Novel power battery pack structure and assembly process thereof

A technology for power battery packs and battery packs, applied in battery pack components, batteries, structural parts, etc., can solve the problems of large loss of energy density in battery pack production, low battery pack production efficiency, and complex assembly processes, and achieve the goal of providing cost-effective solutions. Group efficiency, avoid energy conversion losses, reduce the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

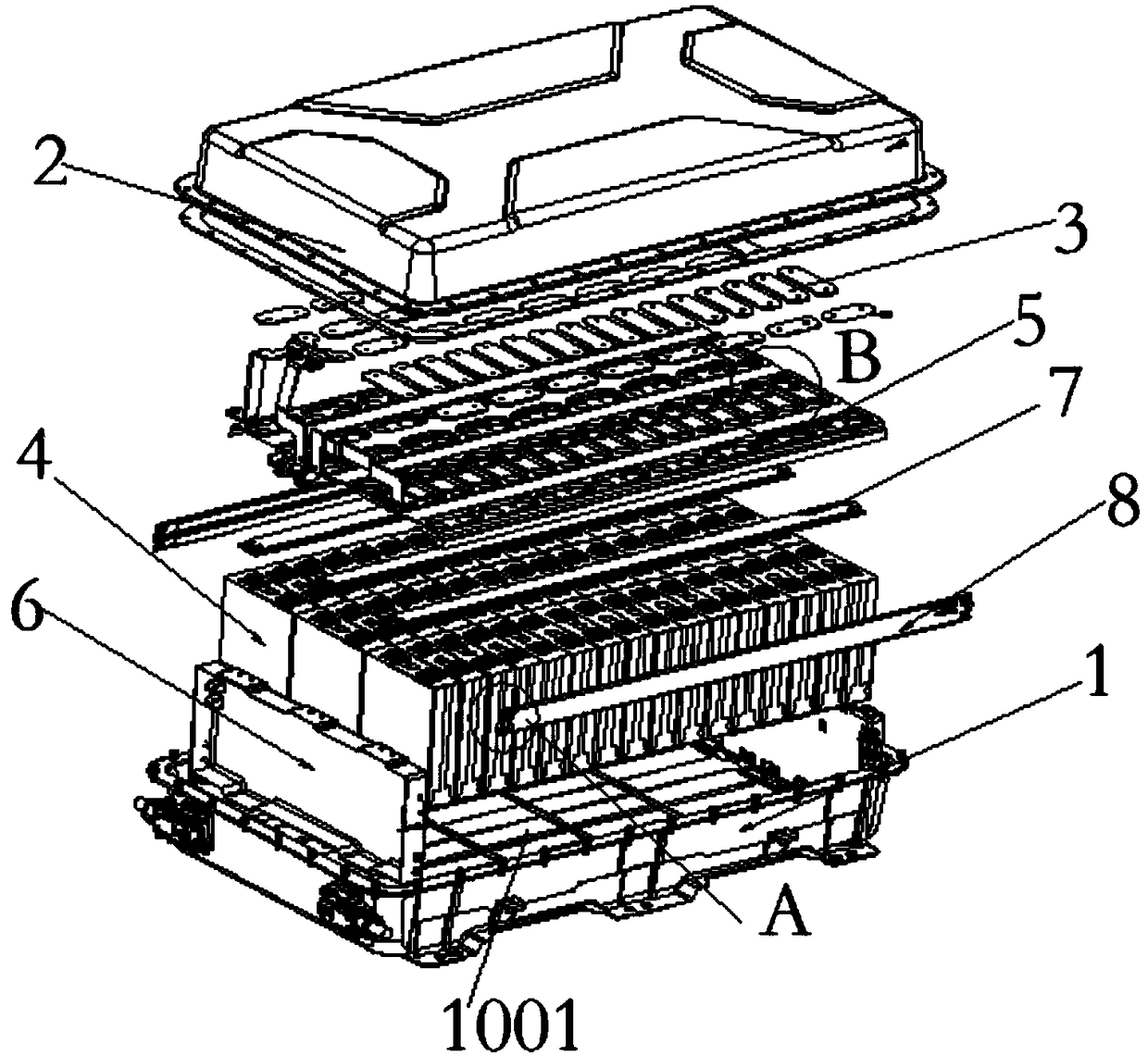

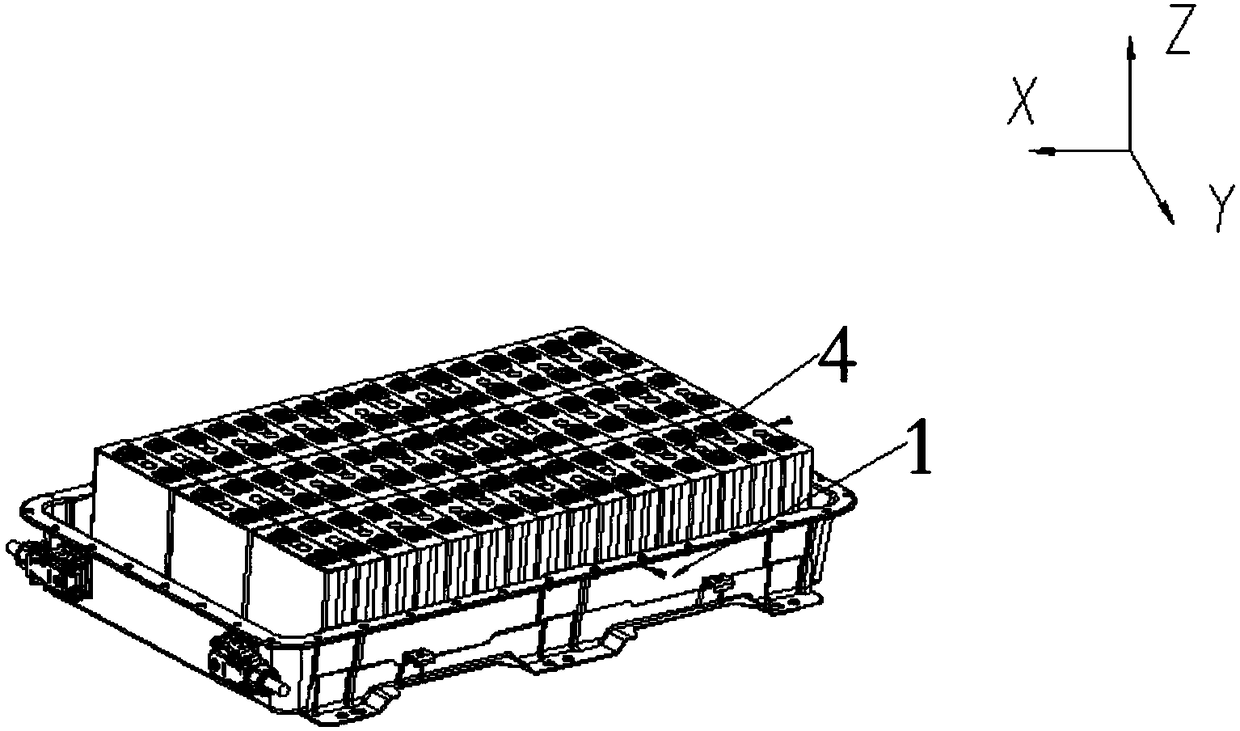

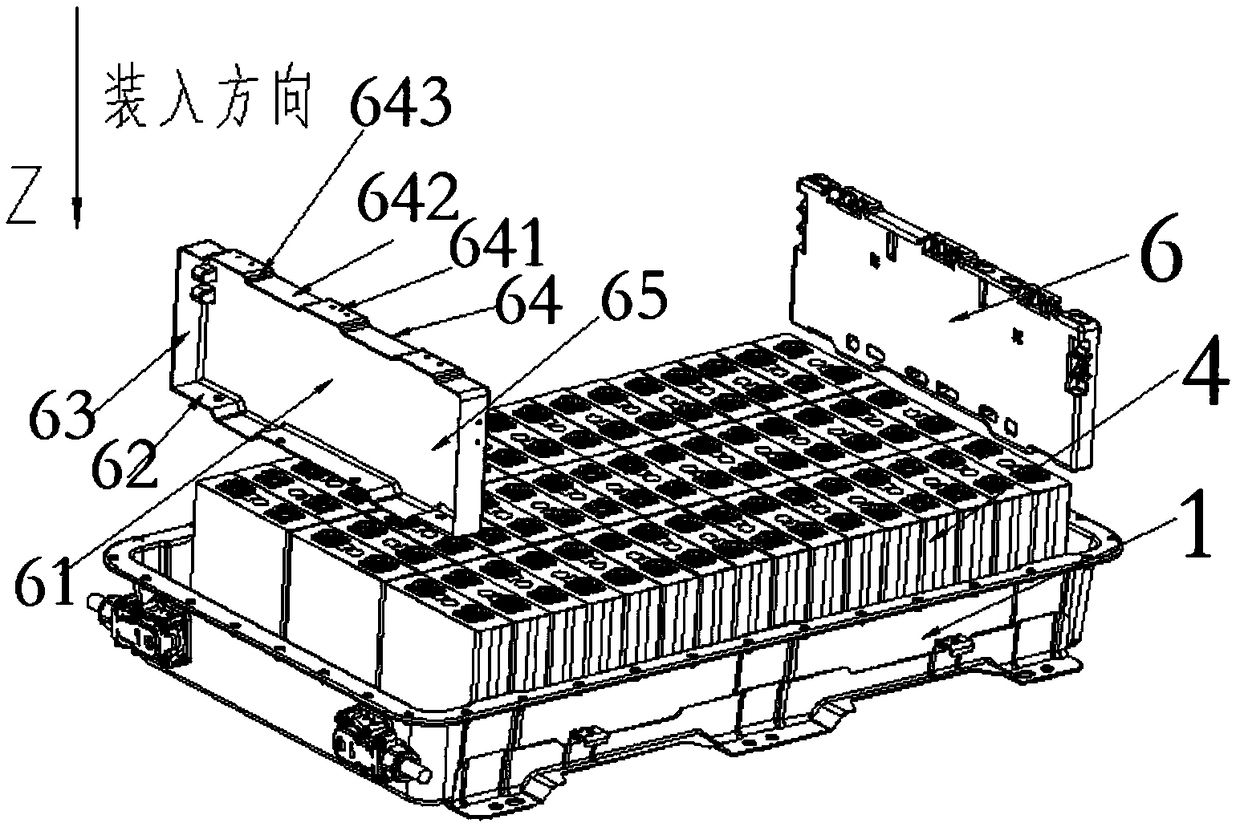

[0039] A new type of power battery pack structure. The battery pack structure includes a box body 1 for placing batteries 4. The upper end of the box body 1 is connected with a box cover 2 for protecting each battery cell 4 in the box body 1. Inside the box body 1 is placed a The battery pack, the battery pack includes a plurality of battery cells 4, the lower end of each battery cell 4 is connected to the bottom of the box body 1 through structural glue; the battery cells 4 are connected through a high-voltage connector 3, and through the above structure, this The structure of the battery pack disclosed in the invention has been greatly improved compared with the traditional one. Through such a structural setting, the technical solution disclosed in the present invention has a high group ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com