A support structure for insulating and encapsulating a temperature sensing head

A technology of support structure and sensor head, applied in the direction of thermometers, thermometers, measuring devices, etc., which are directly sensitive to heat-sensitive electrical/magnetic components, can solve the problems of insufficient insulation, high cost, lack of fixed structure, etc., to ensure The effect of electrical insulation, reasonable structure and easy injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described below with reference to the drawings and embodiments.

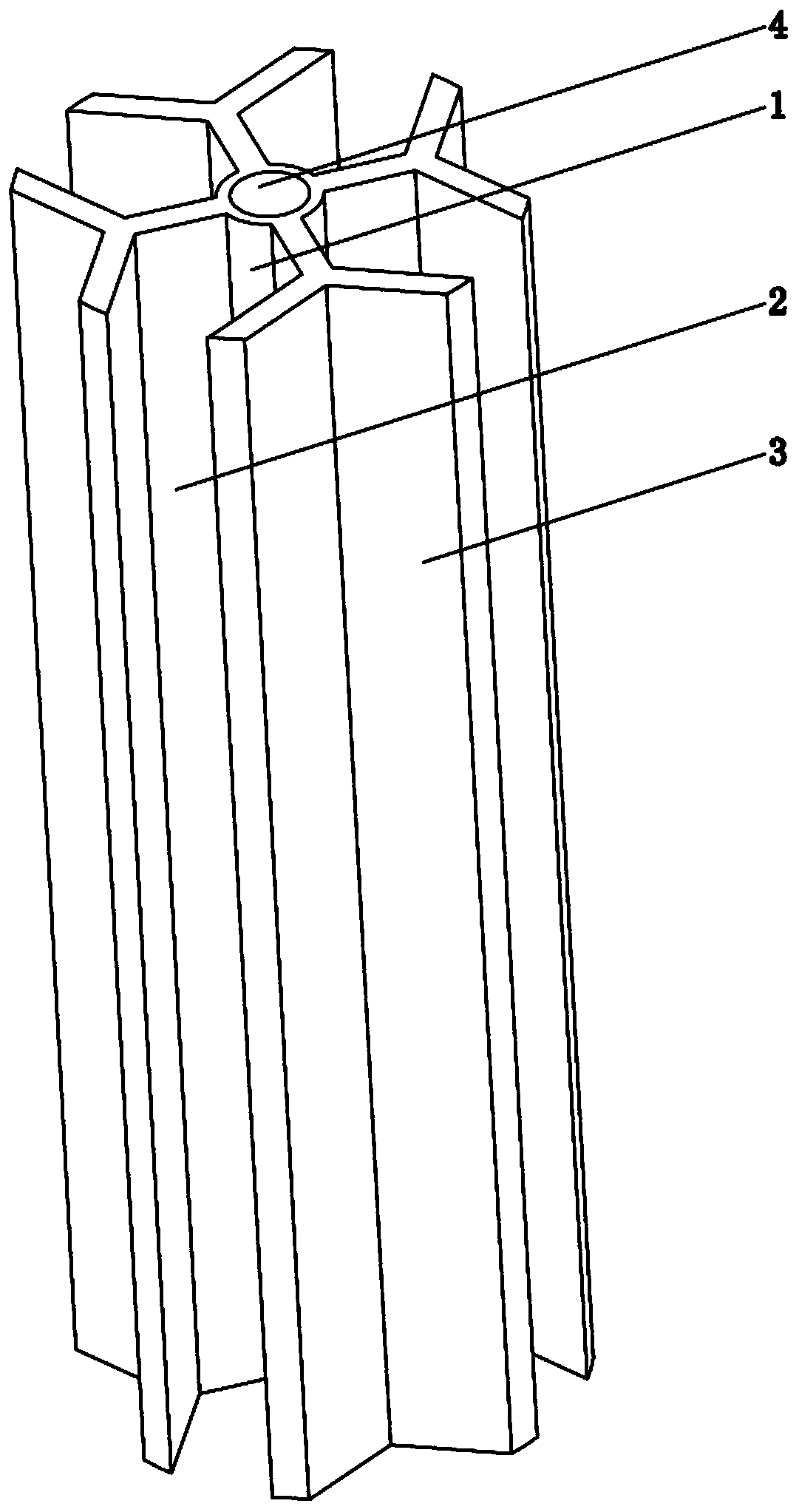

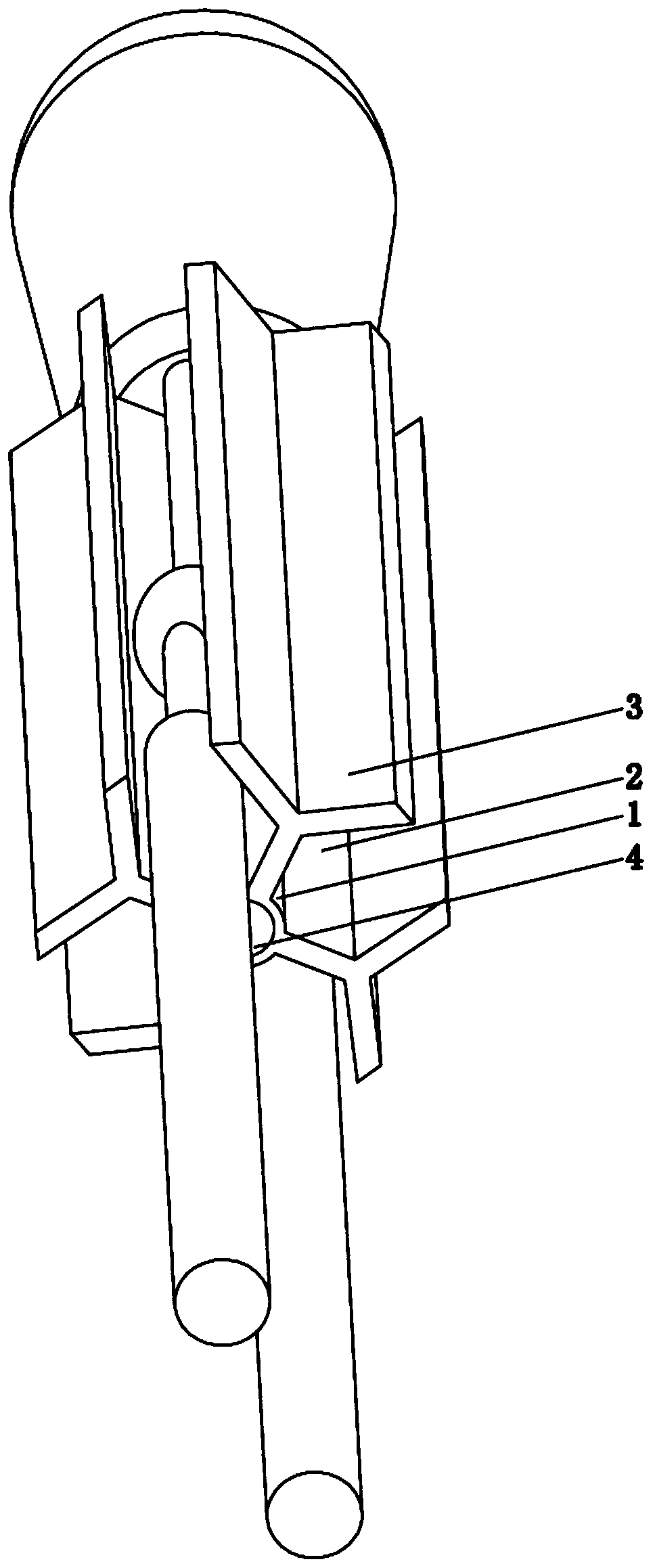

[0018] Such as figure 1 As shown, the insulating package support structure for a temperature sensing head according to the present invention includes a body 1 with a certain length. The body 1 is provided with N partition plates 2, where N is an even number greater than 3, and N partition plates 2 are arranged at equal angular intervals along the outer edge of the main body 1; the outer end of the partition plate 2 is provided with two supporting pieces 3, and the two supporting pieces 3 extend symmetrically to both sides of the partition plate 2 to form a "Y" shape with it The one-piece structure; the isometrically distributed partition plate 2 divides the sensor cavity, two adjacent partition plates 2 and the two opposite support pieces 3 form an open clamping structure, and then in the sensor cavity An independent channel cavity is constructed. The N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com