Die with workpiece delivery error prevention mechanism

A technology of misfeeding and moulding, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of scrapped workpieces, affecting production efficiency, product qualification rate, mould damage, etc., to reduce work intensity, easy operation, and improve work The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

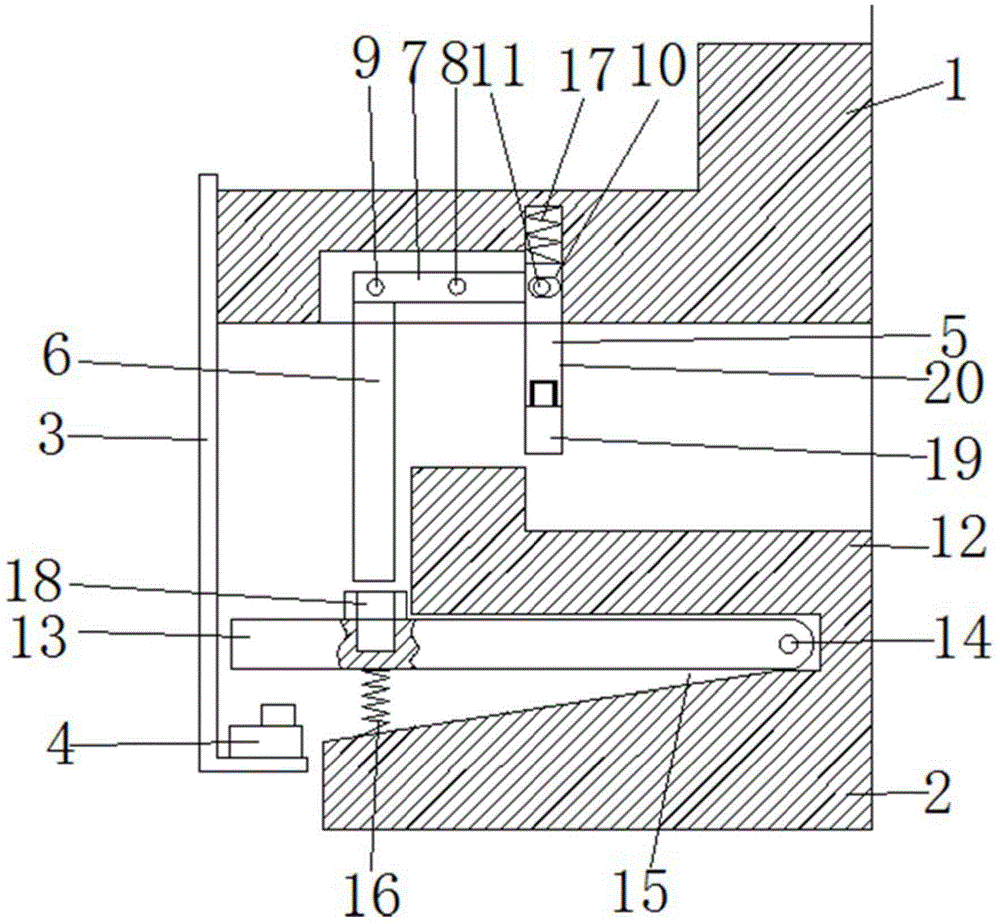

[0012] A mold with a mechanism for preventing workpiece misfeeding, including an upper mold 1 and a lower mold 2, the upper mold 1 includes an L-shaped bracket 3, a normally closed limit switch 4, a first push rod 5, and a second push rod 6 , the first lever 7, the L-shaped bracket is fixed on the left side of the upper mold 1, and the bottom edge of the L-shaped bracket 3 is equipped with a normally closed limit switch 4, and the first lever 7 is movable with the upper mold 1 through the first pin 8 Connection, one end outside the first lever 7 is flexibly connected to one end of the second push rod 6 through the second pin 9, one end of the first push rod 5 is provided with a waist-shaped hole 10, and the other end of the first lever 7 is connected through the third pin 11 is movably connected with the waist-shaped hole 10 of the first push rod 5. The lower mold 2 includes a die 12, a second lever 13, and a pin 14. The die 12 is provided with a mounting groove 15 for installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com