Reverse-flow full-automatic battery grouping method and reverse-flow full-automatic battery grouping system based on dynamic optimization

A dynamic optimization, fully automatic technology, applied in the direction of secondary battery repair/maintenance, measurement of electricity, measurement of electrical variables, etc. The effect of improving the efficiency and quality of the combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

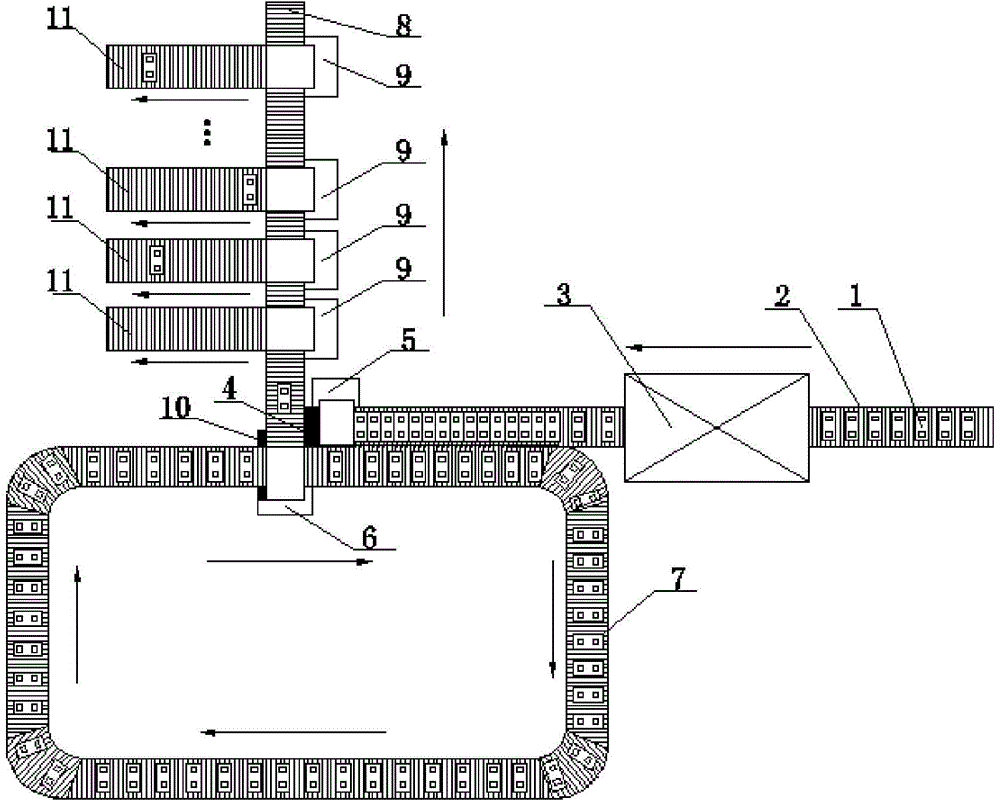

[0045] See attached figure 1 As shown, a dynamic optimization-based reflow fully automatic battery assembly system includes a battery performance detection device 3, a conveying device and a main control machine.

[0046] The conveying device is mainly composed of an input conveyor belt 2, an endless conveyor belt 7, an output conveyor belt 8 and an exit conveyor belt 11, wherein the input conveyor belt 2 and one side of the endless conveyor belt 7 are parallel and connected to each other, the endless conveyor belt 7 and the output conveyor belt 8 are perpendicular to each other and connected, and the output conveyor belt 8 and the outlet conveyor belt 11 are perpendicular to each other and connected.

[0047] A battery performance detection device is installed on the input conveyor belt to detect battery performance parameters.

[0048] A baffle 4 is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com