High-temperature insulating layer for engine blade film sensor and preparation method of high-temperature insulating layer

A thin film sensor and engine blade technology, applied in the coating, superimposed layer coating, vacuum evaporation coating and other directions, can solve the problems of reducing the high temperature insulation performance of the thin film, high stress, easy to generate leakage current, etc., to ensure electrical insulation. performance, good gap filling performance, the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

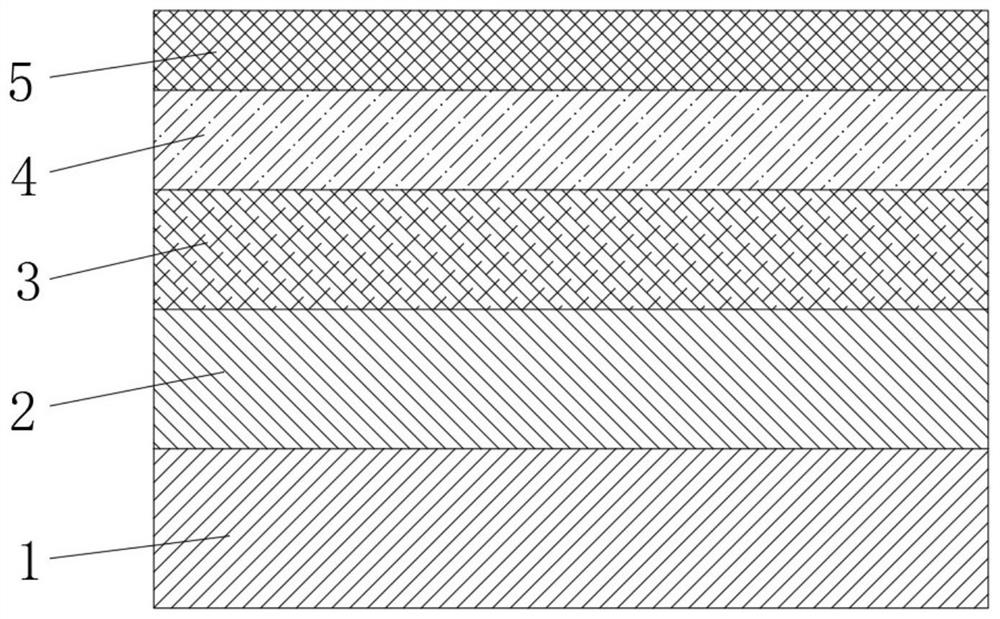

[0031] A high-temperature insulating layer for an engine blade film sensor of the present invention, comprising a blade base layer 1, a high-temperature oxide layer 2, an Al 2 o 3 Thin film layer 3, Ta 2 o 5 Thin film layer 4 and Si 3 N 4 Film layer 5.

[0032] In this embodiment, the thickness of the high temperature oxide layer 2 is 1 μm, and the Al 2 o 3 Thin film layer 3 has a thickness of 1 μm, Ta 2 o 5 Thin film layer 4 has a thickness of 2 μm, Si 3 N 4 The thickness of the film layer 5 is 3 μm.

[0033] In this embodiment, the high-temperature insulating layer for the engine blade film sensor can work normally at 800° C. to 1500° C.

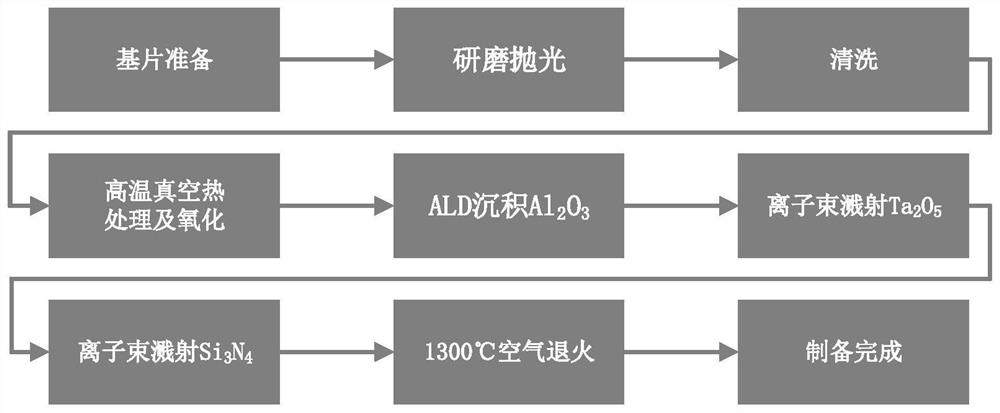

[0034] A method for preparing a high-temperature insulating layer for an engine blade film sensor of the present embodiment comprises the following steps:

[0035] S1. Grinding and polishing treatment of the surface of the base material: use 2000#, 3000#, 5000# metallographic sandpaper to grind for 1 hour respectively, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com