Fine-tuning fine boring tool holder and its adjustment method

A tool holder and fine boring technology, which is applied in the field of fine-tuning and fine-boring tool holders and adjustments, can solve the problems of lack of display numerical fine-tuning function and low adjustment accuracy, and achieve the goal of improving the efficiency of processed products, reducing complexity, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

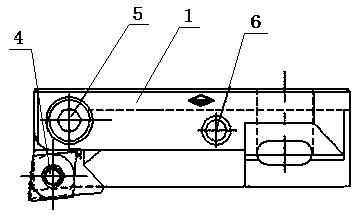

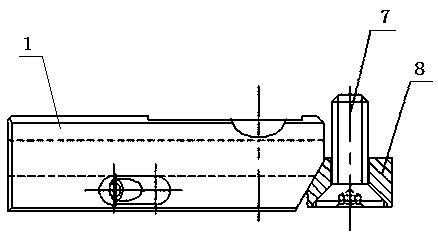

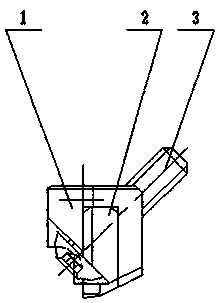

[0025] A fine-tuning fine-boring tool holder, which consists of: a tool holder body 1 with a blade holder 2 inside, the blade holder is a sliding body with a rectangular groove, and the tool holder body Fine-tuning bolts 5, cylindrical pins 6, and countersunk screws 4 are respectively installed on the front end surface. One side of the knife holder body has a slope, and the hexagon socket head screw 3 is installed on the slope. The knife holder body The inclined surface on the other side is equipped with an adjustment block 8, and the lower plane of the adjustment block is equipped with a hexagon socket head screw 7.

Embodiment 2

[0027] According to the fine-tuning fine boring tool holder described in Embodiment 1, the adjustment precision of the fine-tuning bolt is Φ0.01mm / grid, and the radial adjustment stroke is 0.3mm.

Embodiment 3

[0029] A fine-tuning and fine-tuning boring tool holder and an adjustment method thereof. The method firstly fixes the fine-tuning boring tool holder and the tool, installs the fine-tuning boring tool holder accurately, and fixes the tool on the tool holder by tightening the hexagon socket flat head screw;

[0030] To adjust the fine-tuning boring tool seat, when adjusting the axial direction, use a wrench to adjust the rotation and length of the hexagon socket head screw, thereby changing the compression degree of the adjustment block and changing the axial position of the tool seat; on the fine-tuning boring tool seat , by adjusting the compression degree of the adjustment block, the axial S1=±1.5mm adjustment range can be realized;

[0031] During the radial adjustment, it is adjusted by the fine-tuning bolt, and the scale display structure shows that the adjustment accuracy is Φ0.01mm / grid, and the radial adjustment amount is S2=0.3mm, so as to change the radial position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com