Synchronous material trolley conveying device on automobile cluster producing line

A material trolley, automotive instrument technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as increasing the risk of workers, affecting work efficiency, affecting workers' working environment, etc., to reduce Labor cost, less space occupation, and the effect of improving workers' operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0020] Such as figure 1 , Figure 2, image 3 Shown:

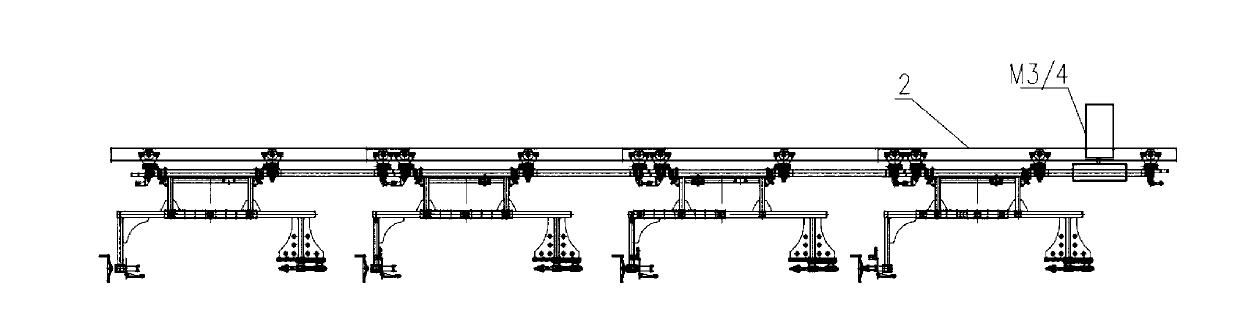

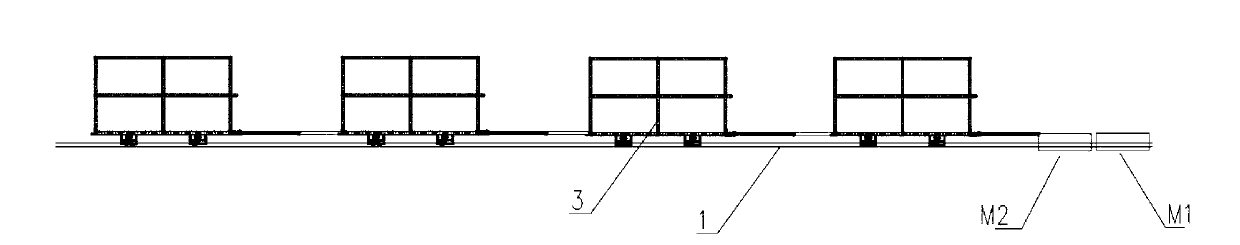

[0021] A synchronous material trolley conveying device on an automobile instrument production line, comprising an instrument production line track 2, a third friction drive device M3, a fourth friction drive device M4, and a material trolley running track 1, a material trolley 3, and a first friction drive device M1, the second friction drive device M2 and a control system.

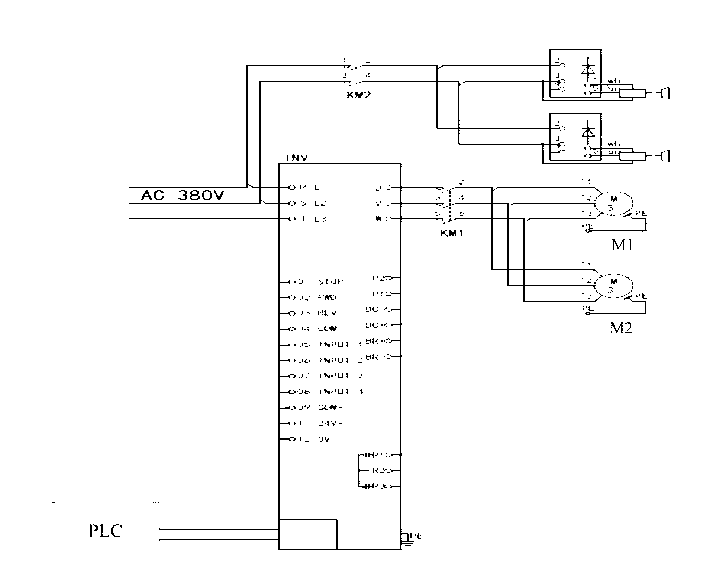

[0022] The control system includes a PLC (that is, a programmable logic controller), a first network-connected frequency converter and a second network-connected frequency converter, and the PLC is electrically connected to the first network-connected frequency converter and the second network-connected frequency converter; the first network-connected frequency converter The frequency converter is electrically connected to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com