Production technology of low-density flexible paper used for molded insulators of extra/ultra high voltage transformers

A production process and transformer technology, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., can solve problems such as poor mechanical properties and electrical properties, achieve simplified production processes, improve cleanliness, improve electrical properties and mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is the specific embodiment of the present invention, and each of the following raw materials is calculated according to the ratio of mass and number:

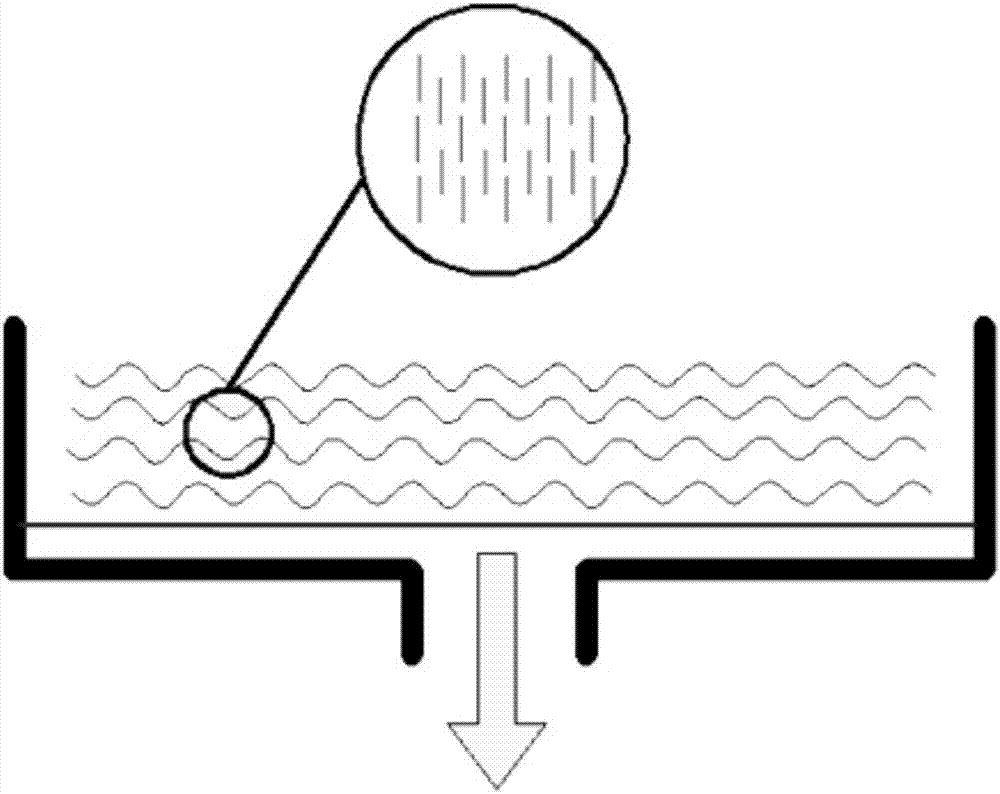

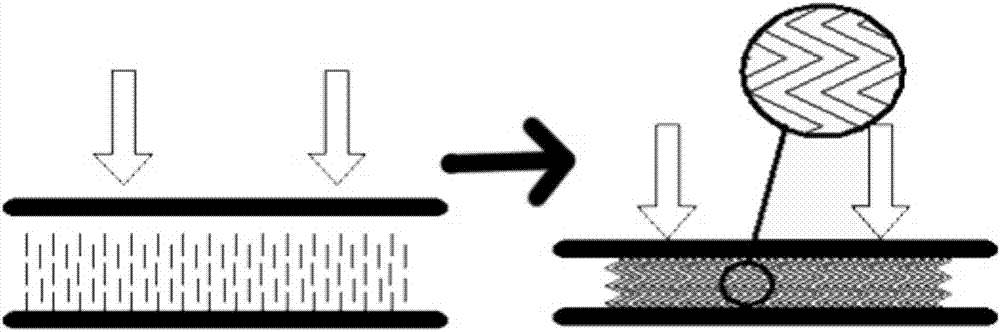

[0014] A production process of low-density flexible paper used for forming insulating parts of ultra / ultra-high voltage transformers, which comprises the following steps: 1) mixing and beating cotton fibers and wood fibers; 2) diluting the concentration of the slurry to 0.2-0.6%, removing the slurry Impurities and foreign matter in the clean slurry are dehydrated to increase the concentration of the slurry to 2-5%; 3) as figure 1 As shown, adopt the vacuum negative pressure method to make the made wet paper embryo fibers vertically arranged; 4) as figure 2 As shown, the wet paper embryo is pressed in the thickness direction, and the fibers of the wet paper embryo are twisted to form a locked state after being pressed. The obtained low-density flexible wet paper is used for the production of molded insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com