Vertical laminated optical path module and multi-die semiconductor laser

A technology of semiconductors and lasers, applied in the field of lasers, can solve problems such as difficult mass production of multi-die semiconductor lasers, inability to guarantee product process repeatability, poor disassembly, etc. Effect of space utilization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0057] The invention modularizes the unit devices in the semiconductor laser, and vertically distributes multiple optical paths on the heat sink module in order to fully utilize the space utilization rate to form a vertical stacked optical path module.

[0058] Example 1 of vertically stacked optical path module

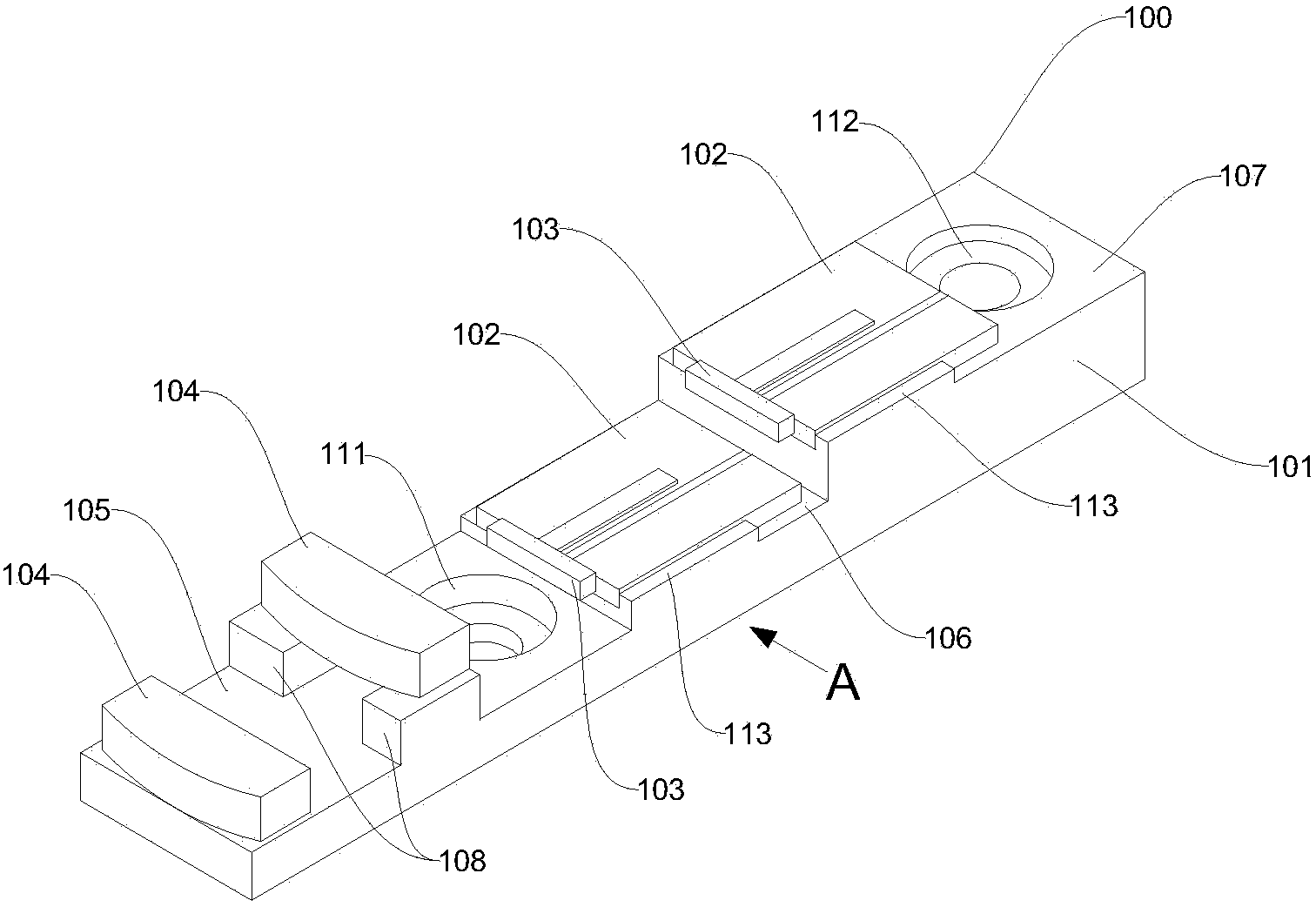

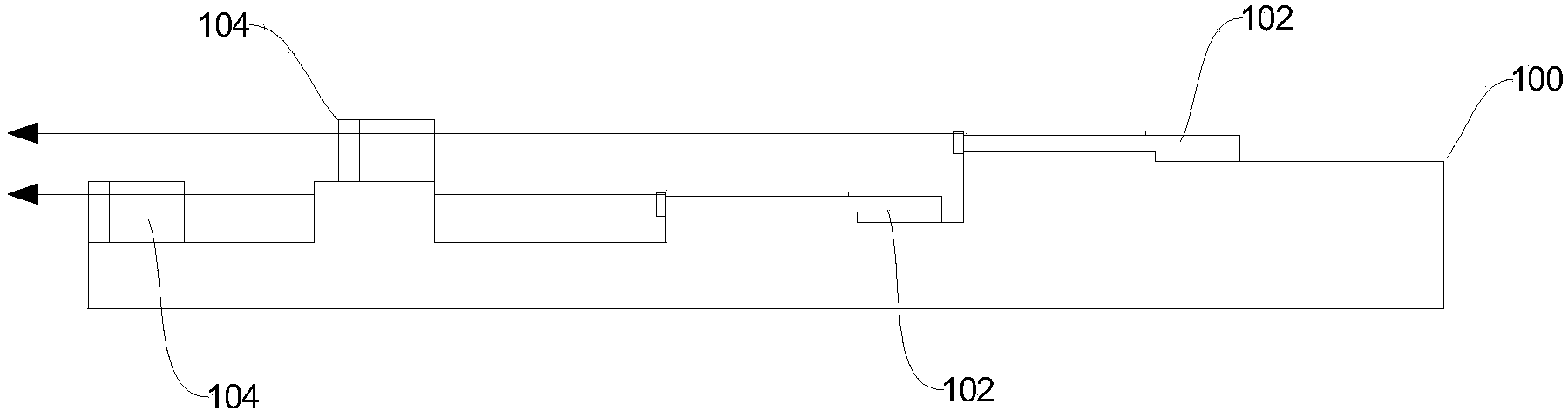

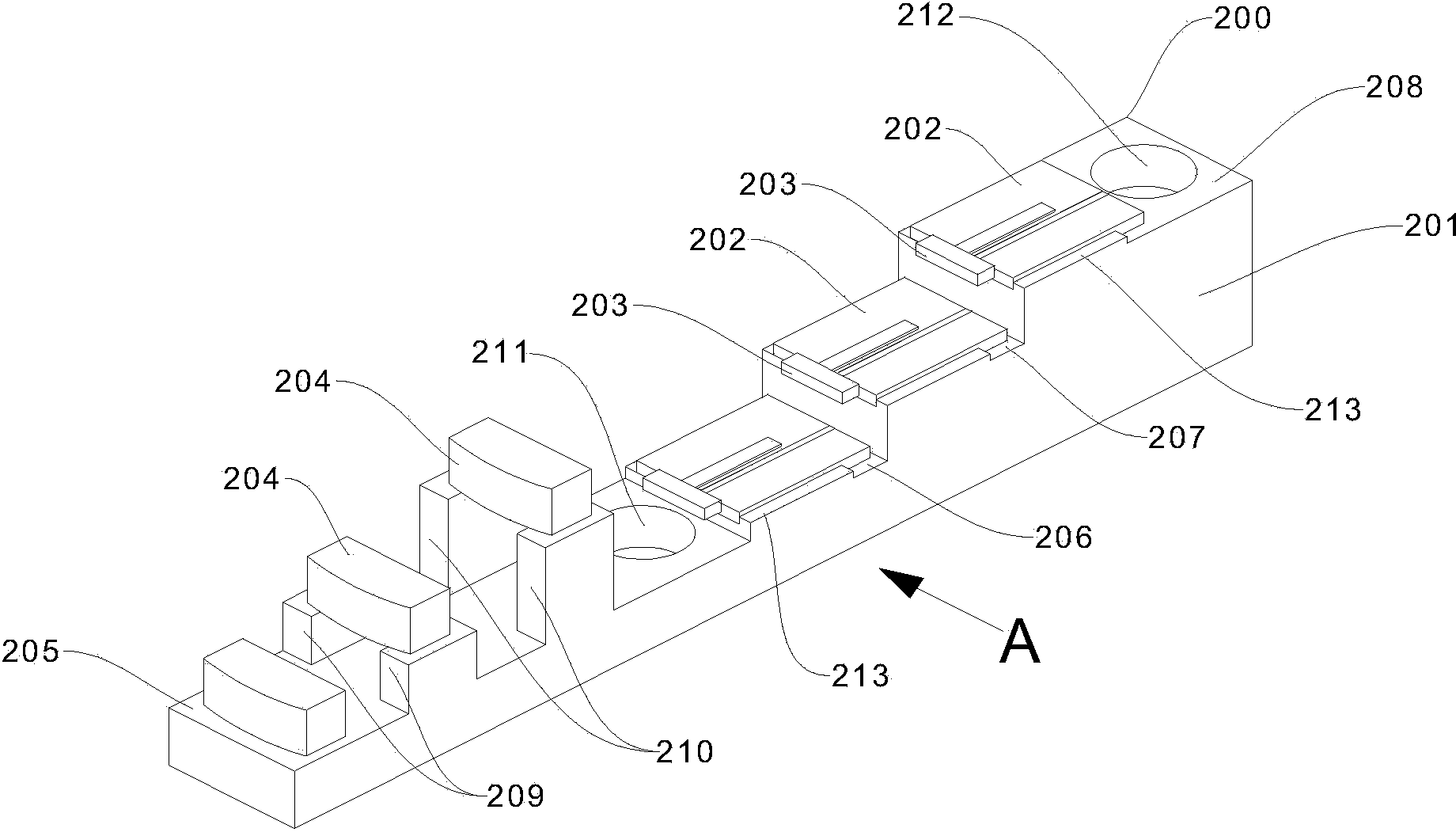

[0059] figure 1 It is a structural schematic diagram of Embodiment 1 of the vertical stacked optical path module in the present invention; figure 2 It is an A-direction view of Embodiment 1 of the vertically stacked optical path module in the present invention. Such as figure 1 and figure 2 As shown, the present invention discloses a vertical stacked optical path module 100, including: a heat sink module 101 and two opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com