Multi-lug cell, multi-terminal battery, battery module and preparation method thereof

A battery module and multi-tab technology, which is applied in the field of multi-tab cells, battery modules and their preparation, and multi-terminal batteries, can solve problems such as potential safety hazards and rapid battery temperature rise, and achieve enhanced overcurrent capability and reduced Internal resistance, enhanced heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

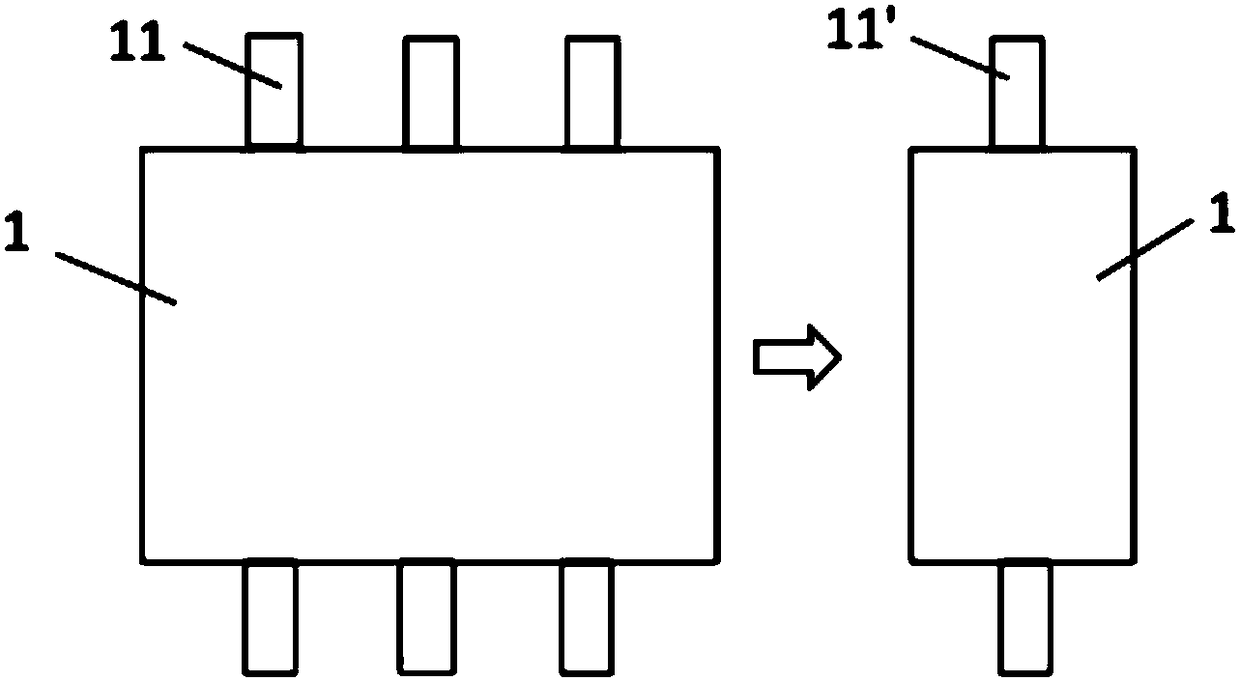

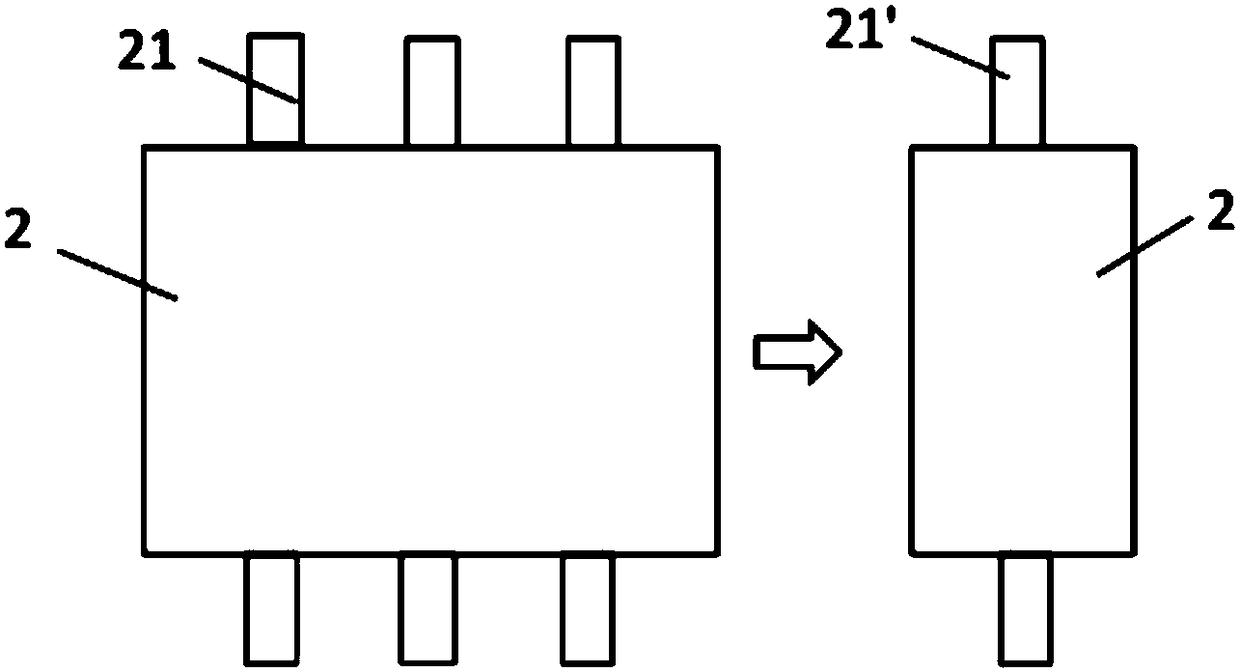

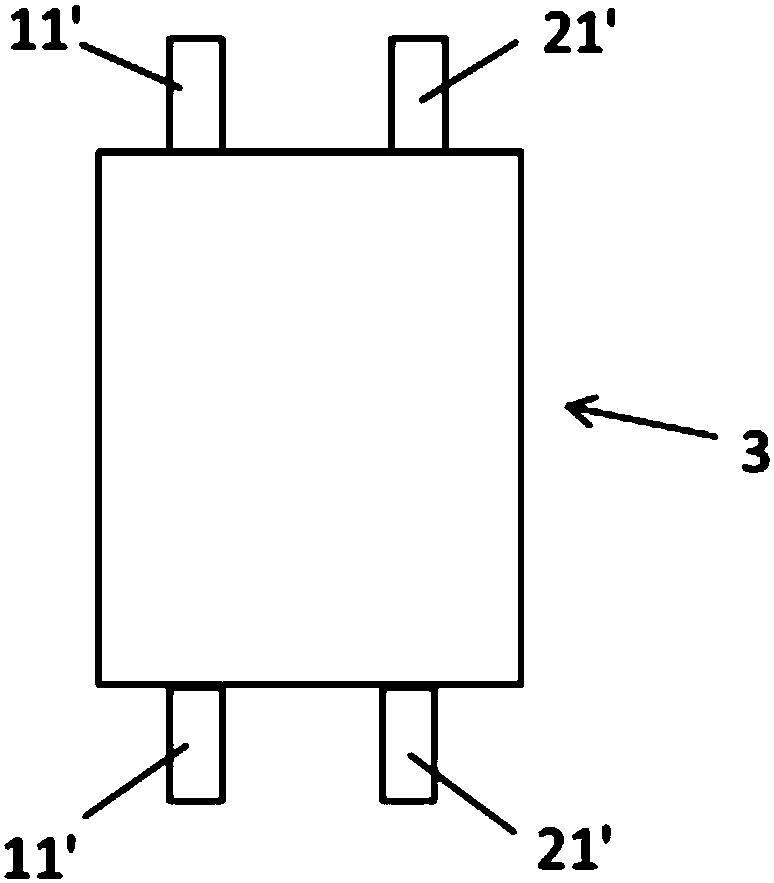

[0046] Such as Figure 1~3 As shown, a multi-tab battery cell includes a battery cell 3 formed by winding a positive electrode sheet 1, a diaphragm and a negative electrode sheet 2. Several corresponding positive electrode ears 11 are arranged on both sides of the positive electrode sheet 1, and two negative electrode sheets 2 are provided. There are several corresponding negative tabs 21 on the side; the positive tabs 11 on both sides of the positive sheet 1 are wound to form the positive tabs 11' on both sides of the cell 3; the negative tabs 21 on both sides of the negative sheet 2 are wound The negative tabs 21 ′ on both sides of the battery cell 3 are formed.

[0047] Preferably, the thickness of the positive tab 11 is 3-20 μm, and the thickness of the negative tab 21 is 3-20 μm.

[0048] Preferably, the thickness of the positive electrode sheet 1 is 30-100 μm, and the thickness of the negative electrode sheet 2 is 50-150 μm.

[0049] Preferably, the thickness of the ba...

Embodiment 2

[0052] Such as Figure 3-5 As shown, the difference from Example 1 is that this implementation includes a battery cell 3 formed by laminating the positive electrode sheet 1, the separator and the negative electrode sheet 2. Several corresponding positive electrode ears 11 are arranged on both sides of the positive electrode sheet 1, and the negative electrode There are several corresponding negative tabs 21 on both sides of the sheet 2; the positive tabs 11 on both sides of the positive sheet 1 are laminated to form the positive tabs 11' on both sides of the cell 3; the negative tabs 21 on both sides of the negative sheet 2 are The negative tabs 21 ′ on both sides of the battery core 3 are formed after lamination.

[0053] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0063] Such as Figure 6~7 As shown, a multi-terminal battery includes a battery cell 3, a housing 4 for containing the battery cell 3, and a cover plate 5 arranged at both ends of the housing 4. The cover plate 5 includes a first cover plate 51 and a second cover plate 52, the first cover plate 51 and the second cover plate 52. Both the cover plate 51 and the second cover plate 52 are provided with an explosion-proof valve 53, and both the first cover plate 51 and the second cover plate 52 are provided with at least one positive terminal 54 and at least one negative terminal 55, the positive terminal 54 is connected to the cell 3 The positive tab set 11 ′ is electrically connected to the positive tab set 11 ′, and the negative terminal 55 is electrically connected to the negative tab set 21 ′ of the cell 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com