Molding method of storage tank installation plate pre-buried frame

A molding method and pre-embedded frame technology, which is applied in the field of pre-embedded frames for storage tank mounting plates, can solve the problems of high specific rigidity, high specific strength, and inability to meet the requirements of lightweight satellite structures at the same time, and achieve satisfactory mechanical properties and quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A method for forming a pre-embedded frame of a tank mounting plate, comprising the following steps:

[0027] The separate forming process of the thicker part of the embedded frame includes the following steps:

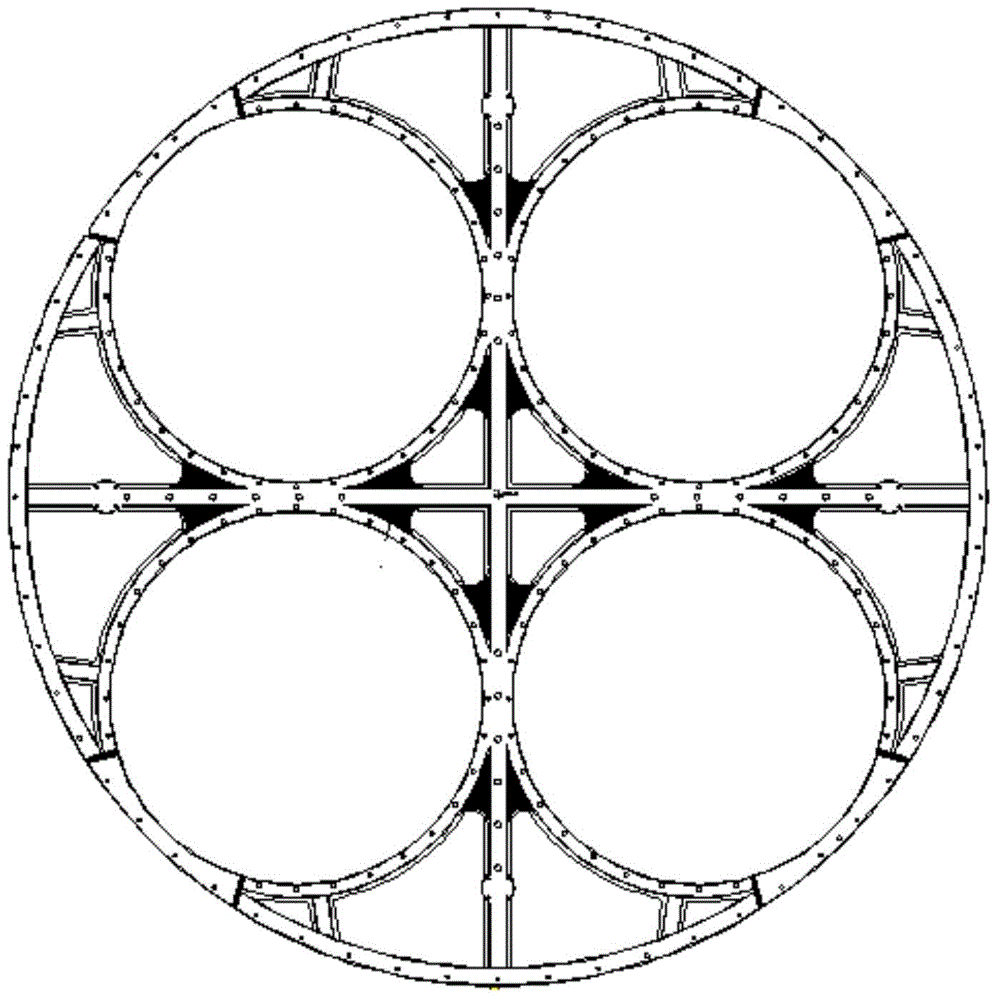

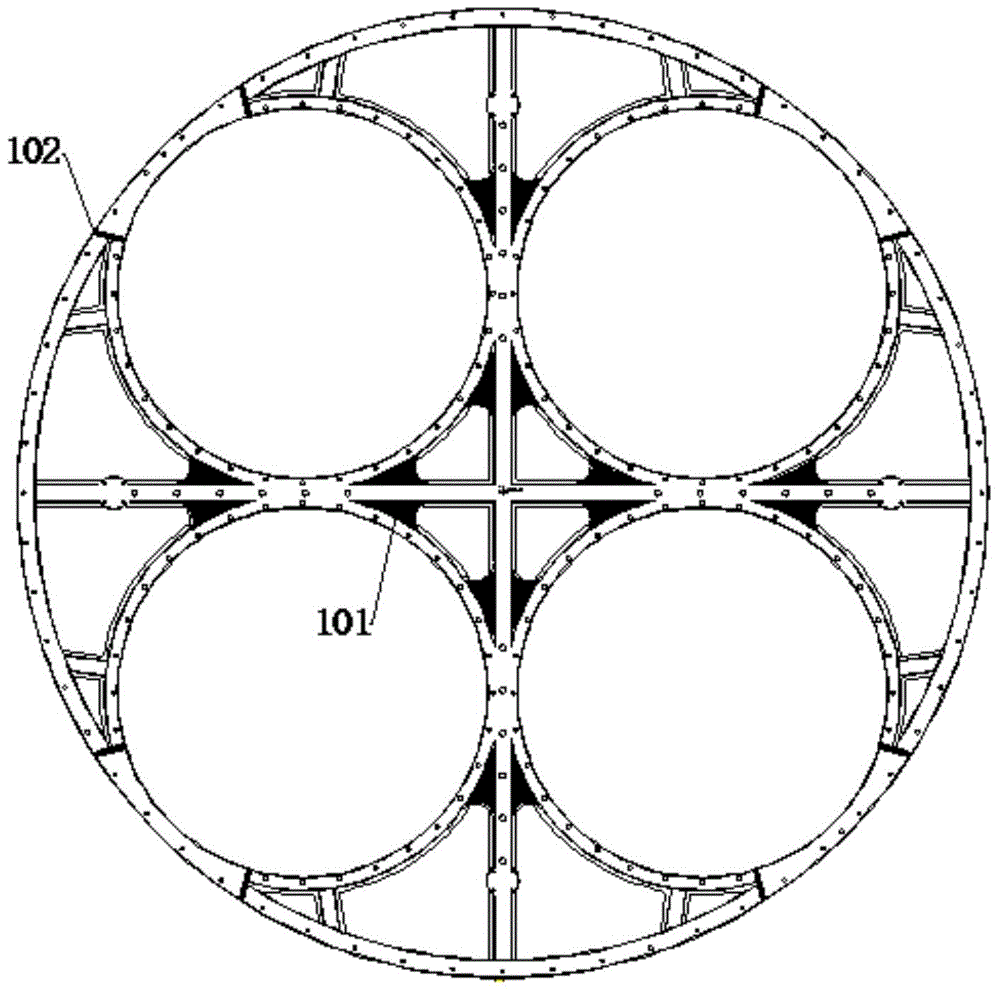

[0028] Step 1: Forming individually. like figure 2 As shown in the figure, according to the size requirements of the thicker part of the embedded frame, 16 101 parts and 8 102 parts are separately formed, and cured by heating and pressure to obtain a blank of the required size;

[0029] Step 2: Processing: Use machine tools or manually process structural parts 1 and 2 of the desired shape;

[0030] The molding process of the overall layering, molding, hot pressing and curing, and demoulding of the embedded frame includes the following steps:

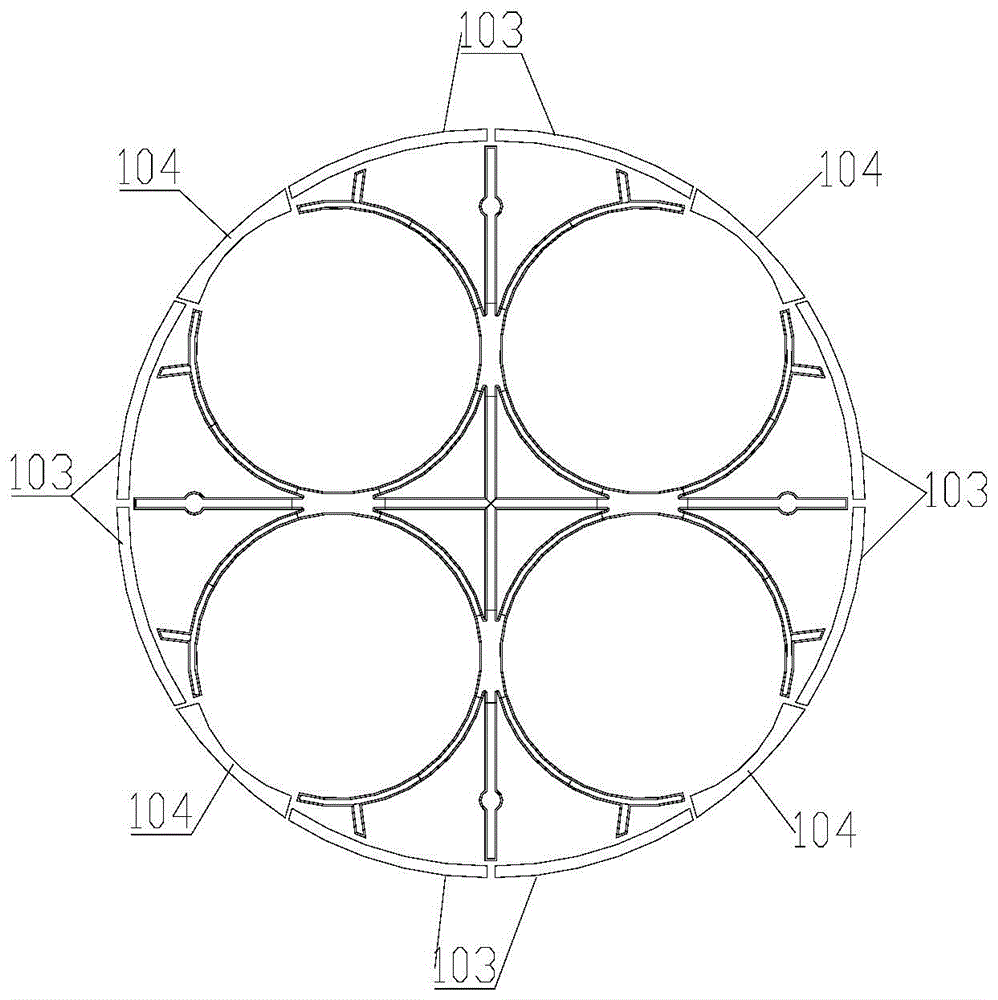

[0031] Step 1: Overall layering. Install the steel mold on the base, and the peripheral strips are not installed temporarily; the entire surface of the steel mold is continuously layered, and the peripheral layering a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap