Large module grouping structure of flexible soft package battery

A technology of pouch battery and group structure, which is applied in the direction of battery pack parts, batteries, structural parts, etc., can solve the problems of poor versatility of special-shaped large modules, rising cost of assembly, and inability to meet the needs of low-cost general design, etc. Achieve the effects of improving group efficiency, good versatility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

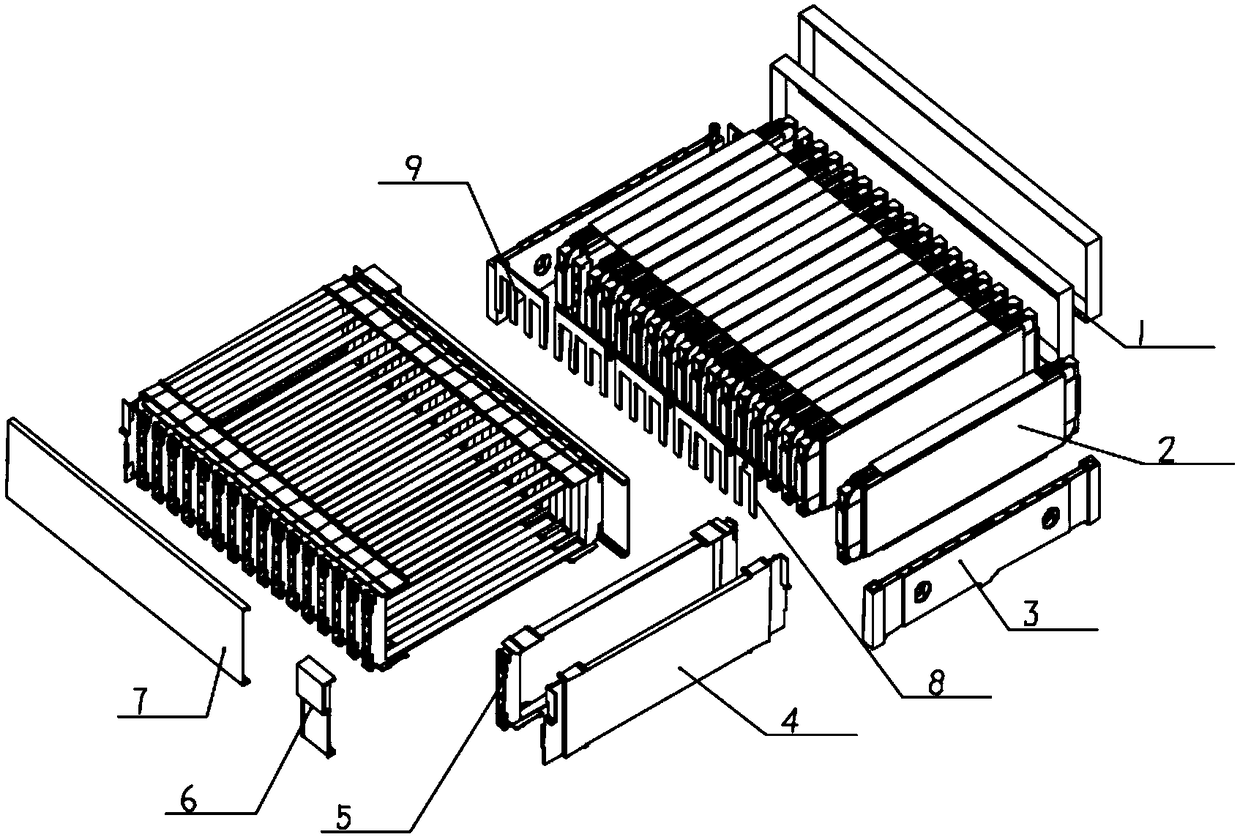

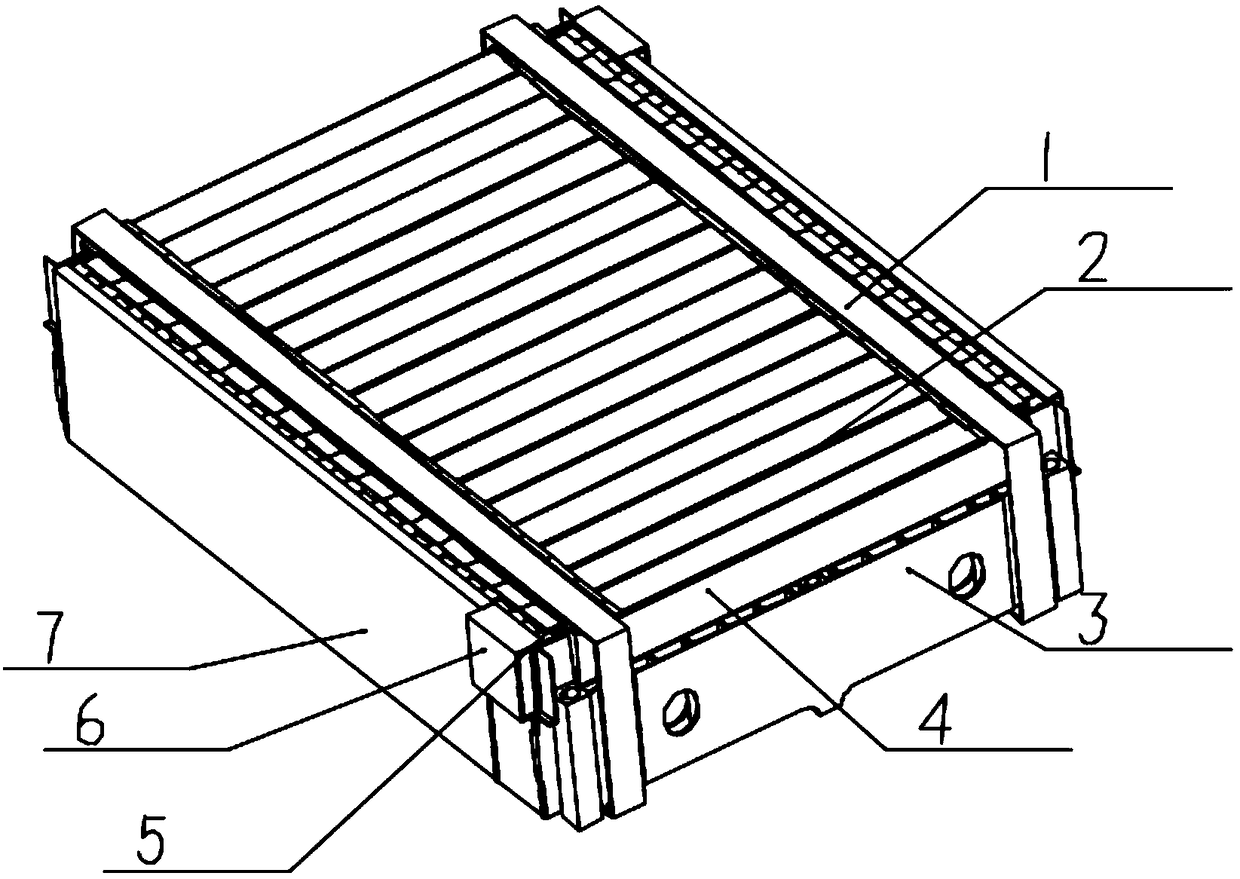

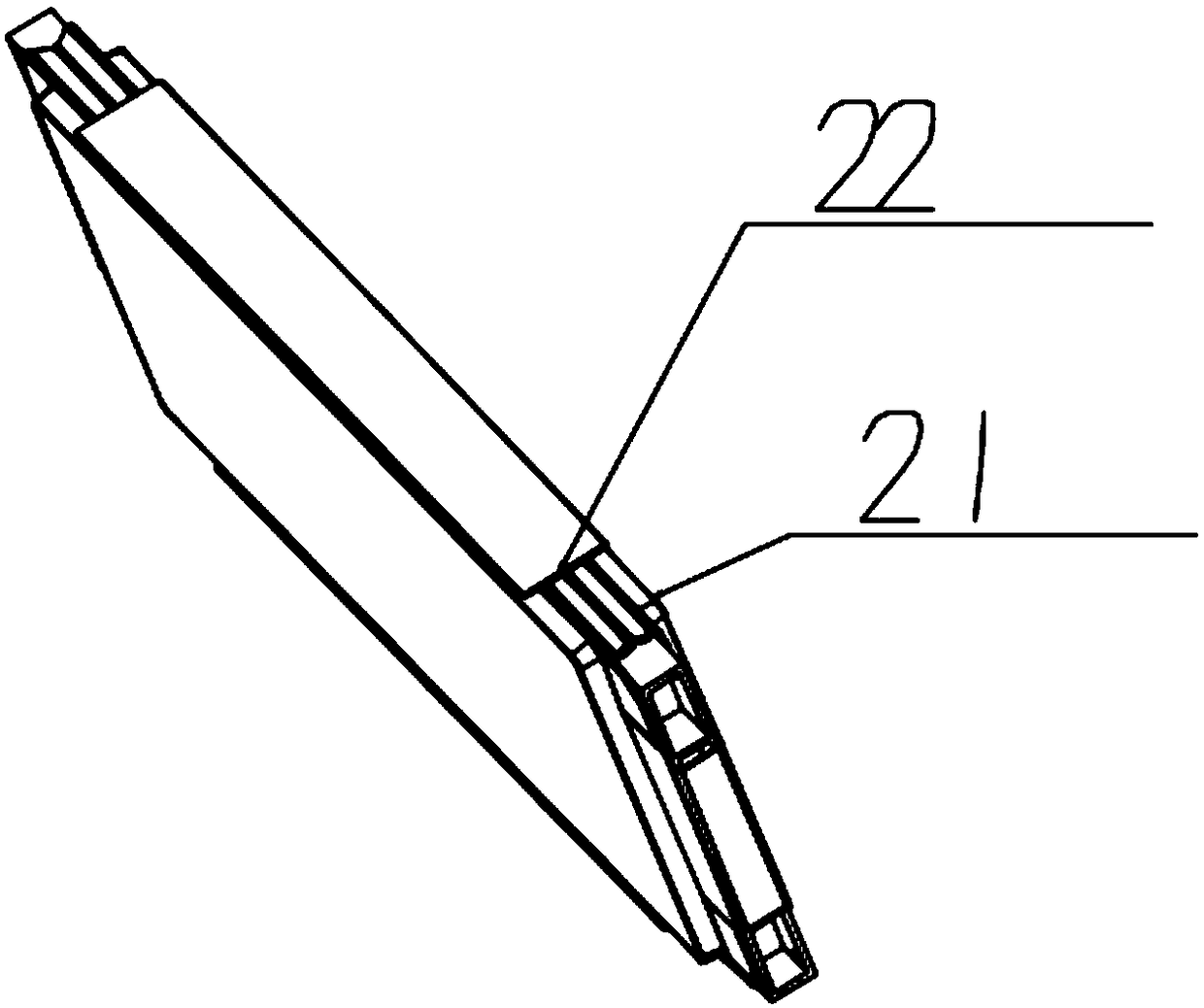

[0030] like figure 1 , 2 As shown, a flexible soft bag large module provided by the present invention includes: packing belt 1, Block2, module end plate 3, module side frame 4, module middle frame 5, pole cover 6, module cover plate 7. Pole busbar 8. Module busbar 9. Two module end plates 3, two module side frames 4, multiple Blocks 2 and multiple module middle frames 5 are stacked along the thickness direction and packed into groups with packing tape. By adjusting the thickness of the frame in the module, a gap of 0.2-0.5mm is reserved between Block2, and the module can be flexibly grouped along the thickness direction of the battery cell.

[0031] The module bus bar 9 and pole bus bar 8 are connected to the electrodes of Block2 by welding to realize the series-parallel connection between Block2. Realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com