Solder spacer and electronic module comprising such a spacer

一种电子卡、焊料的技术,应用在电气连接印刷元件、堆叠隔开印刷电路板、用电元件组装印刷电路等方向,能够解决机械强度较差再现性、小机械强度、很难自动组装等问题,达到提高可再现性、增加拧紧力矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

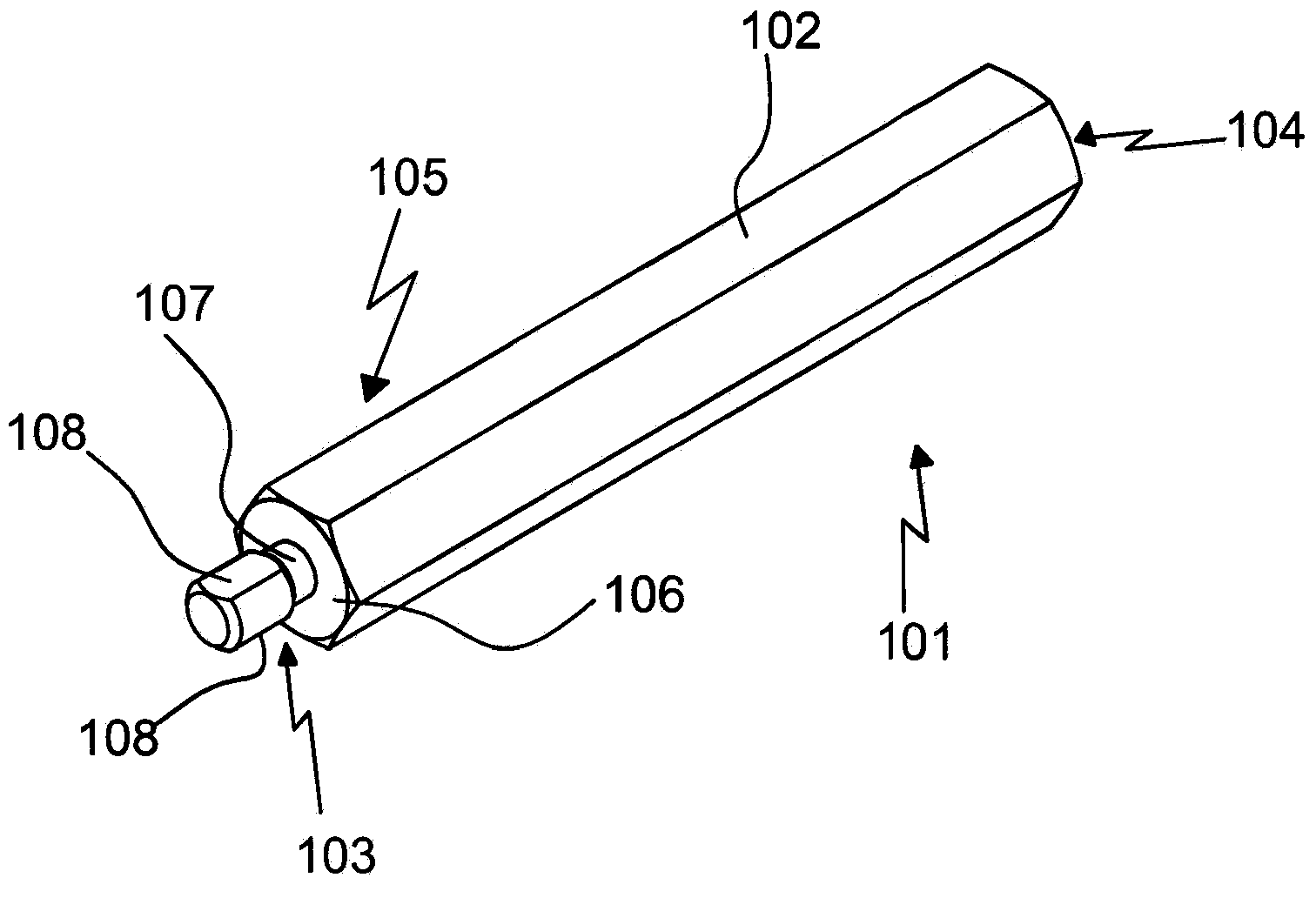

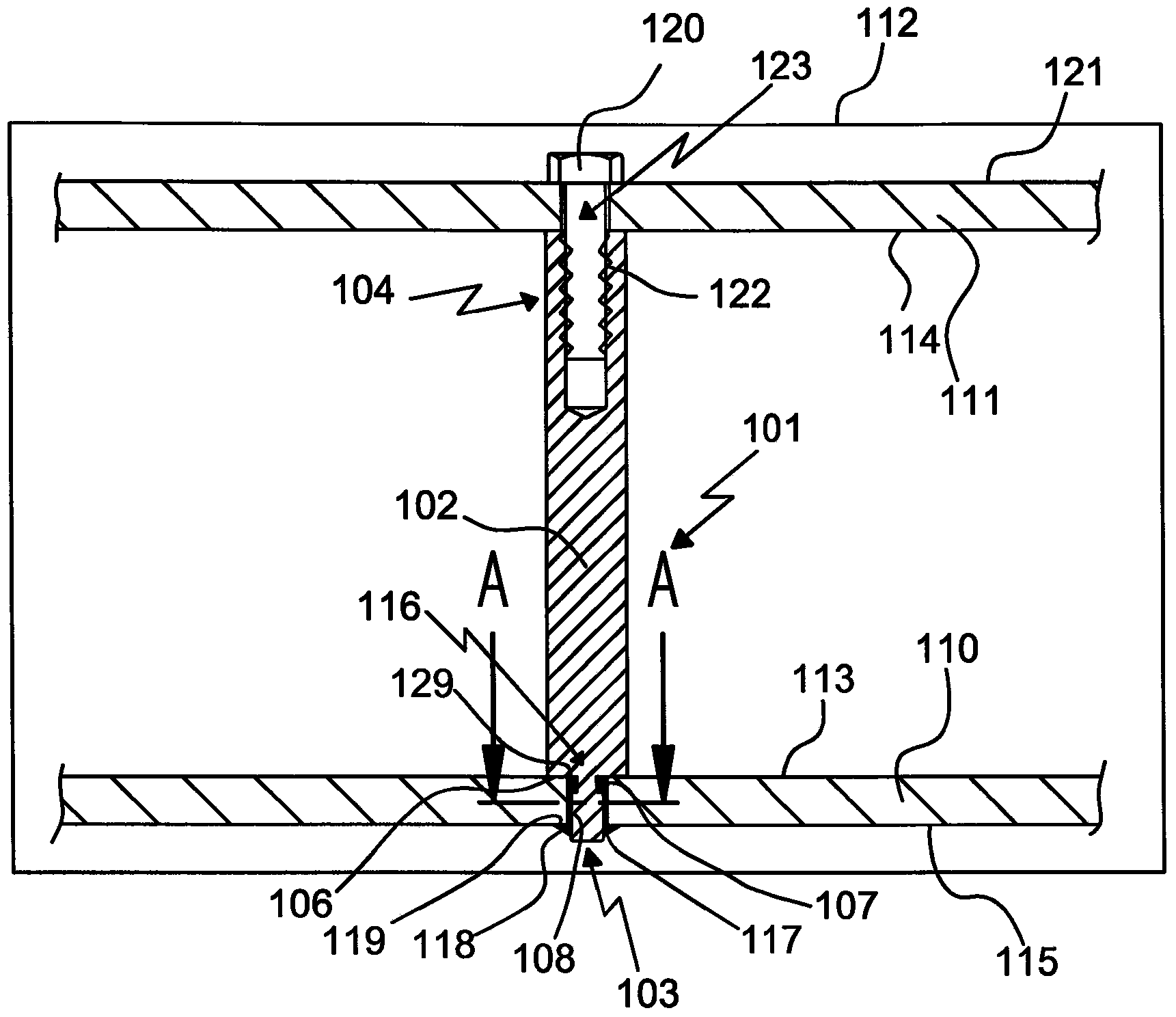

[0019] refer to figure 2 , the spacer 101 for welding of the present invention includes an elongated body with a hexagonal cross-section and a centering post 103 with a substantially cylindrical shape. The elongated body 102 has a threaded end 104 and an opposite end 105 provided with a transverse bearing surface 106 and with a centering post 103 projecting therefrom along the axis of the elongated body 102 . The centering post 103 is connected to a lateral bearing surface 106 via a circular groove 107 . The centering column 103 is provided with two longitudinally extending, symmetrically arranged outer flats 108 .

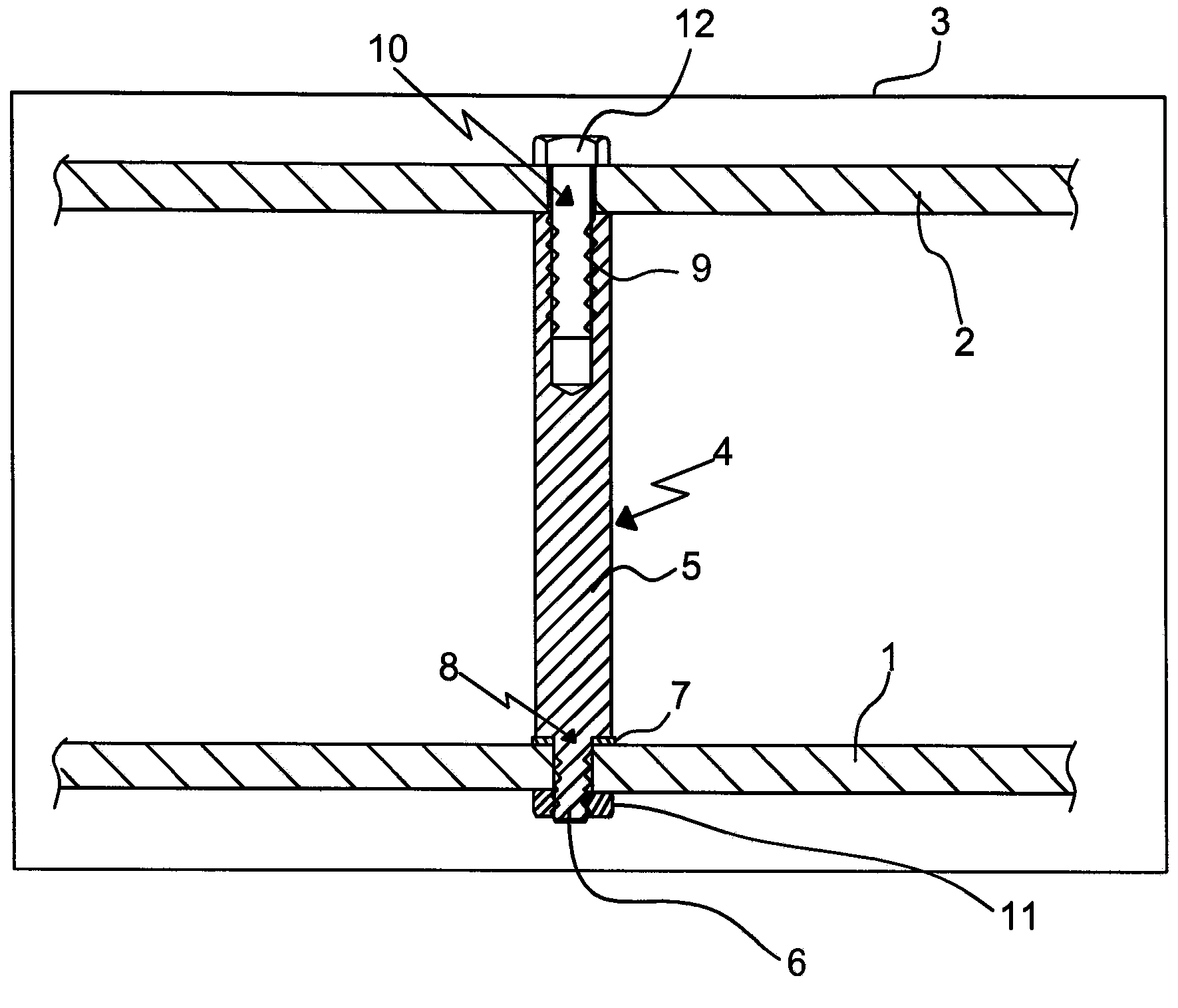

[0020] refer to image 3 and Figure 4 , the spacer 101 for soldering of the present invention is used in this example to assemble the first electronic card 110 and the second electronic card 111 of the electronic module 112 together. The elongated body 102 of the spacer 101 for welding is installed between the inner surface 113 of the first card 110 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com