5G intelligent manufacturing cleaning robot with base adjusting mechanism

An adjustment mechanism and intelligent manufacturing technology, applied in the field of robots, can solve problems such as inability to transfer products, limited use, and single function of cleaning robots, and achieve the effects of improving stability, height, and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

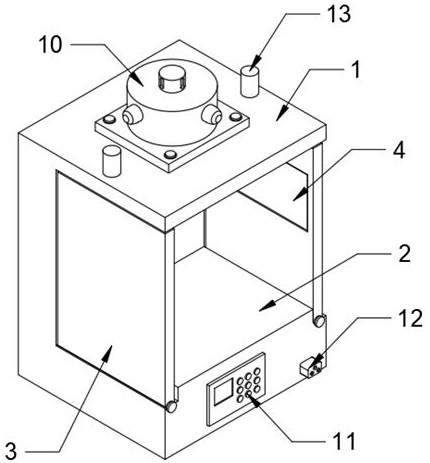

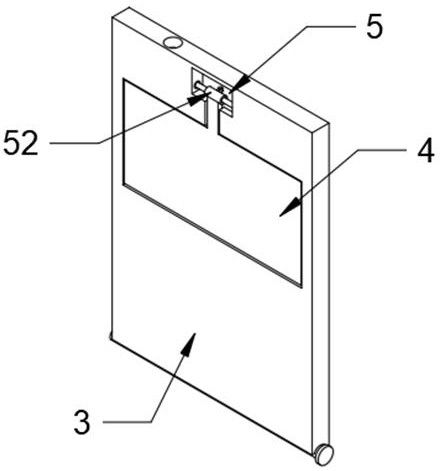

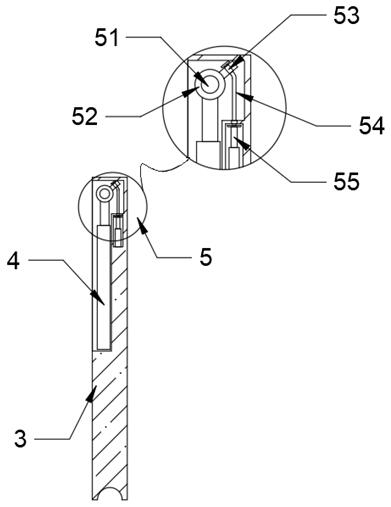

[0034] Such as Figure 1-7 As shown, a cleaning robot for 5G intelligent manufacturing with a base adjustment mechanism proposed by the present invention includes a robot body 1, a sensor assembly 10 is installed on the top of the robot body 1, and a control panel 11 is provided on one side of the robot body 1 to control One side of the panel 11 is provided with a charging head 12, and the bottom of the robot body 1 is also equipped with a moving wheel 166. One side of the robot body 1 is provided with a placement table 2, and the both sides of the placement table 2 are rotated and installed with a placement plate 3. One side of the plate 3 is rotated and installed with a protective plate 4, and the protective plate 4 and the placement plate 3 are connected by a turning mechanism 5 provided for rotation, and a cleaning mechanism 6 is installed in the robot body 1;

[0035]The cleaning mechanism 6 includes a mounting plate 61, a plurality of rotating rollers 62 are installed in...

Embodiment 2

[0038] like Figure 1-9 As shown, the present invention proposes a 5G intelligent manufacturing cleaning robot with a base adjustment mechanism. Compared with Embodiment 1, this embodiment also includes a robot body 1, a sensor assembly 10 is installed on the top of the robot body 1, and the robot body 1 is provided with a control panel 11, one side of the control panel 11 is provided with a charging head 12, one side of the robot body 1 is provided with a placing table 2, the two sides of the placing table 2 are rotated and installed with a placing plate 3, and the placing plate 3 The top of the robot body is provided with a limit slot. The top of the robot body 1 is equipped with a cylinder three 13. The output end of the cylinder three 13 runs through the top of the robot body 1 and is fitted with the limit slot. The cylinder three 13 is used to align the position of the placement plate 3 with the robot. The main body 1 is fixedly installed, a storage slot 56 is opened on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com