An automatic lifting device

A lifting device and automatic technology, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of high labor intensity for operators and potential safety hazards for transporters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

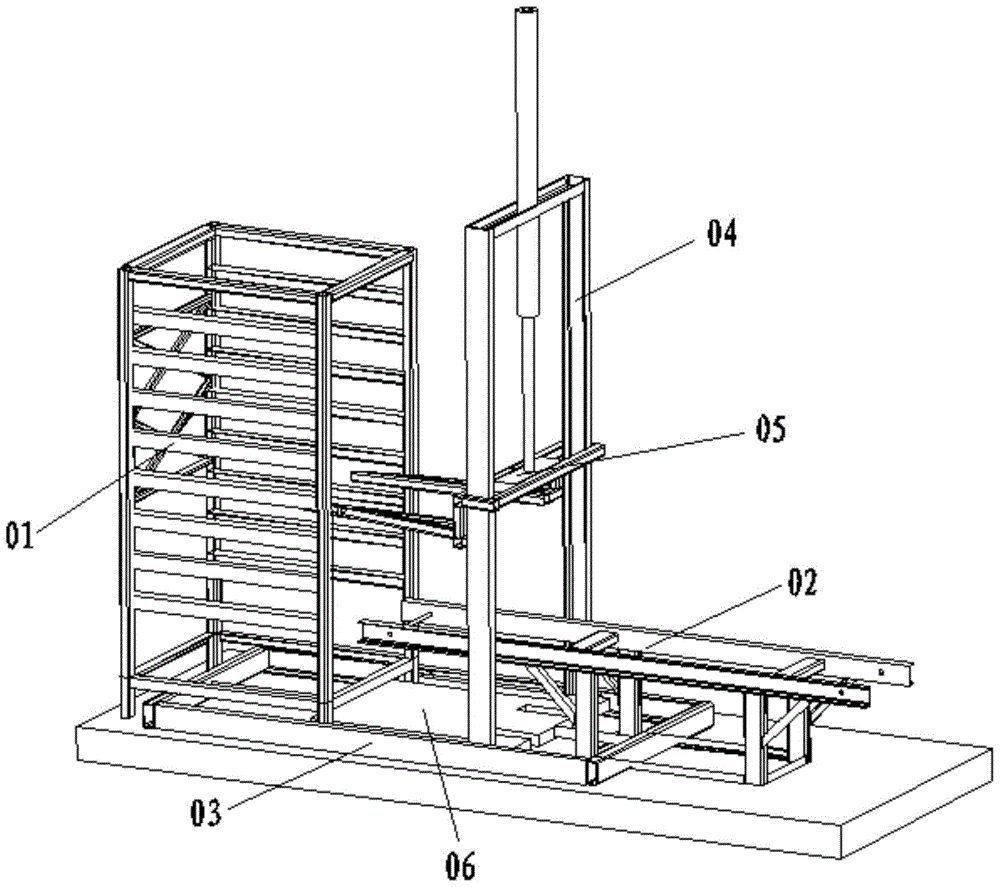

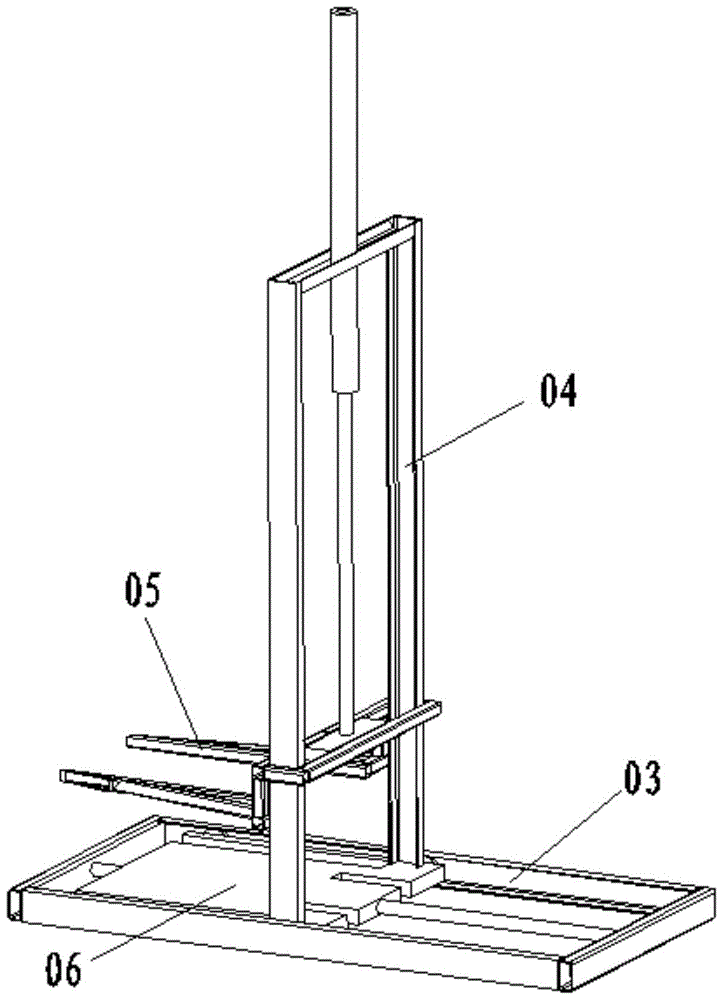

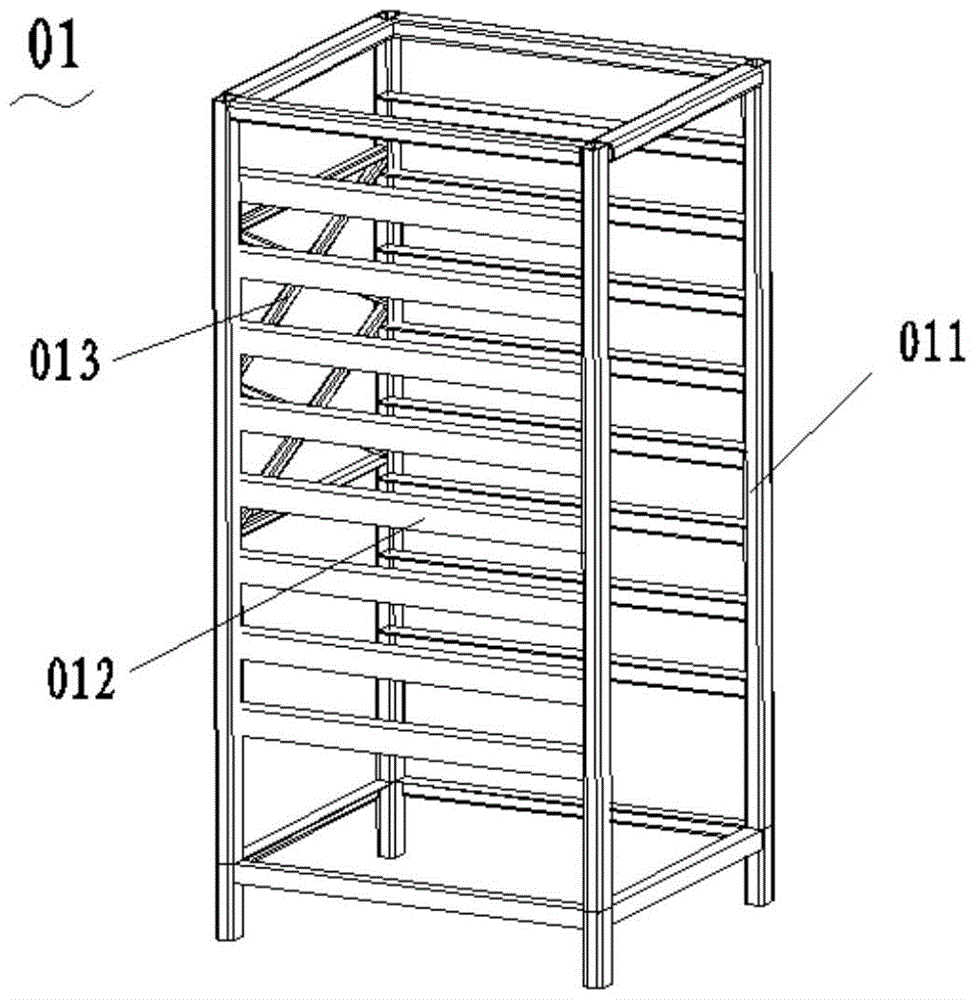

[0020] Such as Figure 1-2 As shown, the present invention provides an automatic transport lifting device, comprising: a transverse track 03, a storage cabinet 01 arranged on one side of the transverse track 03, a conveying mechanism 02 arranged on the other side of the transverse track 03, The traversing mechanism 06 cooperating and sliding with the transverse rail 03 , the vertical rail 04 cooperating with the traversing mechanism 06 , and the transport mechanism 05 that can move up and down along the vertical rail 04 .

[0021] The horizontal track 03 (such as Figure 5 shown) includes cross rails 031 arranged side by side and a cross bar 032 in the middle of the cross rails 031.

[0022] Such as Figure 6 As shown, the traversing mechanism 06 includes a moving plate 06...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com