Multi-point synchronous automatic pre-welding scanning type laser tracking method and device for welded joint of pipeline

A laser tracking, synchronous and automatic technology, applied in auxiliary devices, tubular objects, welding equipment, etc., can solve the problems of high cost, difficult control, and heavy mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

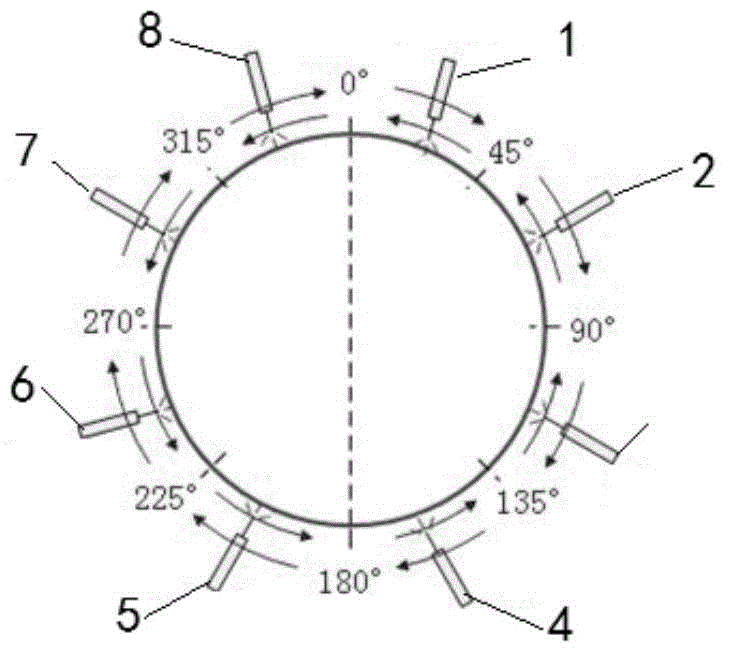

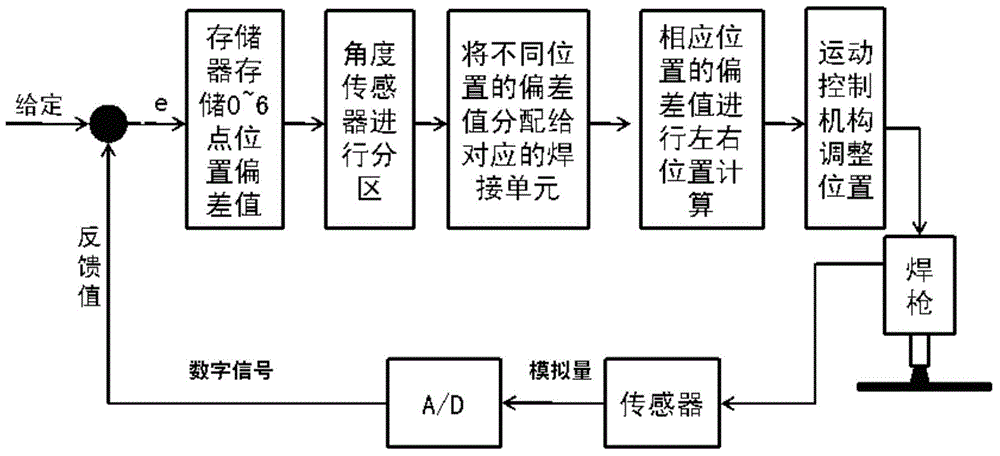

[0020] Example 1: Such as figure 1 , figure 2 As shown, the pipeline multi-point synchronous automatic welding pre-scanning welding seam laser tracking device, #1 welding torch 1, #2 welding torch 2, #3 welding torch 3, #4 welding torch 4, #5 welding torch 5, #6 Welding torch 6, #7 welding torch 7 and #8 welding torch 8 are located outside the circumference of the worktable, #1 welding torch 1, #2 welding torch 2, #3 welding torch 3, #4 welding torch 4, #5 welding torch 5. The angle between #6 welding torch 6, #7 welding torch 7 and #8 welding torch 8: the angle between #1 welding torch 1 and #2 welding torch 2 is 45 degrees, #3 welding torch 3 and # 2 The angle between welding torch 2 is 45 degrees, the angle between #3 welding torch 3 and #4 welding torch 4 is 45 degrees, the angle between #4 welding torch 4 and #5 welding torch 5 is 45 degrees, The angle between #5 torch 5 and #6 torch 6 is 45 degrees, the angle between #6 torch 6 and #7 torch 7 is 45 degrees, and the angl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap