Shot blasting device

A technology of shot blasting device and rotary drive device, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve the problems of high cost, inability to project materials to project objects, etc., achieves easy setting operation, avoids Effects of Design Changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

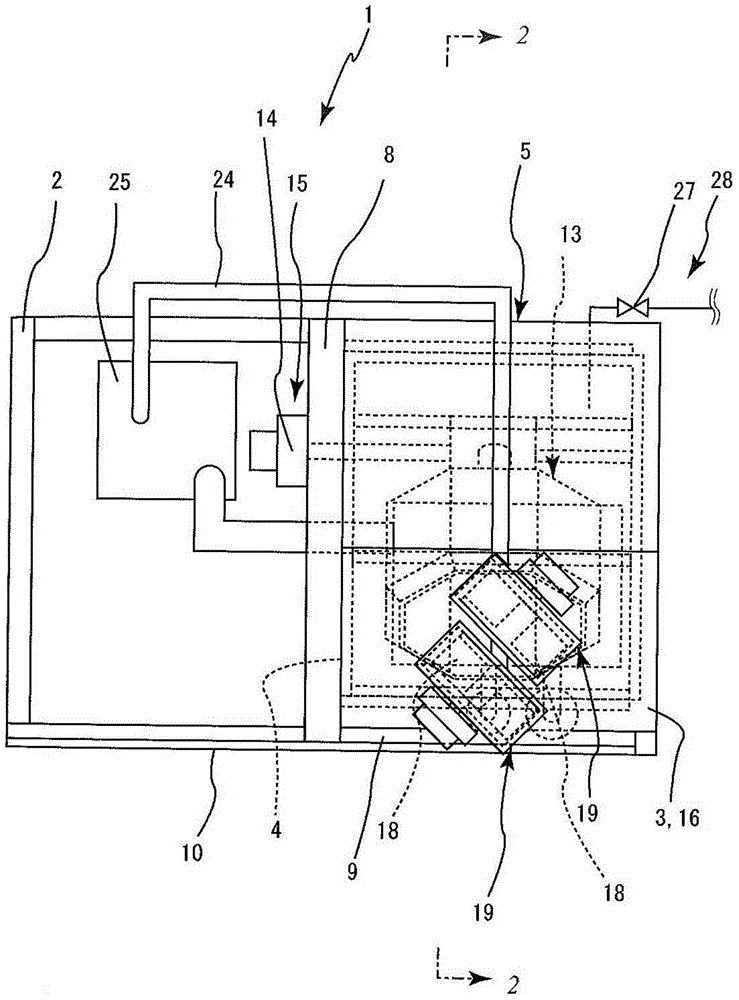

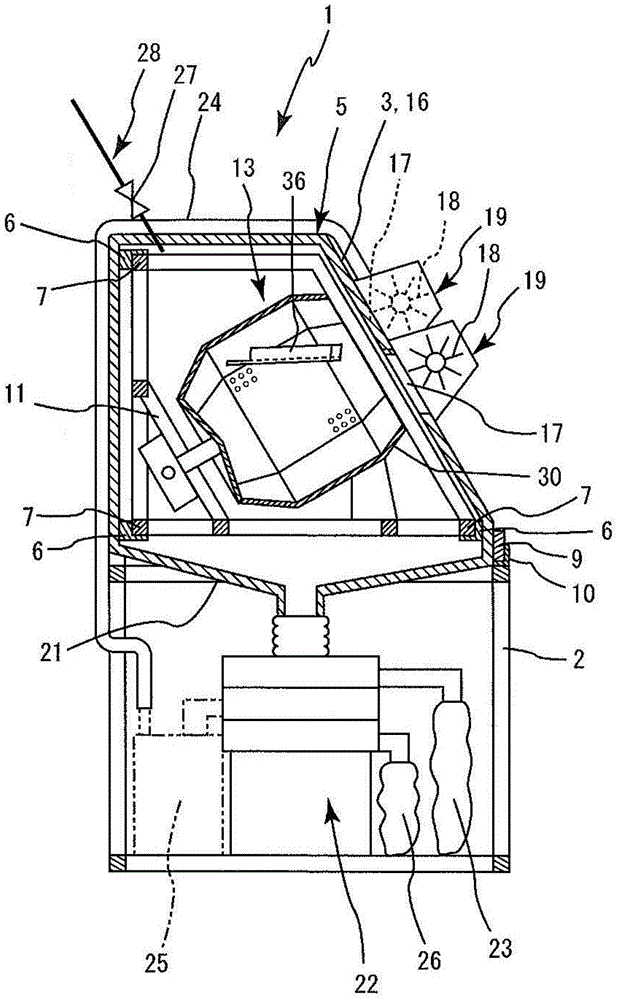

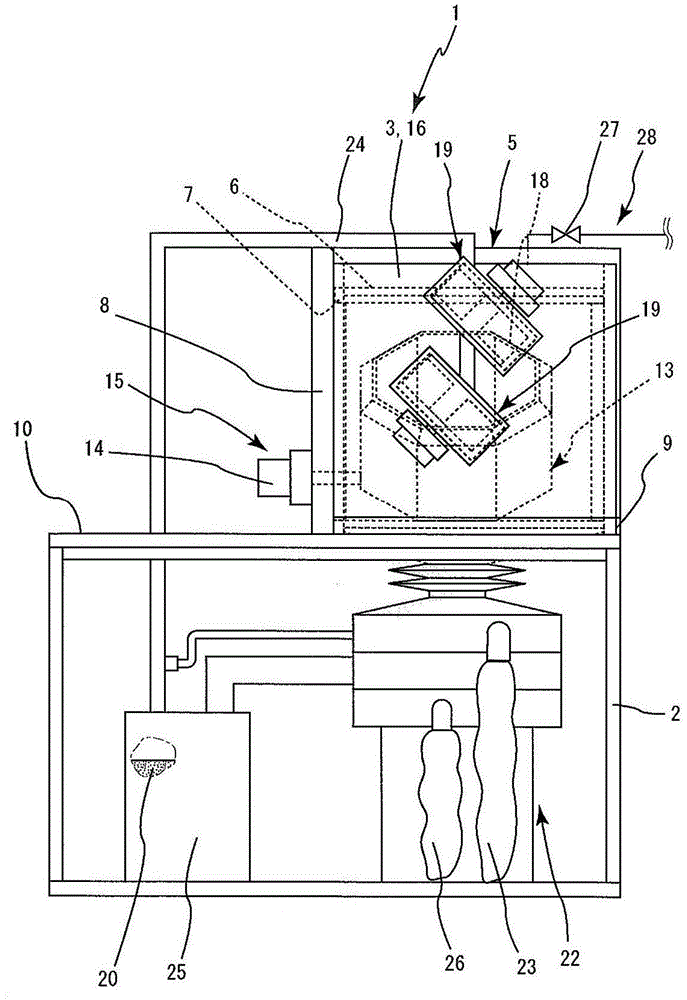

[0046] Hereinafter, the present invention will be described in detail with reference to embodiments for carrying out the present invention shown in the accompanying drawings.

[0047] exist Figure 1 to Figure 6 In the shown first embodiment for implementing the present invention, 1 is a large-scale shot blasting device of the present invention that removes burrs from a large molded product (processed object). The large-scale shot blasting device 1 includes: a frame-shaped Support platform 2; cover box 5, the upper front surface of the cover box 5 is formed as an inclined surface 3, and the upper front surface is arranged to cover the rear part of the central part of the support platform 2, and the cover box 5 is in the center An opening 4 is formed on the part side; an opening and closing cover 8 can be opened and closed to cover the opening 4 of the cover box 5, and a fixing device that can be fixed to the cover box 5 is installed on the opening and closing cover 8. Guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com