Ironing board

An ironing board and panel technology, which is applied in the field of ironing boards, can solve the problems of surface cracks, ironing holes, affecting the service life of the ironing board, etc., and achieves the effect of convenient ironing and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

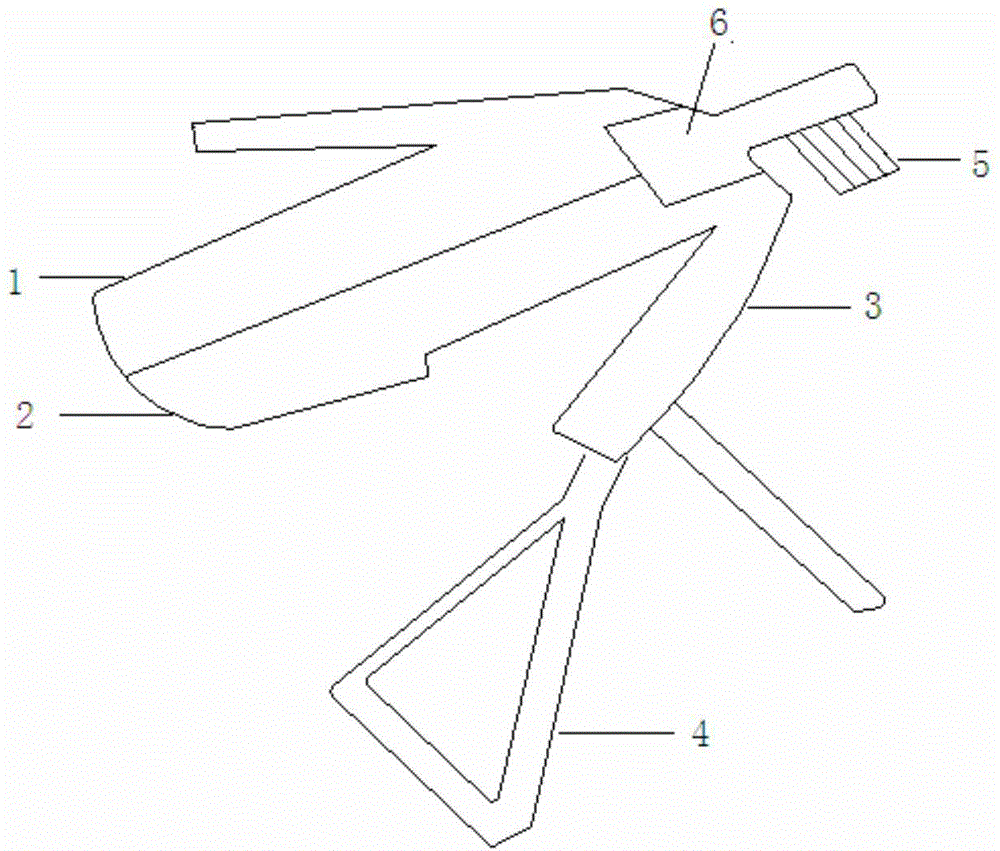

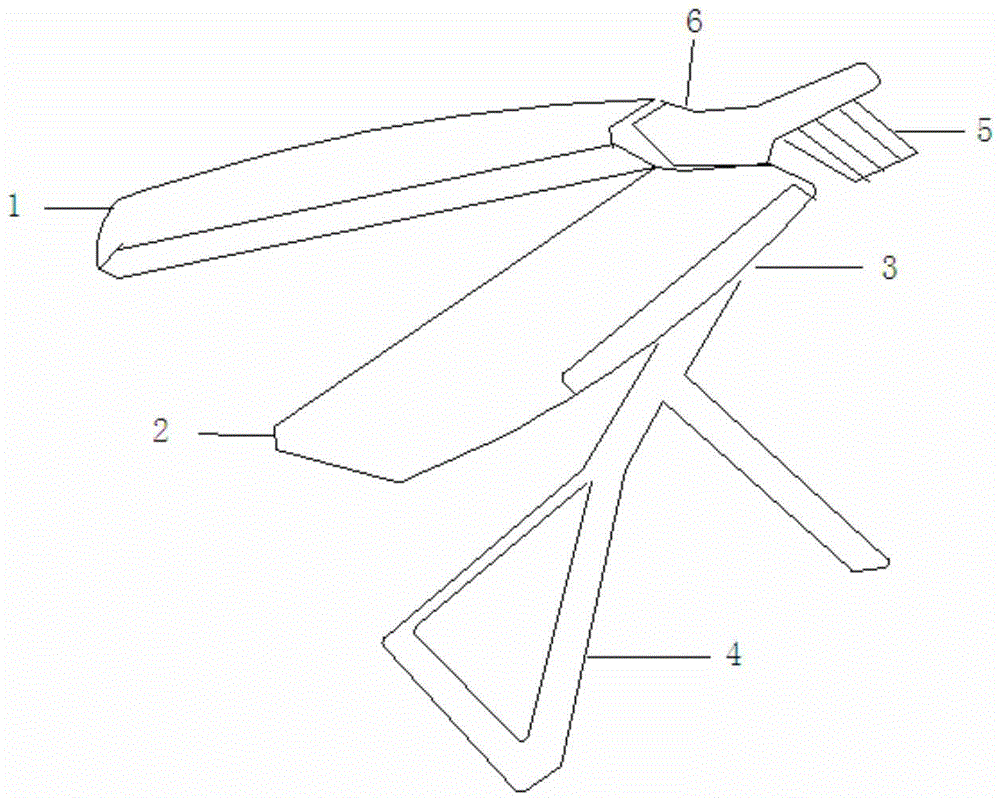

[0016] Such as figure 1 As shown, the present invention includes a first panel 1 , a second panel 2 , a connecting portion 6 and a foldable bracket 4 . The foldable bracket 4 is located at the bottom of the ironing board. When the ironing board is not in use, the bracket 4 can be folded to store the ironing board, which occupies less space.

[0017] Further, a support plate 5 is installed on the side of the ironing board, and the iron can be placed on the support plate 5 .

[0018] Further, the parts of the outer edges of the first panel 1 and the second panel 2 near the connecting portion 6 are equipped with a rotating arm 3, and the rotating arm 3 can rotate. At this time, the rotating arm 3 is on the same plane as the first panel 1 and the second panel 2 .

[0019] Further, the outer surface of the ironing board is covered with a layer of heat insulating material, the heat insulating material is aluminum silicate fiber, glass fiber or rock wool; the surface of the heat in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com