A kind of multi-junction solar cell anti-reflection film and preparation method thereof

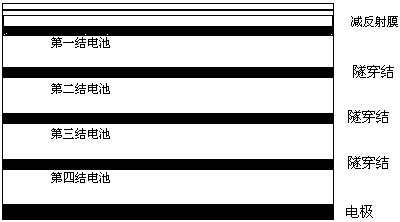

A technology of multi-junction solar cells and anti-reflection coatings, which is applied in the fields of circuits, photovoltaic power generation, electrical components, etc., can solve the problem that the research on wide-spectrum anti-reflection coatings of multi-junction solar cells is almost blank, and achieve the effect of meeting the needs of aerospace applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

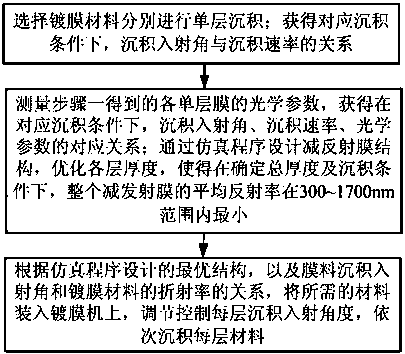

[0021] This embodiment specifically includes the following steps, such as figure 1 Shown:

[0022] Step 1. Select the coating material to carry out single-layer deposition respectively; obtain the relationship between the deposition incident angle and the deposition rate under the corresponding deposition conditions; the coating material can be selected from commonly used materials for solar cell reflective films, such as TiO 2、 SiO 2 、Al 2 o 3 Wait.

[0023] Step 2, measure the optical parameters of each single-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com