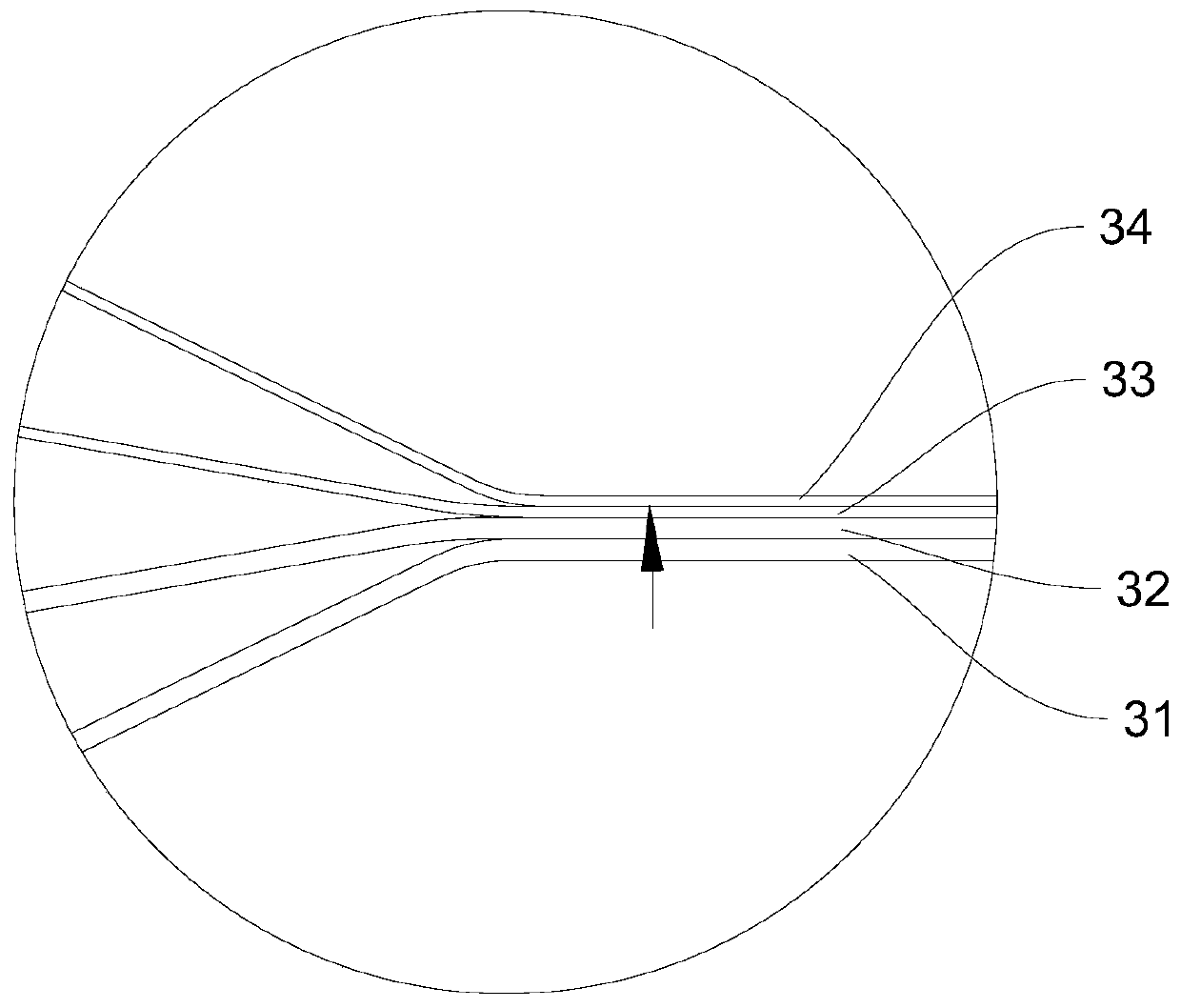

[0054] An embodiment of the present invention provides a bus-barless battery module 100 , including a plurality of battery cells 10 , and each battery cell 10 is provided with a connecting tab 40 . Each connecting tab 40 includes a first segment 20 and a second segment 30, the first segment 20 is connected to the battery 10, and the first segment 20 is bent at a first preset angle relative to the battery 10; the second The segment 30 is connected to an end of the first segment 20 away from the battery cell 10 , and the second segment 30 is bent at a second predetermined angle relative to the first segment 20 . The plurality of second segments 30 all extend along the same direction, and the plurality of second segments 30 are welded. The connecting tabs 40 of each battery cell 10 are directly overlapped....

no. 2 example

[0070] Figure 4 For the schematic diagram of the steps of the assembly method of the bus-less battery module 100 provided in the second embodiment of the present invention, please refer to Figure 4 .

[0071] The second embodiment of the present invention provides a bus-barless battery module 100 assembly method, the assembly method mainly includes the following steps:

[0072] S10: Bending and connecting the tab 40 . Each cell 10 is provided with a connecting tab 40 , and one end of each connecting tab 40 close to the cell 10 is bent along a first preset angle to form a first segment 20 ; the first segment 20 is far away from the cell 10 One end of one end is bent along a second predetermined angle to form a second segment 30; and a plurality of second segments 30 all extend along the same direction.

[0073] In this embodiment, the plurality of electric cores 10 includes four electric cores 10, the connecting tabs 40 of the first electric core 11 and the second electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com